Machine Builders Join Fight against COVID-19 to Produce PET Disinfectant Bottles

Companies in the PET preform machines market are joining the fight against the coronavirus (COVID-19) pandemic. Sidel— a global provider of PET solutions for liquid packaging, transformed its stretch-blow molding development center to a production of PET hand sanitizer bottles to support hospitals and pharmacies in France. Looking at such instances, other companies in the PET preform machines market are increasing efforts to distribute disinfectant bottles to healthcare facilities amidst the COVID-19 outbreak.

Due to the unprecedented demand for hand sanitizers and disinfectants in healthcare and pharmacies, PET manufacturers are increasing their production capabilities to reduce the shortage of medical products. These manufacturers are capitalizing on the COVID-19 crisis to boost their credibility by donating preforms and caps to make PET hand sanitizer bottles.

To understand how our report can bring difference to your business strategy, Ask for a brochure https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=77374

Computer Vision Technology Systems Provide Useful Data about PET Preform Machines

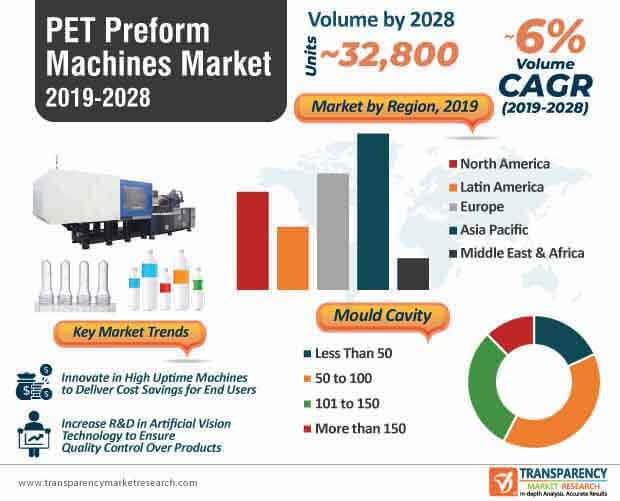

Ensuring total quality control over products is boosting the credibility of companies in the PET preform machines market. For instance, SACMI— a leading manufacturer of processing machines has gained efficacy in the artificial vision technology to deploy cavity recognition and grid inspection during production processes. Companies in the PET preform machines market are increasing efforts to develop proprietary technologies that ensure total quality control over products. Such introduction of new technologies is boosting the revenue for the market, which is estimated to reach a value of ~US$ 12 Bn by the end of 2028.

The computer vision technology is bringing about a change in the industry 4.0 revolution. Hence, companies in the market for PET preform machines are increasing their production capabilities to develop remote vision monitoring systems that allow complete inspection of products. They are increasing efforts to develop systems that provide a wealth of data about the machine status, counters, and alarms.

Full-hydraulic PET Preform Machines Bolster Production Rates for Clients in F&B Sector

Companies in the PET preform machines market are entering into strategic partnerships to accelerate the production of products. For instance, K-Tec— a provider of professional engineering services collaborated with Trexel Inc.— a specialist in placing microcellular bubbles inside injection-molded parts and Foboha GmbH, a tools manufacturer in Germany, to deploy fast cycle times and high-speed injection rates in developing PET preforms. There is the growing demand for high accuracy and high uptime PET preform machines that are capable of delivering exceptional precision and repeatability in production processes.

Novel injection molding machines that require minimum maintenance are gauging high demand in the PET preform machines market. Such innovative machines are boosting the expansion of the market for PET preform machines. Thus, equipment manufacturers are increasing the availability of machines with full hydraulic configurations to bolster production outputs. These novel machines are meeting requirements for customized solutions of clients in F&B and pharmaceutical sectors.

Special Recycling Lines Eliminate Challenges Associated with Effective PET Disposal

The circular economy is growing as a buzzword in the PET preform machines market. Hence, recyclers play a major role in successfully disposing off PET products and containers. However, technical limitations such as material losses after washing and grinding of PET bottles are affecting the process of recycling activities.

Recyclers lack the equipment to process PET fines into high-quality materials, thus resulting in inferior application of recycled PET. Thus, stringent regulations pertaining to plastic are slowing down the growth of the PET preform machines market. Hence, recyclers are increasing their R&D efforts to establish advanced recycling lines that maintain the special characteristics of PET fines. For instance, Starlinger— a supplier of machinery for producing woven plastic packaging, plastic recycling, and refinement is increasing efforts to develop special recycling lines for PET fines. As such, beverage producer Vöslauer Mineralwasser in Austria is making circular economy as part of its company philosophy and is increasing efforts to utilize 100% recycled raw materials. Thus, circular innovations are boosting the growth for the market for PET preform machines.

Stuck in a neck-to-neck competition with other brands? Request a custom report on PET Preform Machines Market https://www.transparencymarketresearch.com/sample/sample.php?flag=CR&rep_id=77374

PET Preform Machines Market: Overview

- According to Transparency Market Research’s latest report on the global PET preform machines market for the historical period of 2014 – 2019 and forecast period of 2020 – 2028, the market is anticipated to be driven by growing demand of PET based packaging containers in the food & beverages industry. The global PET preform machines market is expected to grow at a CAGR of 6% during the forecast period. Increasing demand for PET bottles for mineral water, energy drinks, and many other products packaging further boosting growth of PET preform machines market across the globe.

Need for Advanced Technologies for Increasing Production Efficiencies Driving PET Preform Machines Market

- Increasing production costs results in minimized profits. Nowadays, end users are planning to reduce production cost to achieve better profits in future. Cost of PET preform machines plays an important role in making strategic decisions.

- Also, it is a major influencing factor in the decision-making process to adopt advanced packaging technology

- Key players in PET preform machines market are focusing on developing such products, which will optimize the cost of the products with increasing production rate. PET preform machines are proving to be instrumental in decreasing costs, along with significant increment in the production capabilities through increased speed, reduction of bottlenecks, and capability to run 24/7. Industries, especially in some countries, are facing high labor costs and lack of skilled labor.

- Adoption of new technology-based PET preform machines eliminates the need to constantly find and train a new workforce, which allows employers to allocate more value-adding tasks to the available workforce, which in turn can reduce labor turnover through improved workplace conditions