Adoption in Liquid Scavenging Processes to Foster Growth of N-MDEA Market

The industrial sphere has witnessed significant developments in past two decades wherein the consumption of fossil fuels, including oil, natural gas, and coal has risen exponentially. However, the increase in the consumption of these fuels has led to significant environmental degradation due to the high amounts of CO2 released in the atmosphere. Despite considerable efforts being made to minimize CO2 emissions, it continues to pose a constant challenge in several countries worldwide. Within the N-MDEA market, stakeholders are focusing on restricting the environmental impact of gas treatment processes by investing in research and development.

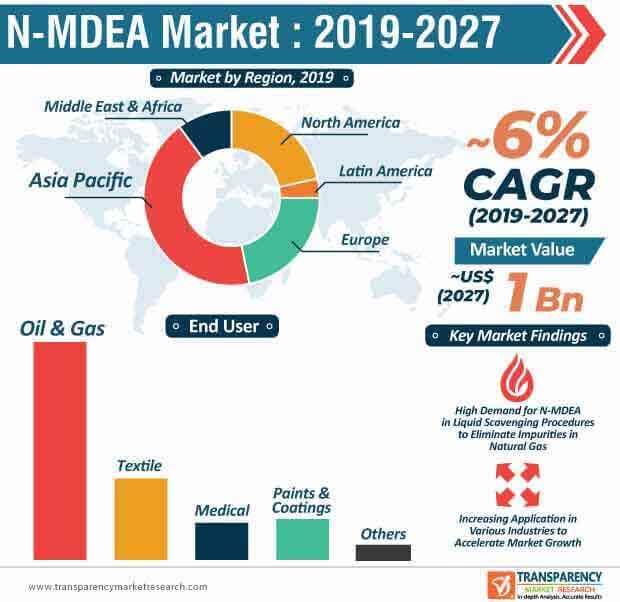

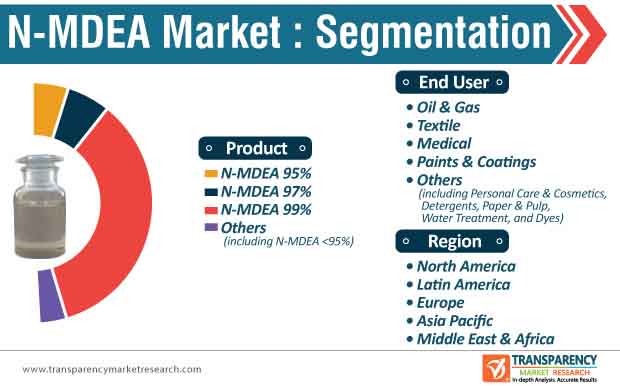

Gas treatment technologies have evolved at a rapid pace and at present, natural gas has garnered the reputation of being one of the cleanest fossil fuels. However, liquid scavenging is required to eliminate impurities, including H2S and CO2. Typically, alkanolamines such as N-MDEA are extensively used in the regenerative H2S removal processes, which, in turn, has increased the demand for N-MDEA across the world. In the current scenario, N-MDEA is widely used across a range of industry verticals such as oil & gas, textile, paints & coatings, and medical. Growing applications of N-MDEA in these end-use industries are expected to drive the N-MDEA market, which is expected to reach a value of ~US$ 1 Bn by 2027.

To gauge the scope of customization in our reports Ask for a Sample

Oil & Gas Sector to Offer Lucrative Opportunities in N-MDEA Market

The demand and consumption of natural gas in different industrial verticals is witnessing a steady growth worldwide, catering to ~23% world energy requirement in 2017. The growing adoption of natural gas can be attributed to its economic benefits and energy-efficiency in comparison with crude oil. Methane is an integral component of natural gas. However, it constitutes several impurities, including acid gases and other hydrocarbons. These impurities hamper the gas energy value and also lead to significant corrosion in the pipeline. It is thus, imperative to eliminate these impurities, and liquid scavenging procedures with N-MDEA are employed for the regenerative removal of H2S.

