Nanocrystalline Cellulose Market – Snapshot

Nanocrystalline cellulose is the elementary building block of natural cellulose available in the dimension of 10-9 meter (nanometer). It is a naturally occurring material isolated from cellulose of wood and various plants.

Demand for nanocrystalline cellulose materials from various end-user industries such as paper processing, composites manufacturing and biomedical are on the rise due to the superior properties such as high tensile strength, low density, and high degree of thermal stability. High surface area is a key property of nanocrystalline cellulose which helps it to have powerful interaction with the surrounding species such as water, organic compounds, and polymeric compounds.

Paper processing is the major end-user segment of the nanocrystalline cellulose market. When nanocrystalline cellulose is used in the paper products, it helps improving fiber to fiber bond strength and can be used as a barrier in grease-proof type papers.

Nanocrystalline cellulose can be prepared from inexpensive renewable biomass. Nanocrystalline cellulose has low toxicity and poses no serious environmental concerns; therefore, it can be used as a reinforcing agent for industrial biocomposites.

Request Brochure @

https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=6844

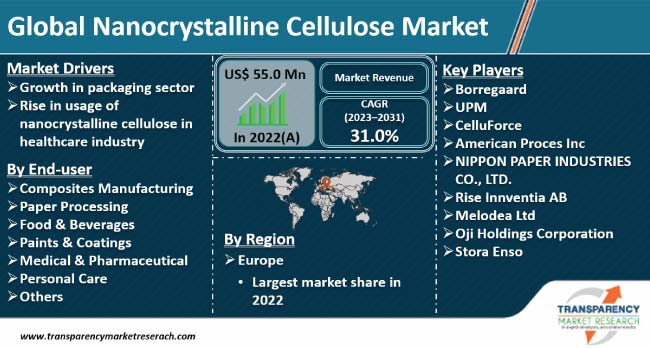

It can be utilized in several end-user industries such as composites manufacturing, paper processing, food & beverage, personal care, paints & coatings, and pharmaceuticals. Emerging end-user industries include oil & gas, construction, and textiles. In terms of consumption, North America and Europe dominate the global nanocrystalline cellulose market. Asia Pacific is anticipated to create lucrative opportunities in the nanocrystalline cellulose market due to increase in demand for biodegradable products from developed economies. Continuous technological innovations, advancements made in the personal care and pharmaceutical sectors, and rise in focus on biodegradable products are propelling the demand for nanocrystalline cellulose.

REQUEST FOR COVID19 IMPACT ANALYSIS –

https://www.transparencymarketresearch.com/sample/sample.php?flag=covid19&rep_id=6844

Governments across the globe are increasingly investing in the nanomaterial research and developmental activities. Governments of countries such as the U.S, Canada, Sweden, Australia, and Japan have initiated research and development activities for promoting the production of nanocrystalline cellulose on pilot and commercial scales in the last decades. The mission P3 Nano, initiated by the U.S and Canada governments encourage manufacturers to strategize their business through public-private partnerships, is anticipated to boost the nanocrystalline cellulose market in North America. Superior structural properties of nanocrystalline cellulose are likely to increase their use in various end-use industries. This, in turn, is projected fuel the demand for nanocrystalline cellulose across the globe. Nanocrystalline cellulose is used in several industrial applications such as composites, viscosifiers, and rheology modifier. This, in turn, is expected to create lucrative opportunities in the nanocrystalline cellulose market. Key applications of nanocrystalline cellulose include oil & gas, textiles, and construction.

Demand for nanocrystalline cellulose is high in various end-user industries; however, high capital cost inhibits manufacturers from capacity expansion. Commercial nanocrystalline cellulose is produced by the acid hydrolysis or enzymatic hydrolysis of cellulose fibrils and the method requires high manufacturing cost. The resulting product, nanocrystalline cellulose, does not contain amorphous part in its structure. Commercial production of nanocrystalline cellulose is still in the nascent phase. Large scale commercial production of nanocrystalline cellulose requires cost effective production and processing methods. Generally, capacity expansion of manufacturing plants require installation of advanced equipment, technology, and quality management systems. Unavailability of appropriate instrumental infrastructure is likely to hinder the mass production of nanocrystalline cellulose production. Availability of low cost substitute products is a major restraint of the nanocrystalline cellulose market. However, performance of nanocrystalline considered superior to other cellulose derived products such as cellulose ether and cellulose acetate

Manufacturers are striving to gain a competitive advantage in the market by acquiring advanced technologies. The nanocrystalline cellulose market is anticipated to expand considerably due to the introduction of sophisticated equipment. However, optimization of the manufacturing process of nanocrystalline cellulose requires in-depth research. Projects initiated by various governments are meant for devising methods for large scale production of nanocrystalline cellulose. Similarly, manufacturers are involved in the production of cellulose nanocrystals owing to their unique properties. In 2017, Borregaard, a key player in the nanocrystalline cellulose market invested a significantly to improve the production of nanocrystalline cellulose. CelluForce partnered with Fibria to manufacture nanocrystalline cellulose in 2016. The biodegradable nanocrystalline cellulose developed by Stora Enso is used for packaging dairy products. Manufacturers strive to expand their business into emerging economies in Asia Pacific.

Research on nanocrystalline cellulose has increased substantially in the last few years. Advancements in nanotechnology is a key factor driving the market. Key players operating in the global nanocrystalline cellulose market include Borregaard, UPM, CelluForce, American Process Inc, NIPPON PAPER INDUSTRIES CO.,LTD , RISE Innventia AB, Melodea Ltd, Oji Holdings Corporation, and Stora Enso. The nanocrystalline cellulose market is estimated to expand due to technological advancements. Rise in use of nanocrystalline cellulose biomedical, packaging, construction, and oil & gas industries is anticipated to drive the market.