Soaring Global Demand for Steel to Augment Cut-to-length Line Systems Market

The manufacturing sector is experiencing a major transition worldwide due to major advancements in technology. At present, as Industry 4.0 continues to make inroads across a range of manufacturing facilities worldwide, the digitalization trend has well and truly set its foot into steel production– a factor that is positively impacting the long rolling space. The demand for cut-to-length line systems is witnessing significant growth, as steel producers continue to rope in significant efforts to fulfill the consumer demand for on-time delivery and product requirements while simultaneously running a lean operation. With advancements in sensor technology, long-rolling facilities are increasingly being designed to improve efficiency and optimize business and operating practices.

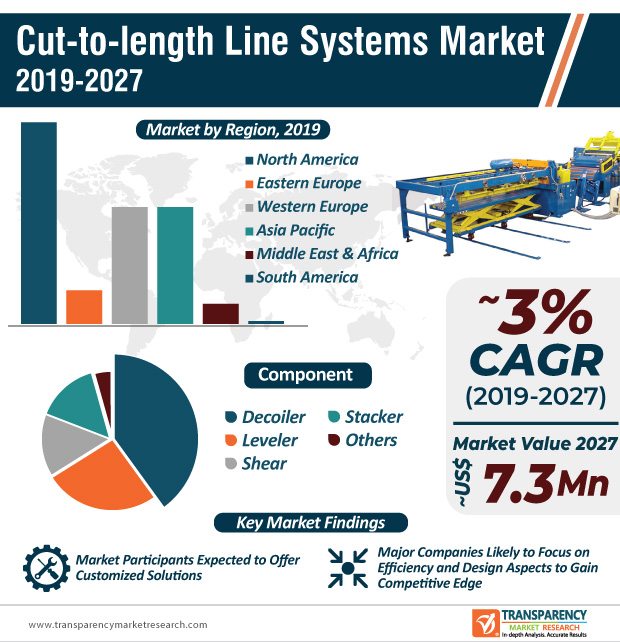

Key participants of the cut-to-length line systems market are likely to focus on the design of their product offering and offer customized solutions to their customers as per their requirement. In addition, companies are deploying resources to automate their existing strip feeding line with advanced technologies, including coiler, stamping technology, leveling technology, and shears, among others. Key companies in the cut-to-length line systems market are working on improving the performance of their cut-to-length lines by maximizing the speed of their production processes.

Get Sample Copy:

https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=70155

Growing Use of Smart Sensors Improves Cut-length Accuracy of Shears

Due to the onset of Industry 4.0, more number of manufacturing facilities are transitioning into smart factories. The sensor technology has evolved at a blazing pace in the past decade and thus, played an important role in hastening production processes. In addition, smart sensors also enable the integration of cutting-edge automatic functions, condition monitoring, and process models. Sensors are gradually becoming an integral part of several production processes and enabling significant improvements in cut-to-length line systems. Laser gauges play an imperative role in measuring product speed. Apart from improving the mill-control system and setup, these insights delivered by sensors play an essential role in optimizing the cut-length accuracy of shears. Moreover, the combination of non-contact laser gauges and vision systems, the mill-control systems tracks the height and width of the product within the mill line. Due to Industry 4.0, the adoption of automatic cut-to-length line systems is expected to remain higher than manual and semi-automatic cut-to-length line systems by a considerable margin. Rising investments and progress in cut-to-length line systems, along with infrastructure development across major manufacturing facilities are some of the major factors that will boost the prospects of the cut-to-length line systems market during the assessment period.

Manufacturers Aim to Improve Efficiency and Design of Cut-to-length Line Systems

The growing demand for stainless steel from a plethora of industries has directly impacted the demand for cut-to-length line systems. Companies in the current cut-to-length line systems market are likely to focus on cost-efficiency, designs, and the overall performance of their machines to fulfill the evolving requirements of customers. While top tier companies are expected to expand their product portfolio and global presence by eyeing mergers and collaboration opportunities in other regional markets, other established players operating in the current cut-to-length line systems market are focusing on offering customized machinery solutions in accord with the prerequisites of different applications.

