Advancements in technology have led to the increase in adoption of bristle discs and brushes that keep workers protected from common wire brush-related injuries. As such, manufacturers in the industrial brushes market are increasing their production capabilities for bristle discs and brushes, owing to their advantages of ease of use and better performance. For instance, 3M— a leading U.S. multinational conglomerate is creating awareness about the advantages of bristle discs and brushes as opposed to traditional wire brushes where the former requires only a few changeovers in various end-use cases.

Novel bristle discs and brushes are being highly publicized for minimizing operator efforts and fatigue since the innovative brush bristle design deploys a continuous supply of abrasive mineral that reduces pressure in order to optimize cut rates. Modern bristle discs and brushes are creating safe working environments for workers in the market for industrial brushes, as these brushes do not emit harmful chemical vapors. Bristle discs and brushes are generating incremental opportunities for stakeholders in the industrial brushes market, as these brushes conform to hard-to-reach surfaces to achieve a consistent finish.

Request a sample to get extensive insights into the Industrial Brushes Market

Manufacturers Focus on Surgical Procedures and Cleaning Equipment for U.S. Military

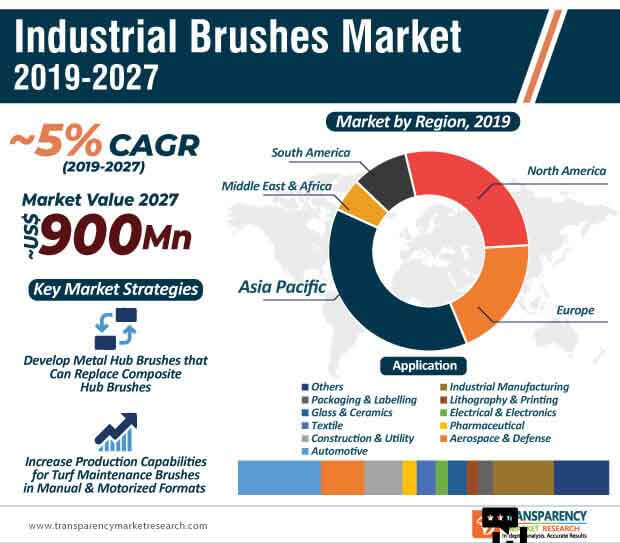

There is a growing demand for industrial brushes in automotive and industrial manufacturing applications. This is evident since the revenue of automotive applications is anticipated to be the highest among all applications in the market landscape where the global industrial brushes market is estimated to be valued at ~US$ 922 Mn by the end of 2027. On the other hand, the U.S. manufacturers are acquiring global recognition amidst tough competition due to the infiltration of low cost Chinese goods. For instance, Gordon Brush Mfg. Co., Inc.— one of the leading suppliers of custom brushes worldwide, was bestowed with the Patriot Award at the 2019 Made in America Convention in Indianapolis.

Manufacturers in the U.S. market of industrial brushes are increasing their production capabilities to serve applications in surgical procedures and cleaning equipment for the U.S. Military. This explains why North America is predicted to account for the third-highest revenue in the industrial brushes market by the end of the forecast period.

Can Foam Brushes Improve Washing Results?

Felt and conventional PE (Polyethylene) brushes are extensively used in tunnel systems. They are highly publicized for their top results in terms of cleaning, but certain drawbacks of these industrial brushes have led to innovations in foam brushes. For instance, Favagrossa— a manufacturer of industrial car wash brushes, has an extensive product portfolio in foam brushes under their CARLITE product line, that are overcoming drawbacks of traditional felt and PE brushes. The waterproof closed cell structure of foam brushes have an advantage over felt and PE brushes. Such product offerings are bolstering the industrial brushes market, which is estimated for a total output of ~56,700 units by the end of 2027.

To understand how our report can bring difference to your business strategy, Ask for a brochure

Novel foam brushes are quickly conquering the market for industrial brushes in order to achieve exceptional car washing results. Manufacturers are increasing their research spending to innovate in new materials that enhance car washing applications. Special attributes such as microfiber coating in foam brushes are encouraging competitive players in the industrial brushes market to increase their efficacy in patented technologies.

Machine Brushes Reduce Downtime and Meet High Tolerances in Commercial Printing Industry

Apart from automotive and aerospace applications, manufacturers in the industrial brushes market are exploring untapped business potentials in printing and packaging brushes. For instance, Tanis Incorporated— a leader of specialty-manufactured industrial brushes, has gained efficacy in the development of high-quality printing and packaging brushes that are being extensively used in the commercial print industry. Leading players in the industrial brushes market are increasing efforts to closely work with international equipment manufacturers to identify end user needs.

Standard brush assemblies help ensure reliability and quality in printing and conversion processes. As such, companies are focusing on improvements in 3D printing machine brushes. There is a growing demand for machine brushes in the printing industry to help reduce downtime and meet high tolerances during various procedures.

Read TMR Research Methodology at: https://www.transparencymarketresearch.com/methodology.html

Read Our Latest Press Release: