Bag-on-valve (B.O.V) technology is rapidly growing in packaging various pharmaceutical, personal care, home care products. Bag-on-valve technology provides an advantage for the aerosol products that require contact-free dispensing. Owing to the longer shelf-life, need of less or no preservatives, used with eco-friendly nitrogen or air, the bag-on-valve technology is being used on a large scale for cosmetics, food & beverages, and pharmaceutical packaging. Moving towards innovative and waste-reducing food packaging techniques. Major food companies are adopting bag-on-valve technology for packaging oil, sauces and other liquid and cream products. This is meeting consumer demand for convenience, easy-to-use and easy to store packaging.

According to the Aluminum Association, recycling aluminum can save a lot of money and also reduce energy consumption. Hence, increasing number of manufacturers are producing bag-on-valve packaging using aluminum. Moreover, aluminum has high recycling value without loss of any quality. B.O.V technology also results in reduced amount of volatile organic compounds. Healthcare and other industries are also choosing sustainable packaging options. Hence, the bag-on-valve packaging is emerging as the most-preferred choice for manufacturers in various industries.

Request for a sample:

https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=14594

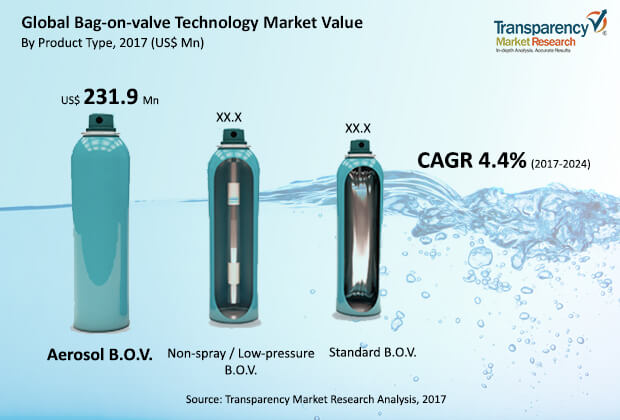

According to the report by Transparency Market Research, the global market for bag-on-valve technology is likely to see a moderate growth, registering 4.4% CAGR between 2017 and 2024. The global bag-on-valve technology market is also projected to bring in US$ 500.1 Million in terms of revenue.

Aerosol B.O.V. to Emerge as the Most Preferred Product in the Global Bag-on-valve Technology Market

Compared to the standard and non-spray B.O.V products, aerosol B.O.V. product is expected to be largely preferred product throughout the forecast period. By the end of 2024, aerosol B.O.V. is estimated to surpass US$ 300 Million in terms of revenue. Increasing number of pharmaceutical companies are producing spray products using aerosol B.O.V. The bag-on-valve includes rolled-up multi-layered pouch attached to the aerosol valve. Also, aerosol B.O.V. functions equally at all the angles and also add convenience to the formulation by eliminating the need for preservatives. Qualities such as easy to hold, lightweight, unbreakable are driving the demand for aerosol B.O.V. Manufacturers are developing aerosol cans using aluminum on a large scale, due to its recyclable nature and low cost.

Ask for brochure:

https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=14594

Bag-on-valve Technology to be Find Large Application in Cosmetics & Personal Care Industry

Increasing number of cosmetic and personal care products including deodorants, lotions, creams, self-tanning sprays, and products for personal hygiene are using bag-on-valve technology. It eliminates the contact between propellant and product, it makes possible to dispense product in all positions. Manufacturers are also providing a sterilized bag-on-valve system to provide a sterile environment for cosmetic products, ensuring the safety of the product. Companies are also working on coming up with new methods of filling up the product in B.O.V. The bag-on-valve technology which was first originated in the cosmetic industry is moving towards the pharmaceutical industry. The rise in the production of spray, wound cleansing products, dermal creams, disinfectant sprays is resulting in the increasing use of bag-on-valve technology. Moreover, bag-on-valve is classified as a medical device in Europe. Hence, registering a bag-on-device as a medical device is considered to be the most cost-effective way to enter the market in Europe.

Read Our Latest Press Release: