Fiber-reinforced Composites Market – Snapshot

Fiber Reinforced Composites are made by combining two or more materials (fibers with matrix materials) to give a unique combination of properties It consists of a continuous phase called the matrix and a dispersed phase called the reinforcement. There are three basic types of composites: metal matrix composites (MMC), non-metal matrix composites (CMC), and polymer matrix composites (PMC). These are used in various end-use industries such as construction, transportation, industrial, sports, energy, aerospace, consumer goods, and electrical & electronics.

The global fiber reinforced composites market is expected to expand at a rapid pace during the forecast period owing to increase in demand for lightweight vehicles. Automotive manufacturers and OEMs are seeking innovative materials to reduce vehicle weight and achieve fuel efficiency and carbon emission targets due to stringent environmental norms and government regulations. Composites offer several structural and weight advantages over traditional steel and injection molded automotive parts. These are used as raw material to manufacture various structural, interior, exterior, and other automobile components. Composites offer high stiffness, tensile strength, temperature tolerance, low weight, and thermal expansion; therefore, these are preferred to manufacture automobiles. For instance, polymer-reinforced composites offer excellent crash performance as compared to traditional steel. While the latter typically absorbs only 35J/kg of energy, thermoset composites absorb nearly twice of this, and thermoplastic composites 5-6 times more energy than steel. Therefore, along with weight reduction, composites in vehicles offer better safety. These factors are anticipated to drive the fiber reinforced composites market during the forecast period.

More Trending Reports by TMR:

Composite components require complex manufacturing process and high cycle time. Manufacture of components from substitute materials such as engineered plastics, TPOs, TPUs, aluminum, and other metal alloys is easier and they can be mass-produced in a shorter duration. Hence, availability of substitutes such as engineered plastics, TPOs, TPUs, aluminum, and other metal alloys and high cost of composites compared to traditional materials are likely to restrict the fiber reinforced composites market during the forecast period.

Growing need for lightweight and high strength material in automotive, aerospace, and wind mill applications is anticipated to create lucrative opportunity for fiber reinforced composites market in the forecast period. Innovations and developments to reduce the price of carbon fibers offer profitable opportunities for both carbon fiber and composite manufacturers. However, the expensive nature of composites is restricting its use in many applications which is acting as a threat to the fiber reinforced composites market during the forecast period.

The polymer matrix segment is estimated to expand at a rapid pace during the forecast period, as they offer high strength at low weight, ability to retain under in-service conditions, compression, fatigue and electric properties; which enhance the overall efficiency of fiber-reinforced composites. This, in turn, drives the demand for polymer matrix fiber reinforced composites. The non-metal matrix fiber reinforced segment is projected to witness considerable demand in the next few years, as it includes ceramic matrix composites, carbon matrix & graphite matrix composites, & others. Ceramic matrix composites constitute major share in the non-metal matrix composites. These properties are projected to fuel the polymer matrix segment during the forecast period.

Buy Now:

https://www.transparencymarketresearch.com/checkout.php?rep_id=1914<ype=S

The global fiber reinforced composites market witnessed various developments and technological advancements. For instance, In April 2018, the company, E. I. du Pont de Nemours and Company announced an expansion in manufacturing capacity by investing approximately US$ 100 Mn in the Sabine River Works (SRW) plant in Orange County, Texas. The expansion is expected to support global growth of the company’s specialty materials business. Also, In March 2015, in Ludwigshafen, BASF and SGL Group announced the joint research of a new composite material system. The system’s objectives are to improve the cost-effectiveness of the manufacturing of thermoplastic carbon fiber composites. These developments are anticipated to drive the global fiber reinforced composites market during the forecast period.

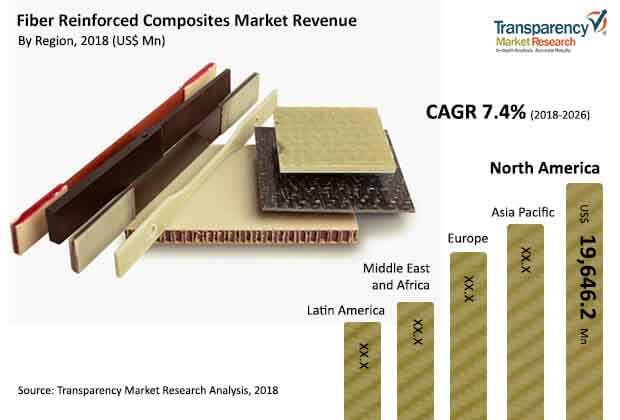

In terms of revenue, North America accounted for a significant share of the global market in 2017. The market in Asia Pacific is expected to expand at the maximum CAGR during the forecast period, followed by North America and Europe. In terms of market capitalization, Asia Pacific and North America lead the global market. The trend is expected to continue during the forecast period. However, the market in Asia Pacific is projected to expand considerably from 2018 to 2026, owing to rising investments in building & construction owing to rapid industrialization and urbanization. This, in turn, is projected to drive the fiber reinforced composites market in Asia Pacific during the forecast period.

Key players profiled in the global fiber reinforced composites market are BASF SE, E. I. du Pont de Nemours and Company, Hexcel Corporation, Huntsman International LLC., Reliance Industries Limited, Owens Corning, Toray Industries Inc., TPI Composites, Inc., Nippon Electric Glass Company Limited, Kineco Kaman Composites-India Private Limited, PLASAN CARBON COMPOSITES, RTP Company, Enduro Composites, Inc., COTESA GmbH, HITCO Carbon Composites, Inc., The Quadrant Group of Companies etc. Major players are adopting strategies such as increase in production capacities, geographical expansion, and upgrades in existing solutions and offerings.