REQUEST FOR COVID19 IMPACT ANALYSIS –

https://www.transparencymarketresearch.com/sample/sample.php?flag=covid19&rep_id=41669

The ascending demand for N-MDEA within the oil & gas sector is likely to provide an impetus for growth of the N-MDEA market during the forecast period (2019-2027). The oil & gas sector is projected to account for ~55% share of the N-MDEA market by 2027, with an estimated volume consumption of ~252-kilo tons. Despite the growing demand for N-MDEA from other industrial sectors, including textile and medical, oil & gas industries will remain the most prominent end user during the assessment period.

Get an idea about the offerings of our report from Report Brochure

Onset of Energy-efficient Acid Gas Removal Systems to Hamper N-MDEA Market Growth

The adoption of chemical absorption technology within acid gas removal systems has been a common practice for several decades. However, concerns over this energy-intensive process encouraged participants in the oil & gas sector to find energy-efficient acid gas removal systems. In the current scenario, a majority of acid gas removal systems rely on desorption/absorption process, which utilizes a solution of water and N-MDEA. However, these acid gas removal systems are marred with several shortcomings, of which, the high amount of energy required to regenerate rich amines has gained significant attention.

The energy-intensive process accounts for ~60-70% of the overall operating costs in acid gas removal systems. In their quest to address this problem of high regeneration consumption, several attempts were made to minimize energy consumption and improve the overall performance of sour gas loading. Thus, companies within the oil & gas sector are leaning toward other alternatives, including co-process produced water as an efficient way to minimize costs. The growing adoption of these alternatives is likely to hinder the demand for N-MDEA, which, in turn, could affect the expansion of the N-MDEA market in the near future. However, research and development activities will continue to drive the N-MDEA market during the forecast period.

Looking for Regional Analysis or Competitive Landscape in N-MDEA Market , ask for a customized report

Analysts’ Viewpoint

The N-MDEA market is expected to grow at a CAGR of ~6% during the forecast period. The ascending demand from the oil & gas sector will play an imperative role in driving the growth of the N-MDEA market in the near future. Research and development activities will gain significant momentum, as stakeholders continue to strive to reduce environmental footprint. Market players in the N-MDEA market should primarily focus on improving the energy efficiency of operations that utilize N-MDEA. Stakeholders should also consider mergers and acquisitions in Asia Pacific and MEA to improve their position in the current market landscape. The Asia Pacific region will continue to be the most prominent N-MDEA market, owing to India and China being two of the largest producers and consumers of N-MDEA.

N-MDEA Market: Overview

- N-Methyldiethanolamine (N-MDEA) is manufactured by ethoxylation of methylamine and ethylene oxide. It is extensively used for amine gas treatment and gas sweetening. Being a weak base, N-MDEA reacts rapidly with hydrogen sulfide and carbon dioxide in order to remove hydrogen sulfide and carbon dioxide, which is produced from natural gas and crude oil during the refining stage.

- Rise in air pollution emission limits by various governmental agencies across the globe is expected to drive the demand for gas treating process for emission of CO2. This, in turn, is anticipated to drive the demand for N-MDEA for absorption of CO2 and H2S gases in natural gas treatment.

N-MDEA Market: Key Growth Drivers

- N-MDEA offers excellent resistance to thermal and chemical degradation. Therefore, it is extensively employed in various industries such as textile, paints & coatings, and medical.

- Growth in population and increase in spending capacity of the middle class are some of the key factors driving the demand for fashion clothing. This is estimated to propel the textile industry over the next few years, thereby driving the demand for N-MDEA, as it is extensively employed in the production of soap emulsifying agents, lubricants, paraffin emulsions, and dyes in the textile industry. N-MDEA is commonly employed as an active substance in fabric softeners. It is a good alternative to TEA esterquats. It is also used in combination with perfluoroalkyl polymers in the production of silicone-based textile finishing agents.

