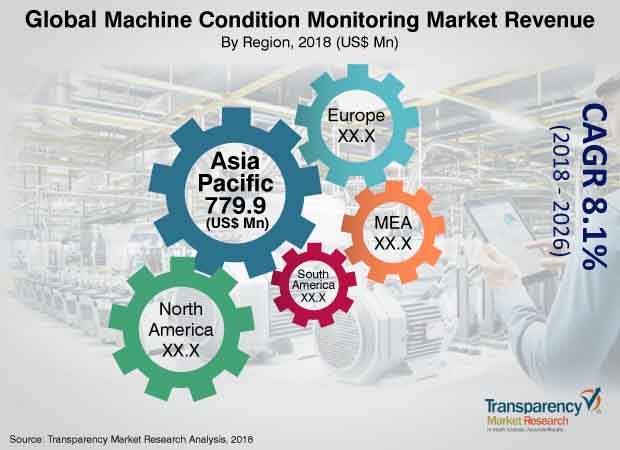

The global machine condition monitoring market was valued at US$ 2,212.3 Mn in 2017 and is anticipated to expand at a stable CAGR of 8.1% during the forecast period 2018 to 2026, according to a new report published by Transparency Market Research (TMR) titled ‘Machine condition monitoring Market– Global Industry Analysis, Size, Share, Growth, Trends, and Forecast, 2018–2026.’ Advantages offered by machine condition monitoring, increased adoption of vibration sensors, increase in equipment performance and productivity, rise in the adoption of machine condition monitoring in the automotive industry, rise in online machine monitoring, and increase in equipment performance and productivity have increased the penetration and growth of the global machine condition monitoring market. The market in Asia Pacific is likely to expand at a rapid CAGR of 8.6% due to numerous technological innovations in equipment condition monitoring systems.

Request a Sample – https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=12170

Rise in Demand for Online Monitoring to Drive Market Growth

Rise in predictive maintenance and need for accurate and time-efficient analyses of data have increased the demand for online machine condition monitoring globally. Manual collection of data can be performed only a limited number of times. On the other hand, online monitoring can collect large amounts of data at frequent points avoiding chances of human miscalculation in data collection.

Numerous players from North America are continuously involved in acquisitions in order to offer advanced machine condition monitoring to people who need the information on machine conditions in a timely manner. In September 2018, Azima DLI, a provider of predictive machine condition monitoring and analysis services, launched ‘WATCHMAN,’ its portable online intensive care condition monitoring system that can be quickly deployed by personnel in machines. Key trends prevalent in the global machine condition monitoring market are integrated machine condition monitoring system, technological advancements, cloud technology, wireless condition monitoring, and strategic collaborations.

Increasing Adoption of Vibration Monitoring is Expected to Drive Growth of the Machine Condition Monitoring Market

In terms of type, the market has been divided into thermography, vibration monitoring, lubrication oil monitoring, acoustic emission monitoring, ultrasound monitoring, corrosion monitoring, current signature monitoring, and others. The vibration monitoring segment is anticipated to dominate the market due to rise in adoption of vibration sensors for assessing equipment condition. Vibration monitoring provides analysis of the overall vibrations of components or machinery in order to observe abnormalities that may indicate faults. Furthermore, potential advantages of machine condition monitoring such as improved efficiency, increased machine availability and reliability, extended operational life, reduced costs, and improved safety are driving the global machine condition monitoring market. The vibration monitoring segment is anticipated to expand at a significant CAGR of 8.6 % during the forecast period. The lubrication oil monitoring segment is projected to expand at a significant CAGR over the forecast period, owing to the increasing use of lubrication oil as it plays an important role in early machine failure detection.