Grab an exclusive PDF Brochure of this report:

https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=70155

For instance, in May 2019, Heinrich Georg GmbH Maschinenfabrik developed a customized solution for Vitkovicke Slevarny, spol.s.r.o. for the supply of a roll lath. The newly developed solution significantly improved the work compliance in the production lines for customers. Several manufacturers operating in the current cut-to-length line systems market are increasingly offering their machinery solutions for projects across the petrochemical, military, nuclear, metallurgy, etc. Expansion of the current production capacity, customization, and product diversification are likely to be the key growth strategies that will continue to gain traction in the cut-to-length line systems market as companies continue to strengthen their foothold in the current market landscape.

Request For Customization:

https://www.transparencymarketresearch.com/sample/sample.php?flag=CR&rep_id=70155

Analysts’ Viewpoint

The global cut-to-length line systems market is expected to grow a modest CAGR of ~3%, in terms of value, during the forecast period. The market growth can be primarily attributed to the surge in demand for steel and steel products and large-scale advancements in technology. The advent of Industry 4.0 will provide manufacturers in the cut-to-length line systems market with immense growth opportunities during the forecast period. Key participants of the market for cut-to-length line systems should focus on expanding their product portfolio and offering customized solutions to their customers to gain a competitive edge. On the regional front, North America and Western Europe are expected to witness development in the cut-to-length line systems in the upcoming years.

Cut-to-length Line Systems Market: Overview

- The global cut-to-length line systems market in terms of volume registered a CAGR of ~2% between 2019 and 2027. The cut-to-length line systems market is projected to be driven by growing demand for cut-to-length line systems from steel, aluminum, copper, and titanium producers. Cut-to-length line system manufacturers are adopting advanced technology to increase business agility and flexibility. For instance, in September 2018, Bollina Srl introduced ‘Bollina High Precision Levelling & Flying shear CTL Line” for color coated, pre-painted, and stainless steel materials with specification of 1250 * 0.35-1.5 mm. This is expected to boost the cut-to-length line systems market in the near future.

- The global cut-to-length line systems market is expected to reach US$ 7.3 Mn by 2027 from US$ 5.9 Mn in 2019. Rise in infrastructure developments continue to drive the demand for cut-to-length line systems from end users, thereby continuously pushing the demand for cut-to-length line systems.

- The cut-to-length line systems market in North America is anticipated to expand at a higher rate during the forecast period, followed by Europe

- Asia Pacific is projected to lead the global cut-to-length line systems market during the forecast period. This is primarily due to the emergence of new manufacturing plants in countries such as China, India, and in ASEAN, which is expected to create significant demand for cut-to-length line systems over the forecast period. China is the largest exporter of steel and India is the one of the largest producers of aluminium.

Cut-to-length Line Systems Market: Definition

- The cut-to-length line systems market report provides analysis of the global cut-to-length line systems market for the period 2017–2027, wherein 2018 is the base year, 2019 is the estimated year, and 2019 to 2027 is the forecast period. Data for 2017 has been included as historical information.

- In this report, we analyze the challenges industries face in acquiring the right cut-to-length line systems that can cope with the rapidly changing digital world. The report also highlights the total revenue generated through the sale of cut-to-length line systems and provides detailed insights about volume of these equipment across various key regions worldwide.

North America Cut-to-length Line Systems Market: Snapshot

- North America remains the leading market for cut-to-length line systems, with revenues in 2019 estimated at US$ 2 Mn. Emergence of new production facilities of steel, aluminum, copper, etc., and presence of large number of manufacturers of cut-to-length line systems are responsible for the growth of the cut-to-length line systems market in the region.

- The U.S. is expected to be the major shareholder in 2027. This is primarily due to the expansion of production capacity of manufacturing plants and establishment of new manufacturing plants across the U.S.

Key Growth Drivers of Cut-to-length Line Systems Market

- Increasing Demand for Better Infrastructure – The metal industry is a key sector as it provides material to various industrial sectors such as construction, manufacturing, aerospace, and automotive. Additionally, the metal industry plays an important role in economic development, infrastructure development, and strategic growth of a country. The metal industry has been witnessing significant increase in production capacity over the last decade due to increasing consumption and increasing need for metals across the globe based on parameters of quality, productivity, and reliability.

- In the steel sector, CTL systems are utilized to cut metal coils to a precise length. Demand for CTL systems is expected to increase during the forecast period to cater to the increasing demand for steel across the globe.

Key Challenges Faced by Cut-to-length Line Systems Market Players

- Cost of installation of cut-to-length line systems is significantly high, which is one of the negative factors that hinder the market across the world. This is primarily due to the cost of individual components such as coil handling, coilers, levelers, roller feeders, shears, and stackers is also high. Hence, majority of small-scale industries and lower-scale end-users are opting for leased and used machines.

- The global cut-to-length line systems market is influenced by rising competition among local and international companies. The market in Asia Pacific, especially in China, is primarily influenced by local players. This factor is likely to hamper the global cut-to-length line systems market during the forecast period.

Read TMR Research Methodology @:

https://www.transparencymarketresearch.com/methodology.html

Cut-to-length Line Systems Market: Competition Landscape

- In August 2019, Primetals Technologies Ltd. and steel producer Gerdau signed a strategic partnership for their digitalization journey, where digitalization projects on Gerdau sites in Brazil will be driven through joint development projects and by creating new business models

- In 2018, KOHLER Maschinenbau GmbH launched an economic compact strip feeding line and has also filed a patent for reversible levelling rollers for part levelling machines

Cut-to-length Line Systems Market: Company Profile Snapshot

- KOHLER Maschinenbau GmbH: Incorporated in 1963, KOHLER Maschinenbau GmbH is based in Lahr, Germany. KOHLER Maschinenbau GmbH provides levelling machines to sheet metal manufacturers. Its services include diagnostics, commissioning, maintenance & repairs, training, spare parts, and retrofitting.

- Primetals Technologies Ltd.: Incorporated in 2015, Primetals Technologies Ltd. is located in Wisconsin, United States. Primetals Technologies Ltd. is an engineering and plant construction company that serves clients in the metals industry. It is a global provider of technological solutions for iron making, steel making, continuous casting, hot/cold rolling, etc. and is one of the largest providers of metallurgical automation solutions in the world.

- Other major players operating in the global cut-to-length line systems market and profiled in the report include

- Heinrich Georg GmbH

- ACL MACHINE CO., LTD

- ANDRITZ AG

- ARKU GmbH,

- ATHADER S.L.

- Bollina srl

- Bradbury Co., Inc.

- Burghardt+Schmidt GmbH

- COE Press Equipment Corp.

- Delta Steel Technologies

- Dimeco Group

- F.I.M.I. FABBRICA IMPIANTI MACCHINE INDUSTRIALI SPA

- Shijiazhuang Teneng Electrical & Mechanical Equipment Co., Ltd.

- Sacform, and Fagor Arrasate.

- Companies are shifting toward advanced equipment and integrating new technologies to enhance production capacity to gain a competitive advantage in the cut-to-length line systems market apart from maintaining their position in the market.

Read Our Latest Press Release:

About Us

Transparency Market Research is a next-generation market intelligence provider, offering fact-based solutions to business leaders, consultants, and strategy professionals.

Our reports are single-point solutions for businesses to grow, evolve, and mature. Our real-time data collection methods along with ability to track more than one million high growth niche products are aligned with your aims. The detailed and proprietary statistical models used by our analysts offer insights for making right decision in the shortest span of time. For organizations that require specific but comprehensive information we offer customized solutions through ad-hoc reports. These requests are delivered with the perfect combination of right sense of fact-oriented problem solving methodologies and leveraging existing data repositories.

Contact

Transparency Market Research State Tower,

90 State Street,

Suite 700,

Albany NY – 12207

United States

USA – Canada Toll Free: 866-552-3453

Email: [email protected]