N-MDEA Market: Key Challenges

- N-MDEA is employed as an intermediate in the synthesis of various products. It is used in diverse applications, including coatings, textile lubricants, polishes, detergents, pesticides, and personal care products due to its unique chemistry. N-MDEA possesses low toxicity. It does not cause any major side effects to the human body; however, prolonged exposure is likely to cause irritation to the eyes and skin.

- According to Regulation (EC) No 1272/2008 of the European Union, products containing N-MDEA are required to be labelled in accordance with the directive. Thus, implementation of stringent regulations is projected to hamper the global N-MDEA market in the near future.

Lucrative Opportunities in N-MDEA Market

- Manufacturers of N-MDEA are focusing on expanding their distribution channels to penetrate the market. Companies are expected to strengthen their sales in China, India, ASEAN, and the U.S. due to the significant expansion of textile, paint, and oil & gas industries in these countries.

- The gas treatment process is also used in the food & beverages industry. Rapid expansion of the food & beverages industry has led to an increase in requirement of thermal energy for conversion of raw materials into useful products. Growth in product innovation and R&D to enhance efficiency of products is also estimated to boost the market growth.

- Rise in awareness about the usage of natural gas as a source for electricity generation in developing countries such as China, Indonesia, and India is estimated to propel the gas treatment process in the near future. Furthermore, increase in environmental regulations on various industries to control air pollution in developed countries is anticipated to augment the demand for gas treatment process. This is projected to boost the demand for N-MDEA in order to suppress CO2 and H2S in the atmosphere.

Asia Pacific to Dominate N-MDEA Market

- In terms of value, Asia Pacific dominated the global N-MDEA market in 2018. India and China are the major producers and consumers of N-MDEA. China and India are also the major importers of N-MDEA across the globe. Expansion of industries such as paints & coatings, textiles, and oil & gas in Asia Pacific is a key factor augmenting the demand for N-MDEA.

- The N-MDEA market in China is dominated by a large number of oil & gas companies including Sinopec, CEFC China Energy, The Hong Kong and China Gas Company, Shaanxi Yanchang Petroleum, and China National Petroleum Corporation. Rise in the number of oil & gas companies is projected to propel the installation of gas treating process units for controlling the emission level in the atmosphere. This, in turn, is expected to drive the demand for N-MDEA as a solvent for absorbing CO2 and H2S.

Wide Application of N-MDEA in Oil & Gas Industry

- In terms of end user, the oil & gas segment constituted a major share of the global N-MDEA market in 2018. The segment is anticipated to continue its dominance during the forecast period, as N-MDEA is widely employed in gas treatment applications. N-MDEA is used for processes in refineries, petrochemical plants, and natural gas processing plants for gas treating process in the oil & gas industry.

- N-MDEA possesses properties such as low vapor pressure and excellent resistance to degradation of chemicals. This is estimated to drive the demand for N-MDEA in the oil & gas industry during the forecast period.

Leading Players Actively Engage in Joint Ventures and R&D Activities

- Key players operating in the global N-MDEA market include –

- Amines & Plasticizers Ltd.,

- BASF SE,

- Changzhou Yuping Chemical Co. Ltd.,

- Eastman Chemical Company,

- Huntsman Corporation,

- INEOS GROUP HOLDINGS S.A.,

- Jiangsu Taihu New Materials Holding Co. Ltd.,

- Sichuan Institute of Fine Chemical Industry Research and Design,

- Sintez OKA Group of Companies,

- The Dow Chemical Company,

- Yixing Xingguang Baoyi Chemical Co. Ltd., and

- ATHENA CHEMICAL TECHNOLOGIES.

These companies actively engage in expansions, mergers & acquisitions, and joint ventures in order to maintain their share in the global N-MDEA market.

- The Dow Chemical Company is leading a manufacturer and supplier of N-MDEA across the globe. The company’s products are manufactured at 164 sites in 35 countries globally. It manufactures more than 7,000 products across the globe.