IIoT Enables Real-time Data Analysis and Averts Risks of Machinery Failures

The Industrial Internet of Things (IIoT) and Industry 4.0 revolution are adding great value to the development of energy, automotive, and other industries. Condition-based monitoring that involves real-time sensing and predictive data is adding great value to the oil condition monitoring services landscape.

Oil acts as an intimate inner working material for various complex components in engines, turbines, and hydraulic systems. Since oil is exposed to these components, its acts as a common medium in assessing the condition of the machine as well as the oil itself, which can be analyzed for the prevention of future equipment failure.

With the help of IoT (Internet of Things), oil samples are analyzed in laboratories, and the machinery can be analyzed in real time using online sensors. Industrial IoT in the oil condition monitoring services landscape is leveraged with portable data collectors, and operators can further investigate data records that reveal the health and aberrant condition of components. This data can pass through modems or industrial gateways for analysis and storage.

Request a sample to get extensive insights into the Oil Condition Monitoring Services Market https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=36209

Stakeholders Provide Predictive Maintenance Programs for Lubricant Analysis

The oil condition monitoring services market is highly consolidated. Due to high competition in oil condition monitoring (OCM), market players are devising predictive maintenance programs that aid clients in avoiding the risks of machinery and engine failure. These specialized programs track changes in the lubricant to provide early warnings of any restraining problems that might affect machinery operation.

In the oil condition monitoring services landscape, lubricants undergo high pressure temperatures, water contamination, and corrosion, and are exposed to air-ingested particles. These adversities pose high risk of machinery malfunction. With the help of analytical results through predictive maintenance programs, stakeholders can provide early remedial actions to mitigate costly component and system failures.

Market players are customizing online platforms that facilitate 24/7 online access for clients. These platforms directly send client-specific reports that provide data analytics and forecasts, review, and exporting of data. Stakeholders in the oil condition monitoring services landscape are also providing value-added services such as individual testing programs to run routine tests of lubrication oil and machinery.

Consultation through Performance Indicators Bridges Gap between Service Providers and Ship Operators

One of the challenges that market players in the oil condition monitoring services landscape come across is the demanding need for efficient oil and machinery condition monitoring services in ships. Since there is no standardization for ships, every ship is different, thereby requiring ship-specific data analysis. This creates an additional cost burden for operators in the marine industry to allocate separate funds for each ship, so as to acquire data related to any impeding condition of the lubrication oil and machinery.

Operators demand for the development of different analytic models for each vessel. Since condition monitoring plays an important role in the marine industry, stakeholders need to devise a robust mechanism to achieve the efficient reliability of components with a centralized monitoring facility. Thus, regular consultations between service providers in the oil condition monitoring services landscape and ship operators will help tackle the challenges of oil and machinery condition monitoring services in ships. This helps service providers in developing efficient condition monitoring plans that cater to the specific needs of operators.

Stuck in a neck-to-neck competition with other brands? Request a custom report on “Oil Condition Monitoring Services Market” https://www.transparencymarketresearch.com/sample/sample.php?flag=CR&rep_id=36209

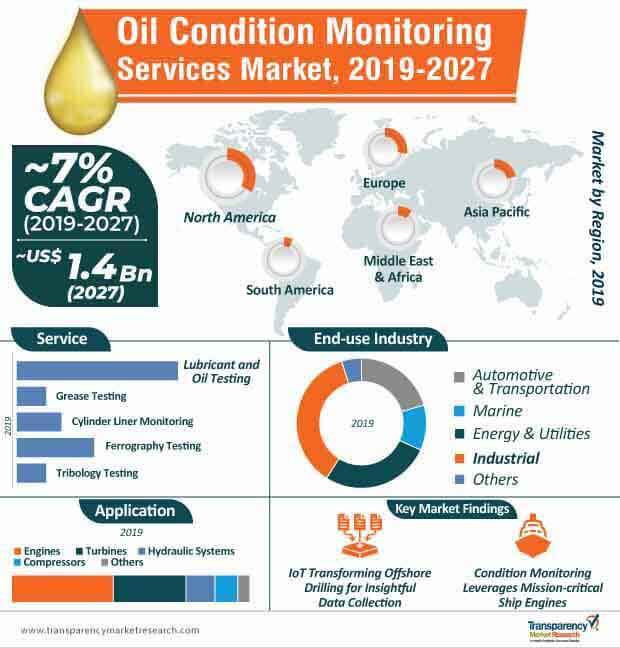

- According to Transparency Market Research’s latest research report on the global oil condition monitoring services market for the historical period of 2017–2018 and the forecast period of 2019–2027, the rising adoption of the predictive maintenance methodology for the maintenance and upkeep of machinery and equipment among industries is expected to boost the global oil condition monitoring services market during the forecast period.

- In terms of revenue, the global oil condition monitoring services market is estimated to reach a value of ~US$ 1.4 Bn by 2027, expanding at a CAGR of ~7% throughout the forecast period.

Rising Adoption of Predictive Maintenance Among Industries: A Key Driver

- For a long time, factory managers and machine operators have been carrying out scheduled maintenance and regular checks of various components in machinery and equipment in order to ensure their health and smooth functioning. However, almost 50% of all preventive maintenance activities proved to be ineffective.

- Over the last few years, the method of predictive maintenance has emerged, and has rapidly started gaining prominence among industry operators and asset managers. With the help of predictive maintenance, industries can evaluate the health of their assets and predict the time when a particular component or a system is likely to fail, and as such, needs replacement or repair.

- Owing to advantages such as reduced maintenance time, increased equipment lifespan, enhanced efficiency, and risen productivity, a growing number of organizations have started resorting to predictive maintenance analytics from targeted solutions, which includes oil condition monitoring services.

- Oil condition monitoring is a vital element of the predictive maintenance schedule of equipment, and it helps companies identify machine wear before it leads to any serious breakdown. With the rising price of crude oil and improvements in the quality of the lubricants, it is more important for industries to maximize the service life of the oil in use. Hence, oil condition monitoring services are increasingly being adopted.