Stakeholders Invest in Advanced Labelling Systems to Increase Traffic to Websites

Various factors have catalyzed innovations in labelling machines. With growing awareness about the hazardous effects of plastic on the environment, companies are increasing research to remove all plastic from their label product packaging. As such, labelling, decorating, and coding machines product segment is estimated to lead the packaging machinery market, in terms of volume. Moreover, the global packaging machinery market is projected to reach an output of ~2,573,400 units by 2026. Hence, manufacturers in the market for packaging machinery are innovating in peel and reveal labels.

Companies in the packaging machinery market are increasing their efficacy in novel technologies that can insert unique codes on the inside page to help stakeholders drive traffic to their website. On the other hand, embossed and laminated labels are being created on different substrates. Stakeholders in various end markets are investing in automatic labelling systems to cater to Radio Frequency Identification (RFID) and barcode scanning applications.

Get Sample Copy:

https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=3076

Cutting-edge Filling & Dosing Machines save Time in Sterile Environments

Innovative packaging machinery has helped manufacturers to save cost on time and manpower. Companies in the packaging machinery market are introducing latest technologies for sterile filling. For instance, special manufacturer of primary packaging Lameplast, presented their new machinery Pentafill A25- an automatic sealing and filling machine designed to function in sterile environments.-Dedicated and appealing products require innovations in filling and dosing machines. As such, the filling & dosing machines product segment of the packaging machinery market is expected to account for the highest revenue by the end of 2026. Hence, manufacturers are increasing R&D in filling & dosing machines to diversify their packaging services.

Currently, there is a growing demand for single-dose unit packaging in the market for packaging machinery. Companies are increasing research to induce versatility in these novel filling & dosing machines. Stakeholders in various end markets are benefitting from the advantages of compact machines that fit in small rooms and are easy to maintain.

Compact Liquid Unit-dosing Cup Machines Overcome Limitations of Floorspace and Accuracy

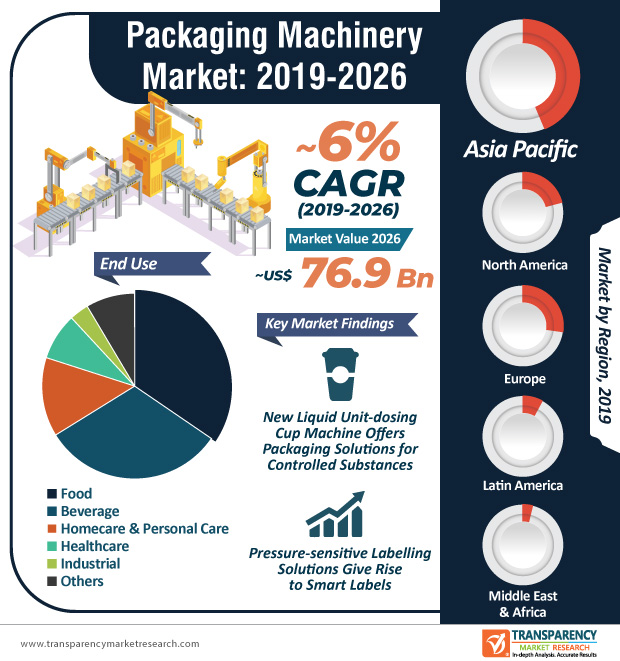

The packaging machinery market is expected to grow at a CAGR of ~6% during the forecast period. Technological innovations are likely to boost market growth. However, challenges of floorspace and accuracy of machines act as a barrier for packaging companies, especially in the pharmaceutical landscape. Hence, companies are introducing new liquid unit-dosing cup machines that ensure accuracy in packaging of controlled substance without sacrificing the floorspace. These novel machines are being manufactured to target small pharmaceutical manufacturers and contract development & manufacturing organizations (CDMOs).

Since the beverage end use segment is anticipated to account for a significant share of the packaging machinery market, companies are increasing their production capacities to manufacture coffee capsule packaging machine. They are aiming to transform the operational procedures by introducing virtual operation in the machines. Multilane sachet packaging systems are growing popular in the market for packaging machinery. Companies are increasing the availability of end-to-end automated packaging solutions using the vertical form-fill-seal technology. On the basis of this technology, companies in the market for packaging machinery are making it possible to group and package sachets in tamper evident cartons.

Request For Customization:

https://www.transparencymarketresearch.com/sample/sample.php?flag=CR&rep_id=3076

Technological Advancements Lead to Introduction of Cost-efficient Automated Packaging Solutions

The ever-growing packaging machinery market is undergoing a change with the introduction of software-controlled pick & place case packing solutions. For instance, Blueprint Automation-a provider of innovative packaging automation solutions, has gained expertise in vision-guided robotic case and tray loading. Companies in the packaging machinery market are leveraging these robotic machines with cameras that are used as sensors to handle packages of any dimension. This attribute of robotic machines has helped stakeholders in the value chain to reach high production levels. Thus, stakeholders are receiving value for money, as these automatic systems are highly adaptive in functionality.

Likewise, companies in the market for packaging machinery are increasing R&D in cost-efficient automated box packaging technology. Multiple functions in a single system, such as opening, folding the flaps, and sealing in one go are gaining the attention of stakeholders in various end markets. This novel technology is acquiring popularity, since it helps to save secondary packaging time and efforts, especially for shipping large volume of goods.

Grab an exclusive PDF Brochure of this report:

https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=3076

Packaging Machinery Market: Overview

According to Transparency Market Research’s latest report on the packaging machinery market for the historical period of 2013-2018 and forecast period of 2019-2026, demand for machinery automation and renovation is anticipated to boost demand for packaging machinery services. Globally, the packaging machinery market was valued at ~US$ 49 Bn in 2018 and is anticipated to witness a CAGR of ~6% during the forecast period of 2019-2026.

Government Initiatives to Boost Growth of Global Manufacturing Sector

- The manufacturing sector has witnessed substantial growth in the recent years, particularly in the developing economies of Asia Pacific and Latin America such as Brazil, China, India, and ASEAN. Governments in these countries are widely supporting local manufacturing through various campaigns.

- The Indian government launched a new “Make-in-India” campaign to support new entrepreneurs in the country by offering tax incentives and aid in capital investment.

- Made-in-China 2025 is a 10 year industrial development plan of China with an aim to increase Chinese domestic content of core materials to 40% by 2020 and 70% by 2025. It is clear that growth in the manufacturing sector will further boost the demand for packaging machinery in these countries.

- However, this trend is not limited to only developing countries. consumption of packaging machineries is also increasing at a considerable pace in developed countries such as Italy, Germany, and the U.S. The Italian domestic packaging machinery market is expected to witness a CAGR of 5.6% during 2018-2026, on the back of increasing demand for highly advanced packaging machinery from the manufacturing sector.

Use of Advanced Packaging Technologies Increasing Efficiency

- Companies with profitable businesses aim to reduce costs to achieve a better bottom line. Cost of packaging machinery and adopting advanced packaging technology plays an important role in making strategic decisions.

- Major manufacturers in the packaging machinery market strive to launch products that help companies to reduce labor charges and gain greater production outputs in lesser time. These solutions are proving to be helpful in decreasing costs along with significant increment in the production capabilities through increased speed, reduction of bottle necks, and capability to run continuously.

- Adoption of such packaging machinery removes the requirement to frequently find and train a new labour force, which lets companies to assign more value adding responsibilities to available workforce, which in turn can reduce labor turnover through improved workplace conditions.

- Packaging manufacturers can gain benefits by adopting these advanced packaging machinery technologies such as FFS (Form-Fill-Seal), LDC (Labelling-Decorating-Coding) and others.

Asia Pacific to Offer Substantial Growth Opportunities

- The packaging industry in the Asia Pacific region is expected to offer lucrative growth opportunities during the forecast period, supported by the substantial growth in consumption of packaging across each major country in the region

- Manufacturers located in Germany, Italy, and the U.S. can focus on exporting their packaging machinery offerings to developing countries such as India and China to cater to the demand generated through ever-increasing consumption and orders for native manufacturing. Moreover, some of the companies believe that the packaging machinery manufacturers present in developed countries such as Germany and Italy offer better and advanced technology products with superior quality.

- However, it is very necessary for multinational packaging machinery companies to compete in the high growth markets such as China to establish their presence. Multinational companies are targeting this region through various expansion activities such as mergers with prominent regional players or by acquiring smaller players.

- This market extension strategy is expected to play a significant role in acquiring new customers in the global packaging machinery market

High Import Duties and Cost of Machinery Restraining Demand

- One of the major trends observed in the packaging machinery market is the global export of packaging machinery from five major countries. Germany, Italy, the U.S., China, and Japan dominate the global packaging machinery market in terms of export and production.

- All of these countries generate significant amount of revenues through the sales of packaging machinery globally. Germany and Italy are known for supplying highly advanced packaging machinery in the global market. However, China has secured a strong position in the market, attributable to its export of low-cost machinery with comparable production outputs.

- Majority of the countries in the world do not have a strong manufacturing base for the production of packaging machinery. Therefore, end-use companies present in these countries opt for import of machines from the aforementioned five countries.

- However, import has become the one of the major issues for these companies due to high custom duties and various taxes imposed on packaging machinery imported from other countries.

- In India, imported packaging machinery costs approximately 30% more than the actual cost of the machinery, thereby making the customer pay 30% more of the price for similar machinery purchased in the country of origin.

Packaging Machinery Market: Competition Landscape

- The market for packaging machinery is highly fragmented. Service providers in the packaging machinery market focus on acquisitions and mergers to expand their presence across the globe.

- Some key players operating in the global packaging machinery market are

- Robert Bosch GmbH

- I.M.A. Industria Macchine Automatiche SpA

- Tetra Pak International S.A.

- Coesia S.p.A.

- Marchesini Group S.p.A.

- OPTIMA Packaging Group GmbH

- Omori Machinery Co. Ltd.

- ProMach, Inc.

- Herma GmbH

- Videojet Technologies, Inc.

- Muller Load Containment Solutions

- Premier Tech Chronos Ltd.

- Ishida Co. Ltd.

- PFM Group

- GEA Group Aktiengesellschaft

- Sidel S.A.

Read Our Latest Press Release:

About Us

Transparency Market Research is a next-generation market intelligence provider, offering fact-based solutions to business leaders, consultants, and strategy professionals.

Our reports are single-point solutions for businesses to grow, evolve, and mature. Our real-time data collection methods along with ability to track more than one million high growth niche products are aligned with your aims. The detailed and proprietary statistical models used by our analysts offer insights for making right decision in the shortest span of time. For organizations that require specific but comprehensive information we offer customized solutions through ad-hoc reports. These requests are delivered with the perfect combination of right sense of fact-oriented problem solving methodologies and leveraging existing data repositories.

Contact

Transparency Market Research State Tower,

90 State Street,

Suite 700,

Albany NY – 12207

United States

USA – Canada Toll Free: 866-552-3453