The use of pulp in a multitude of industries such as wood and paper manufacturing, packaging, and food/beverages has played a vital role in market growth. Various types of pulp can be obtained from natural sources such as trees, bamboo, and teak. The use of pulp as an intermediary material for manufacturing several finished goods or items has played a defining role in market growth and maturity. Pulp obtained from old rags, fiber crops, and cellulose fibers has gained popularity in recent times. The growing relevance of pulp in the field of paper manufacturing has given a thrust to market growth.

- As the energy sector focuses on the use of recyclable and biodegradable materials, the demand for wood- and paper-based pulp has increased. Polyethene bags have been replaced by paper bags in recent times.

- In addition to this, harvesting of various trees that are viable sources of pulp have also attracted the attention of the manufacturers. The total volume of revenues within the global pulp market is set to increase in the years to follow.

- Pulping technologies have attracted the eyes of several investors, and this trend shall also play a crucial role in market maturity over the next decade.

The demand within the global pulp market is set to rise on account of advancements in paper manufacturing. The presence of a seamless industry for paper manufacturing has enabled several new entities to enter the industry. The pulp market spans into a multitude of industries, including textiles, paper, food and beverages, and automobiles. The use of wooden pulp in the field of furniture manufacturing, and for producing soft pieces used in the residential sector, has given an impetus to market growth. There is growing relevance of chemical research across several industries, and development of usable pulp is also an outcome of improved research. The revenues index of the global pulp market is expected to improve over the course of the next decade.

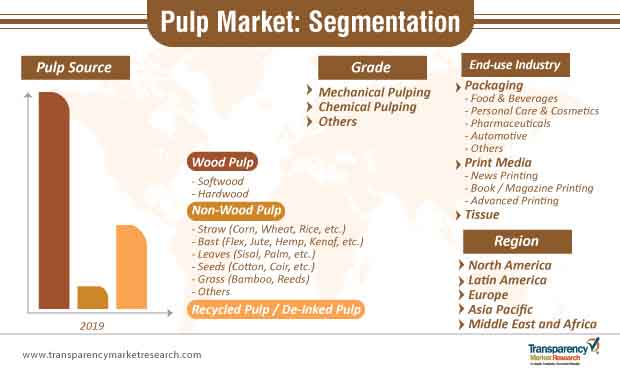

- The value of the global pulp market has perpetually increased over the past decade. Pulp obtained from bamboo, jute, and grass is extensively used across a multitude of industries. In addition to this, the emergence of dedicated industries to manufacture wood pulp is an important dynamic of market growth. The next decade is slated to witness increased popularity of pulp made from straw, wheat, corn, and rice. This factor shall directly aid the growth of the global food and beverages industry in the times to follow. Cotton pulp is also in great demand across several industries, and this is an important dynamic of market growth.

- The textile industry has increased its research budget over the past few years. This trend shall result in easier procurement and manufacturing jute and flex pulp. Furthermore, hemp pulp is also gaining popularity across the textiles sector. The automobile industry has lately emerged as a prominent consumer of pulp in recent times. As end-use industries reconcile their manufacturing dynamics, the total volume of revenues within the global pulp market is set to multiply.

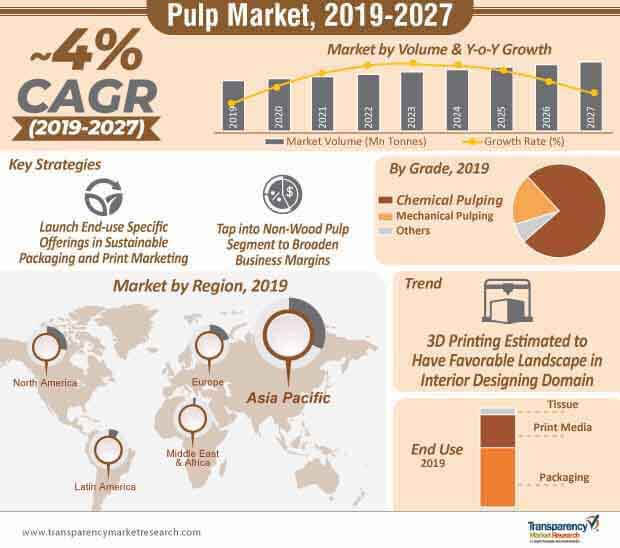

Pulp Market: Golden Age for 3D Printing Creating New Opportunities for Manufacturers

Manufacturers in the pulp market have been struggling to compete with the advantageous attributes of plastic in commercial and domestic commodities since the past few years. However, strict regulations by governments to impose a ban on plastic and its applications in various domains have created opportunity windows for players of the pulp market across various other industries.

Stakeholders are finding new alternatives for plastic, with raw materials such as wood, metal, plastic, textiles, and ceramics. These alternative materials are helping manufacturers in prototyping the attributes of plastic in commercial and domestic commodities. One such innovation is paper pulp 3D (3 Dimensional) printers that extrude the paper waste with a natural binder, which helps in creating aesthetically-pleasing 3D models.

Planning to lay down future strategy? Perfect your plan with our report brochure here

Paper pulp 3D printers can be used for the designing of various printed objects, and players of the pulp market are using this technique to emphasize a tactile experience of the objects with bold lines and distinctive shapes. The process of reducing wood or paper fibers into individual cellulose fibers attributes to the strong and durable quality of the printed paper. Thus, the unique look of the print gives the printed model an exclusive personality for consumers who are constantly in search of something very uncommon.

Beer Holthuis, a product designer from the Netherlands operating in the pulp market, channelized his interest for 3D modeling and additive manufacturing, and announced the launch of the one-of-its-kind paper pulp printer that sustainably prints 3D models from paper waste. Thus, this low cost alternative with its sustainable aspect has a bright potential for designers and manufacturers in the future.

Another trend that is catching the attention of pulp manufacturers is the use of 3D printing in the furniture industry and interior designing sector. 3D printing material is a valuable renewable resource that stores carbon and can be easily recycled. As such, wood-based waste can be up-cycled into wood polymer composite and can be used to make furniture. Likewise, researchers at the Michigan Technological University used furniture feedstock as a 3D printer filament to produce furniture components.

Print Marketing and Packaging Capture the Attention of Pulp Manufacturers

The popular belief that the digitization of business operations in various industry domains is going to make paper and forest-product industries shut down has been stressing pulp manufacturers since the past few years. However, the reality does not seem to be so superficial, as paper and print companies still hold a major stake of their target customers who prefer the extensive exposure that paper and print commodities provide, such as magazines, books, and newspapers.

The global pulp market is estimated to be valued at ~US$ 237 billion by the end of 2019, and is anticipated to reach ~US$ 333 billion by 2027. Although the pulp market is growing at moderate speed, the packaging industry is expected to grow all over the world, thereby influencing the important trends in the pulp market in the coming years.

Increasing demand for lightweight paper packaging has been fostering the growth of the pulp market, resulting in the growing trend of strategic collaborations among pulp manufacturers and stakeholders in the packaging industry. For instance, Mondi Group — a leading global packaging and paper company, announced the acquisition of Powerflute Group Holdings, which is a division of Nordic Packaging and Container Holdings. This strategic partnership supports the business plan by investing in high quality packaging and paper assets, which will aid Mondi Group in widening its containerboard product fleet and create more geographical expansion opportunities in other potential regions.

Apart from this, numerous other labs and development centers are increasing their research & development initiatives to provide consumers with sustainable and low-cost alternatives in softwood product offerings and its components.

Want to know the obstructions to your company’s growth in future? Request a PDF sample here

Manufacturers’ Move towards Sustainable Raw Materials to Give Rise to Non-wood Pulp Products

Pulp manufacturers are capitalizing on environmentally-sustainable ways to revolutionize pulp production with the help of non-wood pulp substitutes, such as wheat straw, to produce commodities such as paper towels, packaging, facial tissues, and molded fiber for single-use plates and cups, alongside de-icing and dust-abatement agents. These applications of non-wood pulp are aiding manufacturers in producing high-quality, commodity, and specialty straw pulp, which is directly offered for sale to paper and packaging manufacturers as an alternative to wood-based pulp materials.

Thereby, though wood pulp accounts for ~three-fourth revenue share of the pulp market, the demand for non-wood pulp and recycled pulp is expected to increase at a faster rate in the coming years. With the rising demand for sustainable non-wood fiber in North America, Columbia Pulp — a leading global pulp manufacturer, collaborated with Allnorth — another leader in multidisciplinary engineering and construction services consulting, to facilitate the pulp market in North America with quality-specific non-wood fiber-based pulp products that are either as good as or even better than hardwood and recycled pulp.

This collaboration has also helped improve the air quality at one of the densest wheat producing regions of North America, Snake River, in Washington State which was otherwise under the predicament of burning down huge volumes of wheat straw, and has created employment opportunities for farmers.

Read Latest Press Release From TMR: