A roll forming machine is a rolling machine used for the bending of a long strip of metal sheets, which are usually coiled, into any desired profile (cross section). Roll forming machines are employed for generating constant-profile parts with long lengths. Roll forming machines are available in different shapes, sizes, number of spindles, and material thicknesses. Roll forming machines are energy efficient and they do not expend energy to heat the material. Roll forming machines are of various types such as single-duty roll forming machines, standardized roll forming machines, side-by-side roll forming machines, and double-headed roll forming machines.

To understand how our report can bring difference to your business strategy, Ask for a brochure

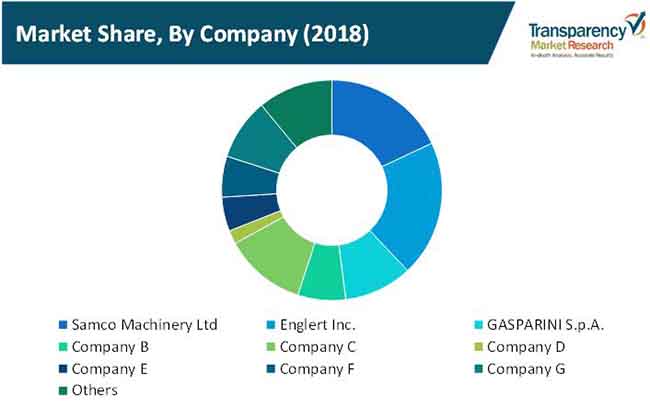

Global Roll Forming Machines Market: Competition Landscape

Englert Inc.

Established in 1966, Englert Inc. is situated in Perth Amboy, New Jersey, the U.S. The company designs, manufactures, and sells sheet metalwork products worldwide. The company provides several wall panels and metal roofing such as structural and architectural metal roof systems, wall panel systems, soffit systems, curved-panel metal roof systems, and retrofit framing products. The company also offers portable roll forming machines, roofing machines, gutter machines, and seamers.

Bradbury Co. Inc.

Established in 1959, Bradbury Co. Inc. is located in Moundridge, Kansas, the U.S. It develops, manufactures, and sells metal-processing equipment to customers across the globe. The company provides products such as roller levelers, coil-processing systems, metal-building systems, and steel-framing systems. It also offers decking products, appliances, railroads, and lighting products.

Samco Machinery Ltd

Established in 1972, Samco Machinery Ltd is located in Toronto, Canada. The company manufactures and designs roll forming machines and coil-processing equipment. The company also offers customized roll forming machines. The company serves various sectors such as automotive, decking & panels, power distribution, fencing, garage doors (including track and door skins), lighting, heating & air-conditioning, pre-engineered buildings (including siding, roofing, purlins, soffit, gutter, and cornerbead), shelving & racking, solar, steel stud framing, and window & door frames. Samco Machinery Ltd is an ISO 9001-certified company.

GASPARINI S.p.A.

Established in 1952, GASPARINI S.p.A. is located in Mirano, Italy. The company develops, manufactures, and designs metal forming machine tools. The company serves various sectors such as logistics, building & construction, power, and automotive. The company is certified with ISO 9001: 1994, ISO 9001: 2000, and SO 9001: 2008.

Other key players operating in the global roll forming machines market include Gurukrupa Industries, Form Process Engineering, Formtek Inc., Zeman Bauelemente Produktionsgesellschaft mbH, Howick Ltd, Metform international Ltd., AMS Controls, and Hayes International.

Stuck in a neck-to-neck competition with other brands? Request a custom report on “Roll Forming Machines Market”

Global Roll Forming Machines Market: Dynamics

Rapid Growth of Automotive Industry Driving Demand for Roll Forming Machines

Rapid growth of the automotive industry increases the production of automobiles, which augments the demand for roll forming machines. Roll forming machines are largely used in the automotive industry for making automotive parts such as bumpers, rocker panels, crash tubes, and door beams. Roll forming machines have ability to reduce the cost of operation and to form materials with high tensile strength. This is a major factor driving the demand for roll forming machines from automotive manufacturers. Furthermore, technological advancements, such as emergence of automated servo-electric roll forming machines, are also anticipated to fuel the market in the next few years. Advanced roll forming machines simplify the metal forming process and offer a high level of security.

Availability of Substitutes Hindering the Global Roll Forming Machines Market

Lack of trained workforce to perform troubleshooting and inspection to maximize the efficiency of roll forming machines is anticipated to adversely impact the demand for roll forming machines in the near future. Availability of substitutes, such as hot metal stamping machines, is another major factor anticipated to hinder the market during the forecast period. Hot metal stamping machines are popular in the manufacturing industry and they are also used to form 3D metal parts. The impact of this restraint on the global roll forming machines market is likely to be low in the next few years. We would also be providing PESTEL analysis for the market, which would help you to understand the overall macro-economic factors which have a strong impact on the market.

Read Our Latest Press Release: