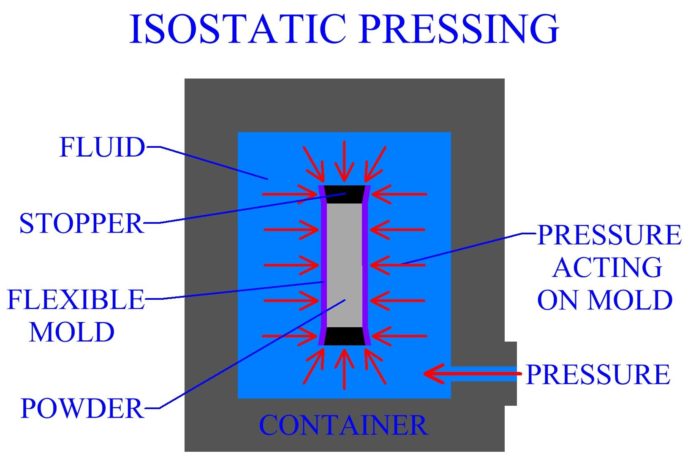

Isostatic pressing is a type of powder metallurgy (PM) forming process that puts equal pressure in all the possible directions on a powder. The pressure makes the powder highly compact and achieves maximum amount of density and uniformity without compromising the microstructure. The pressing is performed without the geometrical restrictions of the uniaxial pressing.

There are two types of isostatic pressing. First one is the cold isostatic pressing and the second one is the hot isostatic pressing. The cold isostatic pressing is used for compressing the green parts at a surrounding temperature whereas the hot isostatic pressing is used to completely consolidate parts at raised or higher temperatures through solid-state diffusion.

Some of the key insights about the global isostatic pressing market are given below:

- The global isostatic pressing market is divided into five key regions to give better understanding about its overall working dynamics. These regions are North America, Latin America, Middle East and Africa, Europe, and Asia Pacific. Of these regional segments, currently, the global isostatic pressing market is led by the North America region and is expected to continue to lead the market over the course of the given forecast period.

- The growth of the North America regional segment is primarily attributed to the growing demand for hot isostatic pressing products across several industries such as automotive, defense and military, aerospace, and manufacturing among others. Moreover, the presence of several leading manufacturers such as Synertech PM, Kittyhawk Products, American Isostatic Presses, and Quad City Manufacturing Laboratory among others are also helping to develop the isostatic pressing market in North America.

- The growth of the global isostatic pressing market is primarily driven by the increasing demand for low porosity and high density materials that are important for the production of 3D printed parts. In addition to this, the growing trend of producing products at a low cost that have a shorter life cycles are also helping to drive the growth of the global isostatic pressing market.

Isostatic Pressing Market – Introduction

Isostatic pressing is a process for forming powder metallurgy (PM). This process applies uniform pressure across all directions on a powder compact to achieve maximum uniformity of density and microstructure. Isostatic pressing is of two types, namely, hot or cold. Both of these manufacturing processes are used to improve the porosity of metals. Hot isostatic pressing (HIP) is used to fully merge parts at high temperatures by solid-state diffusion, while cold isostatic pressing (CIP) is used to compress green parts at ambient temperatures. Isostatic pressing method is widely used in different industries engaged in improving properties of applicable materials.

Isostatic Pressing Market – Competitive Landscape

Fluitron, Inc.

Founded in 1977, Fluitron, Inc. is headquartered in Ivyland, Pennsylvania, the U.S. The American technology company is involved in the designing and manufacturing of high pressure equipment and engineered products for use in chemical and other related industries. It has its operational units in Korea, South Africa, China, Japan, Taiwan, U.K., the Netherlands, Venezuela, and Canada.

Kobe Steel, Ltd.

Incorporated in 1905, Kobe Steel, Ltd. is based in Kobe, Japan. The company engages in the manufacture and sale of steel and iron. Kobe Steel, Ltd. operates through the following business segments: welding, aluminum and copper, iron and steel, construction machinery, machinery, power, engineering, and other businesses. Its product offering includes iron and steel, and aluminum and copper products such as steel casting and forgings, titanium, copper sheet, and strip and aluminum alloys. The company also offers metal recycling machinery, construction recycling machinery, resource recycling machinery, construction equipment, and forestry machinery.

To Get Glimpse of what our report offers, Ask for a Report Brochure here

Bodycote PLC

Established in 1923, Bodycote PLC is based in Macclesfield, the U.K. It engages in the provision of thermal processing services which comprises core technologies including hot isostatic pressing, metal joining, heat treatments, and surface technology. It operates through the Aerospace, Defense, and Energy; and Automotive and General Industrial segments.

Kennametal, Inc.

Founded in 1938, Kennametal, Inc. is based in Pittsburgh, Pennsylvania, the U.S. The company engages in the production of tungsten carbide metal cutting tooling. Kennametal, Inc. operates through the following business segments: infrastructure, widia, and industrial. It offers metal working and cutting tools, engineered components, mining, construction, and power material equipment. The company serves machinery operators, metalworking suppliers, manufacturers of transportation vehicles and systems; light machinery and heavy machinery industries; and airframe and aerospace components and systems.

Nikkiso Co., Ltd.

Incorporated in 1950, Nikkiso Co., Ltd. is located in Tokyo, Japan. It engages in the manufacture, sale, and maintenance of industrial and medical equipment. Its operations are carried out through the industrial and medical segments. The company also offers precision equipment including particle characterization instruments and multi-layer ceramic electronic component production equipment and systems; and carbon fiber reinforced plastic (CFRP) products such as aircraft components and carbon nanotube.

Some of the other significant players in the isostatic pressing market are Arconic (U.S.), American Isostatic Presses (API) (U.S.), Pressure Technology (U.S.), Engineered Pressure Systems (EPSI) (Belgium), and Shanxi Golden Kaiyuan (SXKYYC) (China) among others.

Isostatic Pressing Market – Dynamics

Application of Isostatic Pressing to Remain High in Aerospace and Defense Industries

Growth of aerospace and defense industries is positively impacting the adoption of advanced isostatic pressing method. Hot isostatic pressing (HIP) technology is used in developing stainless steel and nickel base superalloy which are used in the aerospace and defense industry for missile and space vehicle applications. HIP technology is also used to manufacture commercial aircraft. Aircraft parts and engines need to be high in density and low in weight to ensure great operational performance. HIP is deployed during the processing of these parts to develop a larger and more diverse set of aircraft and engine parts. Thus, HIP technology is expected to witness increasing application in aerospace and defense industry to enhance the material capabilities and process efficiency in the near future.

High Initial Investment and Operational Cost Associated with Isostatic Pressing Acts as a Major Restraint

Isostatic pressing technology involves high initial investment, and maintenance and operational cost. Also this technology comes with added cost such as consumption of electricity, gas, wear parts, and labor hours needed per cycle. Regular maintenance of equipment is also an element in the cost per cycle. The cost of the isostatic pressing cycle varies depending on the type of components to be processed, on the specific quantity of parts to be processed, and how the process is being done – either through a HIP service provider or through in-house operation. Hence, high initial set-up cost and operational cost associated with isostatic pressing is expected to hamper the growth of the market in the coming years.

To Get a Bird’s Eye View of Market Forecast, Ask for a Custom Report

Isostatic Pressing Market – Segmentation

The isostatic pressing market can be segmented based on:

- Offering

- Type

- Application

- Region

Isostatic Pressing Market Segmentation – By Offering

Based on offering, the isostatic pressing market can be fragmented into:

- Systems

- Services

Isostatic Pressing Market Segmentation – By Type

In terms of type, the isostatic pressing market can be bifurcated into:

- Hot Isostatic Pressing

- Small-Sized Hot Isostatic Pressing

- Medium-Sized Hot Isostatic Pressing

- Large-Sized Hot Isostatic Pressing

- Cold Isostatic Pressing

- Dry Bag Pressing

- Wet Bag Pressing

Isostatic Pressing Market Segmentation – By Application

Based on application, the isostatic pressing market can be segmented into:

- Aerospace & Defense

- Automotive

- Pharmaceutical

- Precision Machine Manufacturing

- Energy & Power

- Construction

- Semiconductors & Electronics

- Transportation & Logistics

Read Our Latest Press Release:

- https://www.prnewswire.com/news-releases/plastic-corrugated-packaging-market-expands-scope-of-businesses-in-ecommerce-industry-to-deliver-sustainable-packaging-solutions-tmr-301200091.html

- https://www.prnewswire.com/news-releases/increasing-disposable-income-and-infrastructural-development-activities-to-augur-well-for-the-global-welding-torch-and-wear-parts-market-tmr-301205014.html

- https://www.prnewswire.com/news-releases/interest-of-pharmaceutical-industry-in-bag-on-valve-bov-technology-market-driven-by-safety-criterion-global-revenues-to-surpass-us-500-1-mn-by-2024–301210826.html

About Us

Transparency Market Research is a next-generation market intelligence provider, offering fact-based solutions to business leaders, consultants, and strategy professionals.

Our reports are single-point solutions for businesses to grow, evolve, and mature. Our real-time data collection methods along with ability to track more than one million high growth niche products are aligned with your aims. The detailed and proprietary statistical models used by our analysts offer insights for making right decision in the shortest span of time. For organizations that require specific but comprehensive information we offer customized solutions through ad-hoc reports. These requests are delivered with the perfect combination of right sense of fact-oriented problem solving methodologies and leveraging existing data repositories.

Contact

Transparency Market Research State Tower,

90 State Street,

Suite 700,

Albany NY – 12207

United States

USA – Canada Toll Free: 866-552-3453