Companies Focus on Improving Weld Quality and Joining Processes

Laser plastic welding is extensively used across a host of industrial sectors, including medical, automotive, and electronic packaging. Advancements in textile joining, along with joining of different types of materials such as metal to plastics and more will continue to propel the demand for laser plastic welding across the world. Laser plastic welding is increasingly being deployed, particularly while developing products that are made of thermally sensitive materials. Laser plastic welding is also gaining considerable traction in wide-area lamination, as it offers precise patterns and increased complexity in joints that are made. Moreover, the demand for laser plastic welding is witnessing consistent growth, as it provides optimum strength and minimizes the cycle time in chemical bonding and mechanical joining applications.

Get Sample Copy:

https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=15332

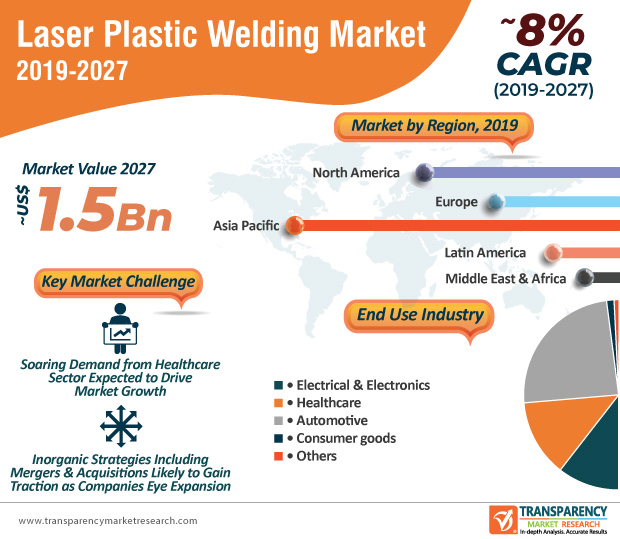

Some of the popular laser plastic welding techniques include ultrasonic vibration, hot plate, spin, radiofrequency, implant, and laser/infrared, among others. At present, product developers and companies operating in the current laser plastic welding market are increasingly focusing on opportunities in the healthcare sector. In addition, companies are also expected to focus on introducing new product designs in the current market landscape, and enhancing the overall efficacy and performance of their assembly/joining processes. Laser plastic welding has emerged as an ideal solution to create permanent bonds and applications that require a permanent seal or joint between different components. The global laser plastic welding market is on course to reach a market value of ~US$ 1.5 Bn by 2025.

Soaring Demand for Safe, Reliable, and Versatile Laser Plastic Welding in Healthcare

Although the cost of equipment for laser plastic welding is comparatively higher than other alternatives, its exceptional versatility makes it an ideal choice for applications in the medical sector. Laser plastic welding is used to assemble and join components made from a broad range of materials in different sizes and shapes. Moreover, as laser plastic welding requires negligible vibration and relative movement between two parts, it is capable of joining delicate components without inflicting damage. The adoption of laser plastic welding for the assembly of in vitro diagnostic (IVD) and micro-fluidic devices has witnessed consistent growth over the past decade and the trend is likely to continue over the stipulated time of the study. Companies operating in the laser plastic welding market are focusing on fulfilling the design requirements of their customers. The demand for laser plastic welding is on the rise as it offers exceptional welding quality, and improved aesthetics efficiently address the challenges put forward while joining complex geometries, versatility, etc.

While the healthcare sector will remain a prominent end-use industry in the laser plastic welding market, the automotive sector is expected to account for the highest market share. Advancements in laser plastic welding technologies have played a key role in improving the accuracy and weld quality of laser plastic welding due to which, conventional techniques in the laser plastic welding market are likely to be replaced during the forecast period.

Grab an exclusive PDF Brochure of this report:

https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=15332

Companies Rely on Inorganic Growth Strategies to Improve Market Share

Apart from focusing on improving the performance and quality of their welds, companies operating in the laser plastic welding market are also inclined toward expanding their market share by relying on inorganic growth strategies such as mergers & acquisitions. In addition, companies are also focusing on expanding their product portfolio to improve their position in the laser plastic welding market landscape. For instance, in June 2019, Dukane enhanced its laser plastic welding portfolio by acquiring the Blackhawk Technology Group. Dukane further announced that the acquisition of Blackhawk Technology would play an important role in improving its position in the market. The move will further strengthen the company’s product portfolio, which finds application in a host of industrial sectors.

While inorganic growth strategies are likely to gain considerable momentum, multiple companies are also expected to focus on introducing cutting-edge technologies to improve the quality of their laser plastic welds. For instance, in July 2017, Trumpf GmbH announced that the company is integrating EHLA– a new technology that is faster and offers greater efficiency than conventional laser deposition welding.

Request For Customization:

https://www.transparencymarketresearch.com/sample/sample.php?flag=CR&rep_id=15332

Analysts’ Viewpoint

The global laser plastic welding market is expected to grow at an impressive CAGR of 8.4% during the forecast period. The market growth is driven by a host of factors, including soaring demand from end-use industries, progress in laser technology, dwindling prices of laser technology, exceptional versatility, and progress in technology. Companies operating in the current landscape should focus on expanding their product portfolio, integrate new technologies, and enhance the quality of their products. The automotive and healthcare sectors will present players in the laser plastic welding market with plenty of opportunities as the demand for improved joining and assembly technologies is anticipated to move in the upward trajectory, particularly from these two sectors.

