Global Wire Feeder Systems Market– Introduction

A wire feeder system is used to maintain a feed of wire to join metals during welding and soldering. The wire feeder system is an advanced technological method composed of double driven wire feeding mechanism, print motor, rotatable torch holder, and wire spool shaft. Wire feeders have three main forms: push system, pull system, and push – pull system. In push system, the wire is pushed by the wire feed drive rolls to the welding torch, whereas in the pull system a set of wire is pulled from the roll of wire. In addition to it, the push–pull system is a combination of both the above system. Wire feeders are usually installed to help the machine perform an automatic welding and soldering job and enable automatic feeding of welding wires. With new technology innovation, the wire feeder is regarded as an automatic machine which uses a micro-motor to feed the wire.

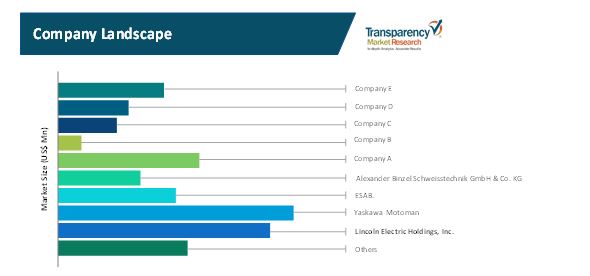

Global Wire Feeder Systems Market–Competition Landscape

Leading market players are focusing on the development of innovative wire feeder equipment to enhance operational efficiency across the world.

- In May 2019, Lincoln Electric Holdings, Inc. launched a new innovative wire feeder system called Activ8X, which is a semiautomatic and portable device with CrossLinc technology.

Lincoln Electric Holdings, Inc.

Founded in 1895, Lincoln Electric Holdings, Inc. is headquartered in Euclid, Ohio, the U.S. with approximately 10,000 employees. The company manufacturers different products such as arc welding equipment, welding consumables, welding products, oxy-fuel cutting and plasma equipment, and robotic welding systems. It has a worldwide network of sales offices and distributors in more than 160 countries. Furthermore, the company has its manufacturing units in North America, Latin America, Asia, and Middle East & Africa. Lincoln also operates joint ventures and manufacturing alliances in 19 countries across the world.

To Get Glimpse of what our report offers, Ask for a Report Brochure

Yaskawa Motoman

Established in 1989, Yaskawa Motoman is a leading industrial robotics company, having installed more than 15 million servos, 400,000 Motoman industrial robots, and 26 million inverter drives across the world. The company provides automation solutions and products for each industry and robotic application that includes arc welding, coating, assembly, dispensing, material cutting, material handling, packaging, material removal, palletizing, and spot welding throughout the world.

Some of the key players operating in the global wire feeder systems market are Yaskawa Motoman, Alexander Binzel Schweisstechnik GmbH & Co. KG, Lincoln Electric Holdings, Inc., Dr. Fritz Faulhaber GmbH & Co. KG, FengYuan Metallurgical Materials Co., Ltd., ESAB., NWorld s.r.l, DINSE G.m.b.H., Miller Electric, Guangzhou Huiyun Science & Technology Co., Ltd, Cigweld Pty Ltd, and ELMOTEC Antriebstechnik AG among others.

Global Wire Feeder Systems Market–Dynamics

Increase in manufacturing industries across the globe

The growing number of manufacturing industries across the globe is expected to boost the demand for wire feeders during the coming years. Wire feeder is an important device used for joining different types of metal through welding and soldering. Besides, with the use of wire feeder, raw material waste can be reduced, which is anticipated to fuel the growth of the wire feeder systems market globally. The manufacturing process not only increases profit margins of industries but also has a positive impact on resource regulation across the globe.

Rising demand for fabricated metal products and other metal-based products across the globe in different industries such as automotive, aerospace, electronics, and telecommunication is expected to boost the growth of the wire feeder systems market during the forecast period 2019- 2027. In industries such as electronics and telecommunication, where compressed size is an important factor, a wire feeder is used for manufacturing and metal joining processes. Furthermore, rise in demand for energy and power, where wire feeder is used to add filler metal during manufacturing of alloys, is also expected to boost the growth of the global wire feeder system market.