Powder Metallurgy Components Market – Snapshot

Powder metallurgy is a cost-effective method of forming precision net shaped metal components, which yield efficiently designed consumer and industrial products. Significant increase in automotive production in Asia Pacific, led by rapid urbanization and industrialization, is driving the global powder metallurgy components market.

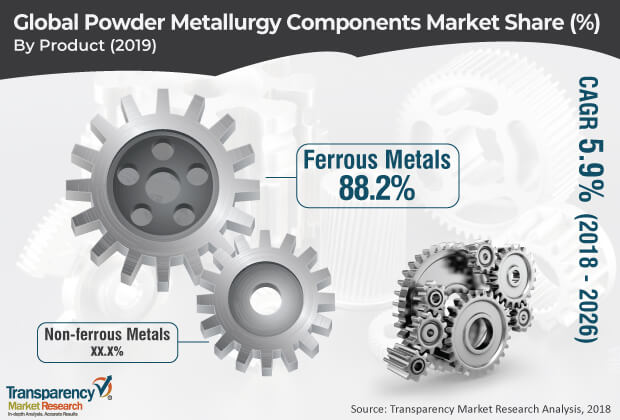

The global powder metallurgy components market has been segmented based on product and application. In terms of product, the market has been bifurcated into ferrous metals and non-ferrous metals. The ferrous metals segment has been further classified into iron and steel, while the non-ferrous metals segment has been categorized into aluminum and others (including copper, tungsten, and molybdenum). Ferrous metals was the leading segment of the global powder metallurgy components market in 2017.

Request Brochure @

https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=56565

Rise in usage of ferrous based powder metals in various applications such as magnetic assemblies, filtration systems, structural parts, sharp gemstone-grinding blades, and auto metal components is boosting the segment. Non-ferrous metal components impart high thermal and electrical conductivity, good machinability, high corrosion resistance, and good mechanical and fatigue properties. These components exhibit excellent compressibility due to lower sintering temperature compared to ferrous based powder metallurgy components. Increase in number of automotive companies and rise in disposable income of consumers, especially in emerging countries such as India and China, are likely to drive the non-ferrous metals segment of the powder metallurgy components market in the next few years.

In terms of application, the global powder metallurgy components market has been segregated into automotive, aerospace, medical, industrial, and others. Rise in demand for powder metallurgy components in engine (such as Variable Valve Timing [VVT] systems and oil pumps) and transmission applications (such as synchronizers and oil bearings) are boosting the demand for powder metallurgy components in the automotive industry. Industrial is also one of the promising segments of the global powder metallurgy components market.

REQUEST FOR COVID19 IMPACT ANALYSIS –

https://www.transparencymarketresearch.com/sample/sample.php?flag=covid19&rep_id=56565

Powder metallurgy components are employed in telecommunication equipment, computers, home appliances, lawn & garden equipment, farm/off-road equipment, power and hand tools, sporting goods, and firearms in the industrial segment. Rapid industrialization across the globe is expected to drive the industrial segment of the market in the near future. Aerospace and medical are lucrative segments of the market. Increase in demand for powder metallurgy components in additive manufacturing in the aerospace industry and manufacture of precision components such as gearing, gear boxes, small planetary devices, and medical dispensing devices in the medical industry are anticipated to propel the aerospace and medical segments during the forecast period.

In terms of region the global powder metallurgy components market has been split into North America, Europe, Asia Pacific, Latin America, and Middle East & Africa. North America was the leading consumer of powder metallurgy components in 2017. It was followed by Asia Pacific. The market in Asia Pacific is expected to surpass that in North America owing to the growth in automobile and electrical & electronic industries in the region. Rise in GDP, growth in research activities, and increase in investment in electric vehicles are estimated to boost the market in Asia Pacific in the near future. In 2017, Ford Motor Company and Zotye Auto announced plans to invest US$ 756 Mn to manufacture a range of electric vehicles for the automotive industry in China.

The U.S is projected to contribute significantly to the powder metallurgy components market in North America during the forecast period. Rise in consumer interest in electrical vehicles and emphasis on fuel efficiency of vehicles are encouraging manufacturers to design lightweight components. This is driving the powder metallurgy components market in the U.S.

Europe is also one of the prominent regions of the global powder metallurgy components market. Increase in focus on curbing carbon emissions and development of lightweight automotive parts are driving the market in the region. According to the European Aluminium Association (EAA), weight reduction of every 100 kg in cars provides 0.6 liters of fuel savings for every 100 km. Similarly, weight savings of 300 kilo grams can be achieved by using aluminum in a medium sized car with a weight of 1400 kilo grams. These factors are boosting the demand for powder metallurgy components in the region, especially in the automotive segment. The market in Latin America and Middle East & Africa is estimated to expand at a moderate pace due to the lack of awareness about the capabilities of the powder metallurgy technology among OEMs and high dependency on import of raw materials.

Key players operating in the global powder metallurgy components market include GKN Hoeganaes, Sumitomo Electric Company Ltd, and American Axle & Manufacturing Holdings, Inc. Companies have been striving to improve competitiveness by optimizing existing processes, merger & acquisitions, and developing new processes to lower environmental impact and improve quality of products. For instance, Miba AG is a leading global manufacturer and supplier of engine bearings. The company acquired the Industrial Bearing segment of the John Crane Group in 2017 in order to expand the business and production of industrial bearings.