Laser Plastic Welding Market: Overview

- According to Transparency Market Research’s latest market report on the laser plastic welding market for the historical period of 2016-2019 and forecast period of 2020-2025, rapid growth in the automotive industry is anticipated to bolster laser plastic welding market growth. Globally, the laser plastic welding market is estimated at ~US$ 950 Mn in 2019, and is projected to register a CAGR of 8.4% during the forecast period of 2020-2025.

Technological Advancement in Laser Plastic Welding Machines Bolstering Demand

- Technological advancements in laser plastic welding systems is one of the crucial factors that attract a substantial portion of the end-use industry players. Leading manufacturers operating in the laser plastic welding market are putting constant efforts to design and manufacturer high precision laser plastic welding machines. Key manufactures are investing significantly in research and development to develop lasers systems with a narrow laser beam, as it facilitates the overall welding process. For instance, on October 2017, LPKF Laser & Electronics AG has introduced a powerful processing unit, PU-W, developed specifically for plastic welding, with continuously varying laser spot diameter between 2.2 to 4mm.

- In addition to these, on June 2017, Trumpf is another manufacturer operating in the laser plastic welding market has launched its TruDiode 4001.5 machine at LASER World of Photonics, Munich. This machine is based on patented technology of Trumpf, DWM (Dense Wavelength Multiplexing). This technology greatly reduces the size of the laser systems for processing of larger and heavier components.

Rapidly Dropping Prices for Lasers and Laser Systems Accelerates Market Growth

- Over the past few years, the pricing for diode and Nd:YAG lasers has dropped significantly. Laser sources with the power of around 100W, which used to cost significantly a decade ago are now available in affordable pricing. This has resulted in a decline in the prices of laser systems. The manufacturers of almost all the industries deal with plastic materials due to its various advantages over metals, such as much lower weight and ease in processing. This has encouraged a large number of small manufacturers to emerge in the market and compete in the manufacturing of plastic products. Until the last few years, only some of the large manufacturers with high production output were capable of affording the laser technology for material processing.

- Drop in prices of laser technology and enhanced availability, along with high applicability has encouraged moderate and small manufacturers to adopt the laser plastic welding technology. The decline in the prices of the laser technology, accompanied by globally increasing manufacturing output, is anticipated to drive the laser plastic welding market during the forecast period.

Read TMR Research Methodology @:

https://www.transparencymarketresearch.com/methodology.html

Requirement of Compatible Combination of Materials Restricts Laser Plastic Welding Market Growth

- The laser plastic welding creates high precision welds with a high-quality finish and thus, seems to enhance the ease in plastic processing. On the other hand, the application of laser technology is dependent on the condition of materials to be weld. Various factors such as thickness of the upper material through which the laser beam will pass, surface roughness of the surfaces to be weld, color of the two materials, material used, etc.

- The laser plastic welding is not a big challenge when one of the materials is transparent and the other is black. The difficulty level increases with combinations such as black on black, colored on black, two different colored materials, two transparent materials and most difficult with a pair of two white materials.

- Moreover, physical properties such as roughness play a crucial role in the quality of weld as with the minute change in the distance of the absorbent surface from the laser source, the diameter of the laser spot changes, resulting in change into energy density and thus non-uniform weld. Thus, the low surface finish of the surface results in highly non-uniform weld. Thus, highly specific requirements of laser plastic welding pose a restraint on the laser plastic welding market.

Healthcare Industry to Offer Gratifying Opportunities to Manufacturers

- The demand for a variety of plastic medical devices across continents has witnessed a sharp rise in recent years. This significant rise in demand for plastic medical devices is majorly driven by improving healthcare facilities and rapidly rising healthcare expenditure by individuals. Laser plastic welding machines are predominantly used in the healthcare industry, especially medical device industry, as these devices require clean joints. Furthermore, manufacturers of medical devices preferring laser plastic welding over traditional welding techniques as it provides faultless and excellent surface finishing.

- Moreover, the surgical nature of laser plastic welding makes it well suited to handle the delicate and precision joining. Owing to such factors, the demand for laser plastic welding systems across the globe is projected to increase during the forecast period. In addition to this, striking penetration of healthcare industry in key regions such as North America, Europe, and Asia Pacific regions is providing gratifying opportunities to laser plastic welding machines manufacturers to maximize its financial revenue.

Read Our Latest Press Release:

About Us

Transparency Market Research is a next-generation market intelligence provider, offering fact-based solutions to business leaders, consultants, and strategy professionals.

Our reports are single-point solutions for businesses to grow, evolve, and mature. Our real-time data collection methods along with ability to track more than one million high growth niche products are aligned with your aims. The detailed and proprietary statistical models used by our analysts offer insights for making right decision in the shortest span of time. For organizations that require specific but comprehensive information we offer customized solutions through ad-hoc reports. These requests are delivered with the perfect combination of right sense of fact-oriented problem solving methodologies and leveraging existing data repositories.

Contact

Transparency Market Research State Tower,

90 State Street,

Suite 700,

Albany NY – 12207

United States

USA – Canada Toll Free: 866-552-3453