Composite Cans Market Analysis: Maximum of the Revenue to be generated by the Spiral Winding Segment in 2018

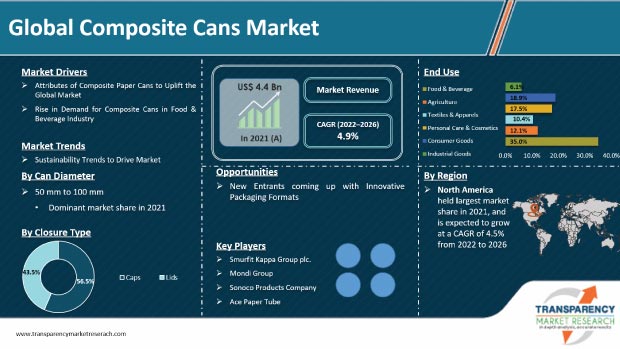

The global market for Composite Cans was valued at US$ 3,597.2million in 2017. The market is forecast to expand at a CAGR of 5.2% during the forecast period, 2018-2026.

Composite cans are cylindrical paper tube that usually has a body made of several layers of Kraft paper wounded by spiral, convolute and linear draw winding method. Spiral Wound Cans are made by diagonally winding and gluing four layers of material together. The bottom layer is usually tin or foil, the two middle layers are usually paper board, and they serve to give the can its structure. Composite Cans are used mainly for packaging everyday household items like coffee whiteners, diet drinks, bread crumbs, hot chocolate mixes, nuts, cakes, spices, tea, cleaning gels and baking sodas among others. Composite Cans offer several advantages such as cost-effectiveness, environmental safety (composite cans are mostly made from recycled products), durability, versatility and user friendliness in general. Child-resistant and tamper evident dispenser tops are available for product safety in composite cans. Composite cans are used to package dry beverages such as powdered drinks, tea and coffee. Composite cans are suitable for ambient and cold fill. Composite can characteristics include excellent interlaminate bond strength, high heat resistance, high splitting resistance of cardboard base, extended shelf-life due to aluminum barrier and great barrier against gas. Composite cans replace the tin containers since the latter are heavier, costlier and corrosive.

The global market for Composite Cans market is segmented as per closure type, production technique, can diameter and end use. Variety of closure options available for composite cans offer consumer convenience for product handling. Composite cans are available in various closures. Can closures can be made if materials such as metal, paperboard or plastic. A single can have more than one material closure. For instance; Pringles Chips composite can has an aluminum foil membrane and has a snap open lid made of plastic. The bottom end of the composite can is made of metal. Composite cans are also available with Re-sealable lids which protect the contents and allow multiple use. Light weight and eye catchy designs drives the market for global composite cans. Composite cans can be manufactured in almost any shape or size: tall and skinny, short and broad, easily meeting the consumer specific requirements. These variety of sizes in height and diameter allows composite cans to have a demanding presence on the retail shelf. The growing demand for potato chips is expected to fuel the composite cans market during the forecast period. Potato chips and crisps are one of the most popular snacks consumed worldwide.

Planning to lay down future strategy? Perfect your plan with our report brochure here https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=25085

Consumer preference for composite cans:

RESEALABILITY

Consumers disliked having to transfer food to another container after opening. Composite cans have an easy-to-reseal plastic lid, which means customers don’t have to transfer the food to a different container.

EASE OF OPENING

Consumers also disliked having to use a can opener to get into the packaging. Manufacturers are offering an easy-peel membrane and a resealable lid for the composite can. With this simple, peelable film or a quick pop of the lid, consumers can open the composite can right away without special equipment.

Customer and end-use consumer benefits:

Customer Benefits: Composite cans are easy to run on standard membrane sealing machines and seamers. Composite cans offer a simplified supply chain. Due to the light weight of composite cans they are easy to package and transport and saves shipping costs.

Consumer Benefits: Easy opening of the composite cans provide consumer convenience. High barrier options offer product freshness and aroma preservation.

Recent Developments:

- Manufacturers are attempting to have their composite cans certified as biodegradable. Companies are investing in R&D that will help find new components to the can bringing new options. Manufacturers are coming up with cardboard end, body and the bioplastic lid to keep the same preservation but to offer a new trend.

- Beverage packaging is undergoing several developments and one of them includes paperboard or composite cans for beverage packaging. These developments are pioneering in the aseptic can as well as the composite can packaging field. Composite cans are used to pack energy drinks in Germany. Composite cans are favored by European packaging laws and is classified as “Ecological Favorable Packaging”

- Sonoco, world’s largest producer of paperboard cans or composite cans, entered its UK subsidiary, the market for paperboard cans for liquids. Sonoco offered paperboard cans for the packaging of motor oils.

- Pangea Organics offers skincare products. The company provides facial and body care products. Pangea Organic’s packaging for Ecocentric body/skin care products is plantable. The composite can contains seeds of medicinal herbs that are present in the product packed in the box. After planting the box, medicinal herbs spring out of the seeds, giving the consumer the pleasure of growing flower by planting the empty jar.

Looking for exclusive market insights from business experts? Request a Custom Report here https://www.transparencymarketresearch.com/sample/sample.php?flag=CR&rep_id=25085

Spiral Winding segment of composite cans market was valued at US$ 2,041.4 million in 2017 and is expected to expand at a CAGR of 5.9% over the forecast period 2018-2026. On the basis of closure type, composite cans market is expected to create incremental $ opportunity of US$ 2,081.5 Million, during the forecast period. The Food & Beverage segment is valued at US$ 1,232.9 Million in 2017 and is expected to reach US$ 2,033.5 Mn, by the end of the forecast period (2016). Production Type segment is anticipated to register a CAGR of 5.2%, during the forecast period.

Competitive Landscape

Key players operating in the global market for Composite Cans include Sonoco Products Company, Amcor Ltd, Smurfit Kappa, Mondi Group, Ace Paper Tube, Irwin Packaging Pty Ltd, Halaspack Bt, Quality Container Company, Nagel Paper, and Corex Group Tinpak.

Contact

Transparency Market Research,

90 Sate Street, Suite 700,

Albany, NY 12207

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453