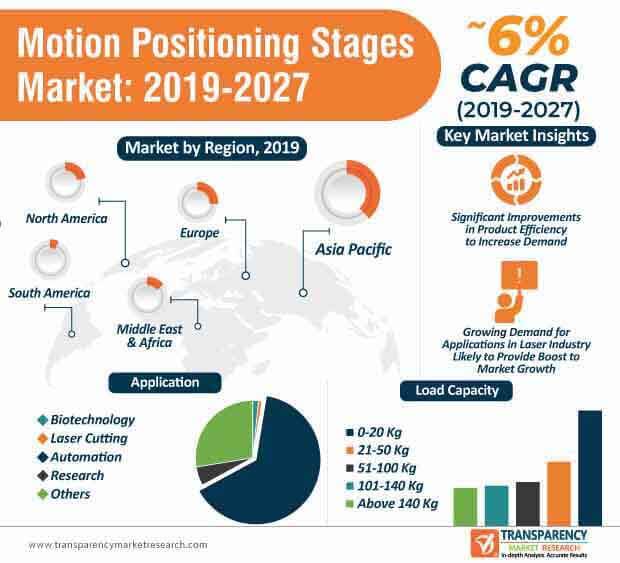

Motion positioning stages are highly critical for efficient machinery movement. As the industrial sector continues to experience waves of innovations and new developments, progress in motion positioning stages has played an important role in revolutionizing modern-day manufacturing processes. In addition, owing to significant advancements in technology, key participants in the motion positioning stages market are expected to fulfil evolving requirements of the industrial sector, which include high precision and enhanced productivity. Modern-day industrial applications require faster and finer motion control enabled by advanced motion control technologies. The growing need for highly precise motion control stages in an array of applications, including laser cutting, industrial automation, biotechnology, and research, among others, is expected to create significant demand for motion positioning stages during the forecast period (2019-2027).

With the advent of Industry 4.0, the industrial sector is shifting gears and leaning toward automated systems. Industrial automation has gained fast-paced adoption in the past few years and the trend is set to continue in the coming years. In their bid to gain a competitive edge, stakeholders in the current motion positioning stages market are increasingly focused on the development of power/energy-efficient products. The tectonic shift toward industrial automation is likely to provide an array of opportunities for key operators in the global motion positioning stages market, which is expected to reach a value of ~US$ 989 Mn by the end of 2027.

Request a sample to get extensive insights into the Motion Positioning Stages Market

Emphasis on Efficiency Expected to Increase Adoption in Multiple Applications

Due to technological developments, linear motors have evolved at a consistent pace in the past few decades, and offer greater accuracy and speed range. As linear motors continue to evolve, linear-motor applications are also evolving. With a growing focus on efficiency, at present, new applications of linear motors on axis have emerged, including automotive, material handlings, packaging, general automation, and off-highway, among others. Higher efficiency levels can be achieved with linear motors, owing to its direct-drive nature coupled with precise and faster strokes. Advanced linear motors with improved linear-motor designs integrated with new technologies are replacing other linear-motion alternatives.

To understand how our report can bring difference to your business strategy, Ask for a brochure

As per the findings of the research conducted by Transparency Market Research, the demand for linear stage motion positioning stages is expected to remain higher than that of rotary stages and goniometer motion positioning stages during the assessment period. The growing demand for linear stage motion positioning stages for industrial automation is anticipated to drive the growth of this segment during the forecast period. In the current scenario, a host of industrial applications is increasingly reliant on precise, accurate, and fast movement of machines. In addition, linear stage motors also fulfil the low maintenance and highly dynamic requirements of modern-day factories. The motion positioning stages market is likely to be primarily driven by new technologies that will lead to improvements in production processes. Current trends indicate a steady shift toward faster, smarter, and downsized motion control and positioning equipment.

Laser Industry Leveraging Benefits of Advanced Motion Positioning Stages

The demand for ball screws and powerful servomotors has gained considerable pace, particularly in high-force applications. As ball screw rails can be easily lubricated by end users, the demand for the same is expected to witness significant growth during the forecast period. The adoption of motion position stages such as ball-screws is on the rise, as machine manufacturers in the laser industry are continually finding ways to improve resistance and tolerance to extremely hot particulates. In addition, for design engineers in the laser industry who regard ease of installation as a critical criterion, the adoption of new-generation linear stages is expected to witness substantial growth, particularly for seamless alignment and placement on the machine base. Stakeholders in the current motion positioning stages market are increasingly focused on the development of new linear stages that are suitable for industrial applications.

Read Our Latest Press Release: