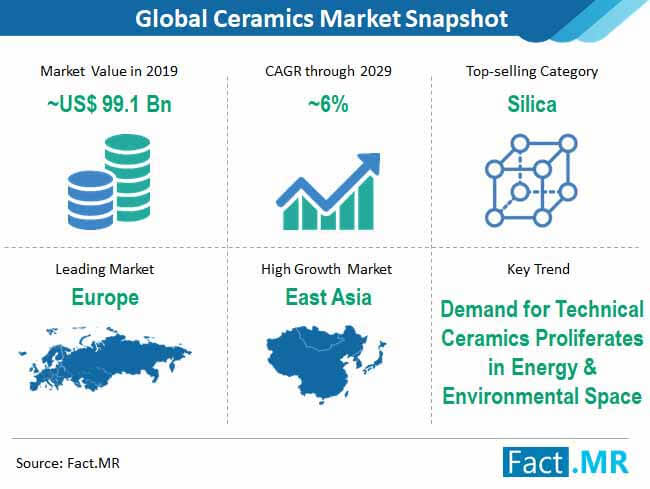

Global ceramics consumption volume was recorded ~462 thousand KT in 2018, which is anticipated to see a healthy ~5% Y-o-Y increase in 2019. The latest report published by Fact.MR reveals a promising growth outlook for the global ceramics market, over the course of coming years.

The clamor for optimal efficiency has fueled innovations and developments in passive electronic components landscape.

The demand for passive components is significantly taking off, owing to their abilities to control the electron flow in a circuit. Ceramic capacitors represent a bulk of the overall passive component demand and are being actively sought-after across multiple Industry verticals.

Request for Sample https://www.factmr.com/connectus/sample?flag=S&rep_id=3846

Ceramic-based electronic components, such as ceramic capacitors, are emerging as viable alternatives to the metal and plastic variants for elevating the efficiency a notch higher. Ceramic capacitors are being actively embraced across multiple industry verticals, such as consumer electronics, telecommunication, automotive, and many more.

Lately, various industry verticals are showing notable preferences for multilayer ceramic capacitors (MLCCs) on the back of multiple performance advantages coupled with substantial cost savings.

The Fact.MR study highlights the growing demand for technical ceramics from the energy & environmental space. Increasing need for operational safety and low-wear process control has necessitated the adoption of advanced ceramics, also known as technical ceramics, in energy supply and environmental technology spaces.

Technical ceramics help in curbing emission levels and facilitates optimal resource utilization and further enhancing their visibility across multimodal energy and environmental applications.

Competency in handling extreme temperatures and mechanical stresses is upholding the importance of technical ceramics across diverse applications, including power plant engines & turbines, photovoltaic systems, solar thermal energy conversions, and wind & water power. This, in turn, is creating sustained opportunities for the manufacturing companies to make headway with business expansions.

Additive Manufacturing – Potential Solution to Die Lock Issues

3D printing or additive manufacturing (AM), notably referred to as 3D printing, is the most recent addition to the overall manufacturing process for ceramic parts’ production.

With ‘Lithography-based Ceramic Manufacturing (LCM)’ being the industry-specific name, this process is gaining notable favor owing to its ability to overcome die-lock products encountered during complex geometries, which remains unaddressed in case of traditional injection molding methods.

Request for Methodology https://www.factmr.com/connectus/sample?flag=RM&rep_id=3846

LCM not only reduces the wait time but also helps in significant cost reductions. Tooling-free LCM processes offer high convenience to producer-limited quantities of custom parts at reasonable costs, helping manufacturers to attain competitive benefits.

Ceramic parts produced via LCM process are typically smaller and contains the number of features than an injection-molded part, while they are subjected to similar quality standards. Demand for technical ceramics in emerging countries is subjected to an increase at the significant growth rate.

According to the study, ceramics are widely used in the construction industry that is growing at a steady pace all over the world, specifically in developing regions.

The demand for construction in the housing as well as commercial sector is increasing because of growing economies, urbanization, per capita income, and spending, GDP growth, population expansion.

In addition, the fulfillment of the demand for better aesthetic design, and structural reliability and sustainability of buildings without a significant increase in prices has been achieved due to the effective use of ceramics.

Sustained demand for ceramics from the construction sector will continue to remain a key driving force for the ceramics market across the globe.

Fact.MR’s analysis also suggests that the despite the market is operated by several leading players as well as multiple smaller companies, at regional and global level, there are ample companies that maintain the focus on exclusively delivering high-quality ceramics. Major vendors have increased their R&D activities for new applications, and increasing use of traditional and advanced ceramics in various industrial end users, thereby escalating the demand for ceramics.

Connect To an Expert https://www.factmr.com/connectus/sample?flag=AE&rep_id=3846

About Fact.MR

Market research and consulting agency with a difference! That’s why 80% of Fortune 1,000 companies trust us for making their most critical decisions. While our experienced consultants employ the latest technologies to extract hard-to-find insights, we believe our USP is the trust clients have on our expertise. Spanning a wide range – from automotive & industry 4.0 to healthcare & retail, our coverage is expansive, but we ensure even the most niche categories are analyzed. Our sales offices in United States and Dublin, Ireland. Headquarter based in Dubai, UAE. Reach out to us with your goals, and we’ll be an able research partner.

Contact:

US Sales Office:

11140 Rockville Pike

Suite 400

Rockville, MD 20852

United States

Tel: +1 (628) 251-1583

E: sales@factmr.com

Corporate Headquarter:

Unit No: AU-01-H Gold Tower (AU),

Plot No: JLT-PH1-I3A,

Jumeirah Lakes Towers,

Dubai, United Arab Emirates