Synthetic and Biobased Butadiene Market – Snapshot

Synthetic butadiene and biobased butadiene, termed as 1,3-butadiene, are non-corrosive, colorless gases that condense to a liquid form at -4.5°C.

Read report Overview-

https://www.transparencymarketresearch.com/synthetic-and-bio-based-butadiene-market.html

They have a mild aromatic odor. Synthetic butadiene is produced commercially by refinement of crude butylene concentration (C4) stream, a by-product of ethylene and propylene production.

Based on product type, the synthetic and biobased butadiene market can be bifurcated into synthetic and biobased. Synthetic was the leading segment in 2017 due to the wide consumption of synthetic butadiene in various end-uses including production of SBR, PBR, SB latex, NBR, and ABS.

Request Brochure @

https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=493

High crude oil prices and low natural gas prices in the U.S. have compelled petrochemical companies to shift their focus from oil-based naphtha cracking to natural gas-based ethane cracking. This has adversely affected the supply of butadiene. In turn, this has stimulated interest in on-purpose butadiene production from conventional and renewable feedstock. Interest in green tires has also been rising. These tires are manufactured from synthetic rubber derived from biobased monomers such as bio-isoprene and bio-butadiene. Genomatica and Cobalt Technologies entered into an agreement to produce biobased butadiene at their commercial plants within the next five years.

REQUEST FOR COVID19 IMPACT ANALYSIS –

https://www.transparencymarketresearch.com/sample/sample.php?flag=covid19&rep_id=493

More than 75% of synthetic and biobased butadiene produced worldwide is primarily used in rubber products and the automotive industry. In rubber compound materials, synthetic and biobased butadiene are blended with natural and synthetic elastomers along with various processing oils. Then, they are heated to produce SBR, PBR, SB latex, ABS, adiponitrile, etc. Synthetic and biobased butadiene are used as rubber-reinforcing agents in the tire manufacturing industry due to their ability to provide better reinforcement and improved resilience, tear strength, conductivity, and other physical properties. PBR and SBR are employed in treads, sidewalls, and inner liners; non-tire applications such as mechanical rubber goods (MRG) including industrial rubber goods, membrane roofing, and automotive rubber parts (sealing systems, hoses, and anti-vibration parts); and general rubber goods such as hoses, belts, gaskets, and seals. SB latex is used in specialty sectors such as paints & coatings. ABS is largely employed in lightweight vehicles.

In terms of value, the global synthetic and biobased butadiene market is anticipated to expand at a CAGR of more than 5.4% from 2018 to 2026 to reach US$ 27966.0 Mn by 2026. In terms of volume and value, the synthetic segment held major share of more than 90% of the market in 2017. Biobased is a rapidly expanding segment of the market, led by the rise in demand for biobased butadiene in green tires and increase in environmental concerns.

Increase in demand for synthetic and biobased butadiene in automotive and rubber industries is anticipated to propel the market. Volatility in prices of raw materials (such as c4 mixed and oil butadiene feedstock) and hazardous gases emitted into the atmosphere during the manufacture of synthetic butadiene are major factors restraining the global synthetic butadiene market. A few substitutes for synthetic butadiene such as biobased derived butadiene and silica are available in the market. However, biobased derived butadiene is considered as internal substitute for synthetic butadiene.

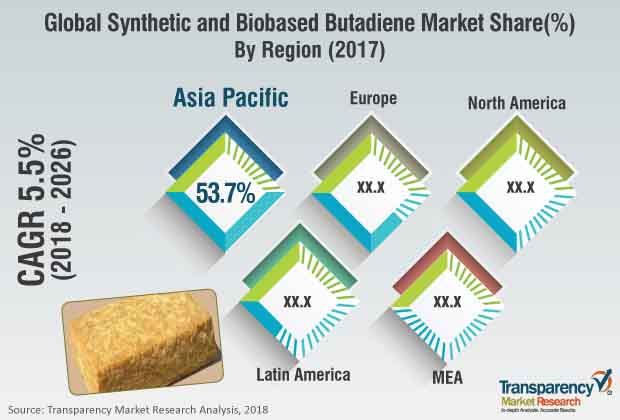

In terms of volume, Asia Pacific held the leading share of more than 50% of the global synthetic and biobased butadiene market in 2017. China is a major producer of synthetic and biobased butadiene with a few major producers operating in the market in the country along with several small manufacturers. India is a key importer of synthetic and biobased butadiene from China.

China and India account for majority of the demand for synthetic and biobased butadiene in Asia Pacific due to the expansion in tire manufacturing and paints & coatings industries in these countries. Asia Pacific is estimated to maintain its dominance in the global market throughout the forecast period. Tire manufacturers and the automotive industry are shifting their production base to developing countries in the region. The market share of Asia Pacific and Middle East & Africa is expected to increase at a rapid pace. Easy availability of crude oil and raw materials for the production of butadiene is encouraging prominent players to commence operations in these regions. Additionally, emerging economies of GCC countries are likely to propel the automotive industry in Middle East & Africa. This, in turn, is augmenting the synthetic and biobased butadiene market. The market share of North America, Europe, and Latin America is projected to rise at a sluggish pace between 2018 and 2026.

Around 70%-75% of the global synthetic and biobased butadiene market is consolidated, while the rest is fragmented. A few small players operate in the market. High degree of competition exists among market players. The market is dominated by large players. Prominent players profiled in the report are BASF SE, Eni S.p.A., Evonik Industries, Exxon Mobil Corporation, Petrochemical Corporation of Singapore Pte. Ltd., Repsol Group, Royal Dutch Shell Plc, Saudi Basic Industries Corporation, The Dow Chemical Company, TPC Group, Yeochun NCC Co., Ltd., INEOS Group AG, LyondellBasell Industries N.V., and Nizhnekamskneftekhim.