The demand for built-in heaters in production systems, liquid warming resources, surface heat applications and similar continues to increase and more and more applications in automated assemblies or production facilities continue to push boundaries of what’s possible. As manufacturing continues to become more and more specialized, particularly with custom work, the need to match heating elements to various channels becomes more and more pronounced.

Problems With Non-Specific Applications

Oftentimes, production facilities and their engineers will frequently develop a make-work heating system from generic sources and equipment. The problems with using these kinds of one-off assemblies, however, are multiple. First, there’s safety. Because many one-off generic systems are a component of parts versus a complete assembly, they likely will fail a comprehensive operational safety test because the parts themselves were never tested in tandem with each other in many cases. Second, not all the generic heating components available are intended to work as applied in a given situation. That can result in a variety of issues ranging from system compatibility and interference problems to inefficiencies and cost loss on wasted energy consumption. Third, training is ad hoc and walks out the door as soon as the person who knows how to run the generic system leaves. That can put a plant in a pinch quick.

Matching the Right Equipment to the Need

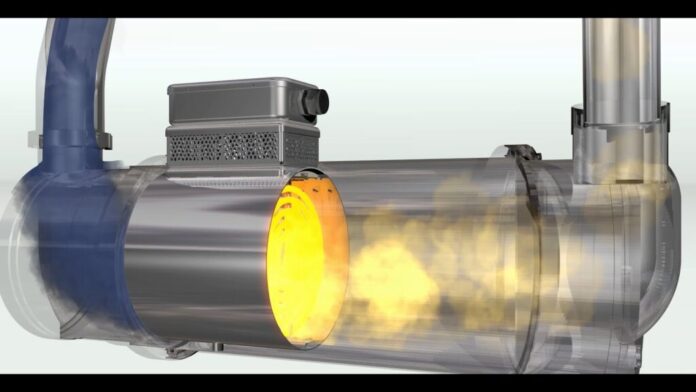

With Watlow Heaters, a system manager works with heating elements that are specifically designed for the application they are used. They have met safety standards as well as operational performance expectations, and Watlow provides regular support and reference for all of its heater products so there is never a loss of knowledge during a role transfer situation. Secondly, Watlow Heater come in a variety of choices and applications, so there will be very few situations where a Watlow product can’t be matched correctly to the production demand needed. Finally, plant and manufacturing systems stop bleeding inefficiencies and wasted energy, realizing real savings to the operational bottom line, which is always a good thing.

Overall, Watlow Heaters are just a better way to go versus trying to rely on a generic, cobbled-together alternative. To find out more, give our expert staff at Seagate Controls a call or email, and we can work with you to match an available Watlow Heater product to your needs correctly from the start.