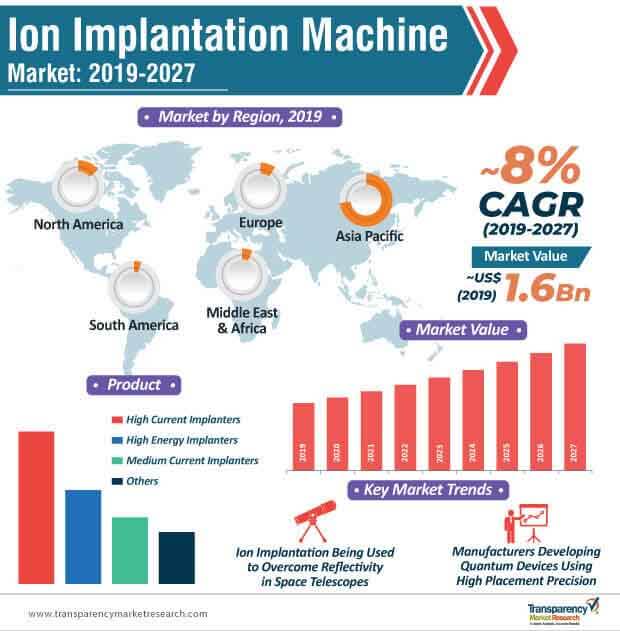

There is increasing demand for thin mirrors in space telescopes and X-ray telescopes to achieve high optical throughput. Advancements in the ion implantation machine landscape have helped achieve the accurate fabrication of thin mirrors. Ion implantation machines are used as a non-uniform integrated stress compensation (NISC) method to reduce coating stress by controlling deposition parameters, which lowers reflectivity. Thus, market players in the ion implantation machine landscape should innovate on compressive film stress in silicon mirrors for space telescopes and X-ray telescopes.

The ion implantation machine market is currently valued at ~US$ 1.4 billion (2018), and is anticipated to grow up to ~US$ 3 billion by the year 2027. Due to the high growth potential of the market, manufacturers are using ion implantation technology to develop image sensors. Metal contamination is a major challenge for extremely sensitive image sensors. That is why manufacturers are overcoming this challenge with the help of plasma shower using radio frequency.

Request a sample to get extensive insights into the Ion Implantation Machine Market

Semiconductivity and Quantum Components Pave the Way for Exponential Growth

The inception of semiconductors is the key driving force for technological development. The global semiconductor market was valued at ~419 billion in 2018, and is anticipated to transform semiconductor materials in the AI-driven (Artificial Intelligence) electronics and IoT (Internet of Things) space in the coming years.

Likewise, modern electronics are based on doped semiconductors. Due to the introduction of innovative electronic devices according to consumer needs, manufacturers in the ion implantation machine landscape are capitalizing on this growing trend. These manufacturers are catering to the needs of stakeholders in the electronics industry to synthesize electronic components with the help of dopant atoms to tailor semiconductivity, based on various applications in electronics.

To understand how our report can bring difference to your business strategy, Ask for a brochure?

Manufacturers in the ion implantation machine landscape are expanding their horizons to innovate on quantum components. This has created opportunities for manufacturers in the healthcare industry. The technology of ion implantation machines is being used to develop novel quantum-based biosensors that will play an important role in improving the study of human brain functions in the quantum and radiological science space. With the development of efficacious quantum components, manufacturers can increase production capacities for novel quantum computers and simulators.

Hybrid Tools and Dosage Control Overcome Technological Limitations

The ion implantation machine market is anticipated to experience steady growth in the coming years. However, manufacturers need to overcome challenges on the technology front.

For instance, the implanter injects dopants vertically into a substrate. However, in many cases, the implanter is required to inject dopants in tough angles, which could miss the target and impact the uniformity and yield of devices. As such, manufacturers are developing next-generation ion implantation machines that are more accurate and provide better dosage control for injecting dopants into substrates.

Another challenge that manufacturers come across is the difficulty of injecting dopants into tiny fins without causing damage. For this, manufacturers are innovating on a range of hybrid tools that combine the advantages of deposition and implantation.

Read TMR Research Methodology at: https://www.transparencymarketresearch.com/methodology.html

Read Our Latest Press Release: