Multi-density Foams: Next Green Thing in the PET Foam Market

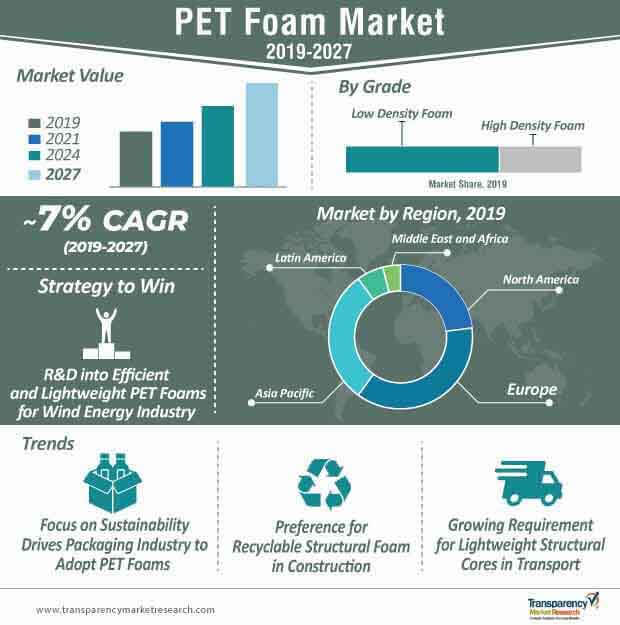

Polyethylene Terephthalate (PET) has penetrated across a wide range of applications in the composites industry, owing to its superior mechanical properties such as lightweight, high mechanical strength, and high temperature resistance, over other plastics. PET has witnessed high demand in the foam landscape, with a substantial rise in the applications of PET foam in transportation, wind energy, and packaging industries. However, the growing demand for environmentally-friendly plastics has influenced the trends in the PET foam market in recent years.

Leading manufacturers of PET foam are increasing their focus on research & development (R&D) activities to find new ways to produce PET foam boards with recycled materials, while maintaining the reliability of their structural properties. Manufacturers are developing multi-density PET foams to sync with the environment-driven trends in the composites industry, while meeting the stringent technical requirements of composite materials such as PET foam, which are developed by governing bodies. Increasing environmental awareness among customers is encouraging stakeholders in this landscape to introduce multi-density, recyclable alternatives to standard PET foams.

Request Brochure:

https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=5357

For instance, in May 2017, Armacell – a leading player in the PET foam market – announced the successful market launch of its innovative multi-density structural PET foam core. The company declared that, this innovation is directed towards catering to industries’ demand for combining different densities in one foam core and multiple core designs to enhance the point load resistance, while keeping the weight at its minimum. In September 2017, the company introduced its multi-density foam core made of 100% recycled PET, making the new PET foam recyclable until the end of its service life, in order to cater to the growing demand for environmentally-friendly structural PET foam cores in wide-ranging industrial applications.

In 2018, the global market for PET foam reached a valuation of ~US$ 194 million, and the sales of low-density PET foam accounted for over half the revenue share of the market. Nevertheless, multi-density PET foams are likely to emerge as one of the most popular choices for customers with most industries turning toward environmentally-viable materials, shaping the future of the PET foam market.

More Trending Reports by TMR:

Transportation Industry to Create Lucrative Sales Opportunities

The applications of PET foam in automotive and rail industries have been growing, as PET foam is being looked at as a viable option, mainly attributing to its light weight and high mechanical strength. Automotive and rail industries are being driven by the need for more energy-efficient and environment-friendly vehicles, without compromising on safety, and this will create new sales potential for PET foam in the transportation industry, in the coming years.

However, the application of PET foam is not limited to automotive and rail industries only, and is gradually gaining popularity, owing to the growing focus on sustainability. PET foam is being looked at as an ideal solution for marine applications. Manufacturers are looking at PET foam as it is sustainable, with superior thermal properties, along with being resistant to water absorption, as core materials in marine composite structures.

Manufacturers catering to the requirements of this industry include Gurit, with its recyclable PET foam-based products; and 3A Composites’ AIREX T90, a fire-resistant structural foam for mass transportation. These products are being manufactured not just to save resources, but also reduce operating costs and allow for economically-optimized road transport.

REQUEST FOR COVID19 IMPACT ANALYSIS:

https://www.transparencymarketresearch.com/sample/sample.php?flag=covid19&rep_id=5357

Wind Energy to go Fully Green with Sustainable PET Foam Structural Cores

The application of PET foam as a core material in windmills is gaining ground, as it is being employed in sandwich construction for blades, nacelles, and spinners. This comes due to a premium being placed on efficiency and versatility, and as such, the use of PET foam is becoming increasingly popular.

Manufacturers in the PET foam market are continuing to look into sustainable, yet efficient core elements for wind turbines. For instance, Armacell, a key player in the PET foam market, is looking at bigger and more efficient blades of windmills made from PET foam, due to its high temperature resistance, mechanical strength, and fatigue properties.

3A Composites, another global leader in the PET foam market, is enabling the use of environment- and resource-friendly materials in the manufacture of end products in the wind energy field. With renewability being an essential factor for growth and success, manufacturers’ R&D is now focused on reducing the burden on the environment.

Construction to Contribute Significant Demand to the PET Foam Market

The preference for lightweight materials in construction and architecture is taking on a bigger share of the market, as against traditional construction materials. The durability weight factor, along with ease in installation, has been driving the popularity of PET foam as a construction material. In 2018, the construction industry accounted for ~18% of the total market share, and this is unlikely to change during the forecast period.

The adoption of PET foam in construction has gained impetus due to the rapid pace of development around the world, especially in developing countries. The global construction sector is set to expand, particularly in the APAC region, which is certain to have an impact on the growth of the PET foam market. This can be attributed to the growing urban population, and increasing construction in the residential and non-residential sectors in the future.

Some of the key players in the market dealing in PET foam for construction include 3A Composites and Armacell International SA. 3A Composites’ structural foam AIREX is being marketed as sandwich composites for loadbearing and insulation in the same material. ArmaCell’s ArmaForm PET, a lightweight construction foam, is now being used at the economic railway stations in Saudi Arabia.