Robotics is a branch of engineering that deals with the development, design, construction, and operating of a robot. Robotics comprises electrical, mechanical, and computer engineering. Robotics is widely categorized into service robots and industrial robots. Service robots are further classified into professional robots, personal robots, and domestic robots. Application of the robotics technology in a wide range of production processes across the globe has led to rise in the adoption of the technology at a rapid pace. In the last few years, robots are also being utilized in the construction industry. The construction robots market is projected to expand at a CAGR of 10.4% during the forecast period and reach value of US$ 470.61 Mn by 2026.

The construction industry is one of the least automated industries, as it features manual-intensive labor as a prime source of production. Whether it is new commercial construction, demolition, or renovation, robots can play an important role in a building’s life cycle. Being a highly unautomated industry, the construction industry can witness a major impact with the emergence of construction robots. As construction companies are looking for automation of more and more tasks in order to increase efficiency and productivity, the demand for construction robots is likely to increase gradually in the near future.

Request for a sample:

https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=56457

In addition to this, implementation of robotics in the construction industry eliminates human issues such as laziness, mistakes, damage, conflicts with co-workers, and the need for security and health insurance. Specialized robots can also work in dark, small, airless spaces that are dangerous for humans, or on the facades of tall buildings, without any unsteadiness. Moreover, robots can function 24×7, in a wide range of conditions. They eradicate potential risks arising from lawsuits, accidents, etc., as there are no workers onsite.

Employing robots on construction sites might have been considered unfeasible in the past. Several construction specialists are still viciously opposing the use of robots and they are worried of losing their jobs. In contrast, excessively high costs of manufacturing, constructing, and using robots onsite in comparison to costs of employing laborers is a major concern of several other construction specialists advocating the innovative idea. Hence, hiring a robot to work onsite is not an imminent threat to workers. In February 2018, Construction Robotics Company announced the launch of its new product ‘SAM 100,’ which can place between 300 and 400 bricks an hour, as against a human worker who can lay only around 60–75 bricks in an hour. This can give idea about benefits of using construction robots onsite.

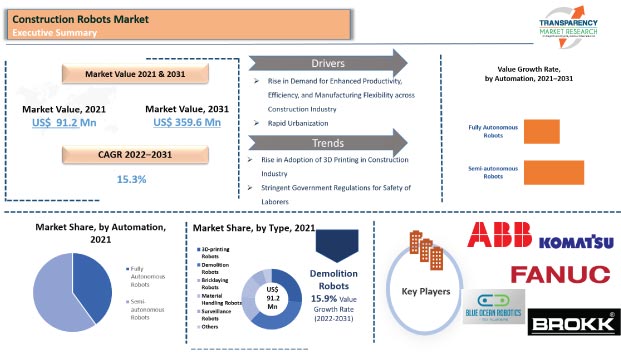

Attracted by anticipated growth of the global market and underlying latent demand, several players are expanding their business through strategic mergers and acquisitions and partnerships. For instance, in February 2017, Brokk AB, a leading manufacturer of remote-controlled demolition machines, acquired Aquajet Systems AB, a global supplier of hydrodemolition robots. The acquisition expands application solutions offered by Brokk in the construction & demolition industry. Some of the prominent players operating in the global construction robots market are Brokk AB, TopTec Spezialmaschinen GmbH, Construction Robotics, Komatsu, Ekso Bionics, Fujita, Fastbrick Robotics, Autonomous Solutions, Giant Hydraulic Tech, Yingchuang Building Technique Co. (WinSun), Alpine Sales and Rental, and Beijing Borui Intelligent Control Technology.

While construction is considered the most largest as well as oldest economic sectors in the globe, the sector has been experiencing lack of research and development activities. With the introduction of construction robots, there are remarkable advancements in many activities performed in this sector. The global construction robots market is expected to gather promising growth opportunities in the forthcoming years. This growth is attributed to growing technological advancement in worldwide construction industry.

Construction robots refer to the robots used in the construction sector for performing numerous activities that are more dangerous, more monotonous, and more repetitive. Thus, these robots can be employed for performing almost 80% of construction activities. While almost all industrial sectors across the world are growing focus toward automating majority of their work, introduction of robotics in construction activities has changed this sector to large extent.

Ask for brochure:

https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=56457

Many companies in the construction sector are growing focus toward use of robotics in their projects. One of the key advantages of these initiatives is the ability of construction robots to eliminate various human issues including errors, laziness, conflicts with co-workers, damage, and the requirement of health insurance and security. Owing to these advantages, the global construction robots market is estimated to experience decent sales avenues in the future period.

Several specialized robots hold an ability to work in adverse conditions such as dark, tiny, and airless spaces that can be harmful for humans’ health. In addition to this, these robots can be employed to perform work on the facades of lofty buildings, without any shakiness. Apart from this, construction robots can perform work without break for about 24 hours a day. With no workers onsite, these robots eliminate possible risks that can occur due to accidents and lawsuits. On the back of all these benefits, the global construction robots market is likely to grow at moderate pace in the years to come.

Read TMR Research Methodology at: https://www.transparencymarketresearch.com/methodology.html

Read Our Latest Press Release: