Reciprocating compressors are, primarily, positive-displacement machines. It compresses and move gases by producing linear (reciprocating) and rotational motion. The compressors are deployed to enhance the pressure level of the compresses gas.

Owing to functions of the reciprocating compressor, it is widely employed in oil & gas industry, refineries, gas processing plants, gas pipelines, and many others.

Further, it is an ideal solution for industrial requirements and low space locations. Hence, demand for reciprocating compressor is growing from LNG & CNG transport and refineries. Growth in the demand rate is attributed to reliability and efficiency of the compressor. Also, it is ideal for consistent duty operation.

All these aforementioned factors are likely to fuel growth of reciprocating compressor market in coming years.

Meanwhile, rising demand for oxygen supply across steel and iron industry is anticipated to, further, push horizon of the reciprocating compressor market.

Reciprocating Compressor Market – Snapshot

Reciprocating compressors finds extensive use in the manufacturing of chemicals and petroleum. Utilization in these processes comprises use in the transportation of natural gas and compression of gas. In addition to that, reciprocating compressors are substantially used in a wide range of processes in various industrial sectors such as pharmaceutical, power generation, refrigeration, metal processing, oil and gas, and chemicals. Such wide scope of application is likely to work in favor of the global reciprocating compressor market in the near future.

In the last few years, shareholders in the global reciprocating compressor market are expected to shift their focus on managing heat efficaciously, helping in rotation, narrowing the flow of gas, and improving the durability of the machine,

Rising Demand from Several End Use Industries to Boost Market Growth

A rise in the demand for these compressors from CNG and LNG transport and storage plants and refinery are likely to shape the contours of the global reciprocating compressor market in the near future. However, the fraudulent imitation of the designs of these compressors and high competition in price are likely to emerge as growth restraining factors for the global reciprocating compressor market.

Apart from that, the reciprocating compressors come with excellent features such as excellent performance in both high pressure and power. This factor is likely to pave way for the rapid revenue generation of the global reciprocating compressor market.

These compressors are used in a large number of industries, some of which are

- Natural gas processing plants

- Oil refineries

- Chemical plants

- Gas pipelines

- Refrigeration plants

One specialty application of reciprocating compressor comprise the blowing of plastic bottles that are made of polyethylene terephthalate or PET. In addition, the production processes of iron and steel are increasingly making use of these compressors, which is estimated to fuel the growth of the global reciprocating compressor market in the near future.

High Demand for Cost-efficient Reciprocating Compressors

Reciprocating compressors are extensively used in the production of chemicals and petroleum, including natural gas transportation and gas compression. In addition, reciprocating compressors find applications in an array of industrial sectors, including oil & gas, chemicals, refrigeration, metal processing, power generation, and pharmaceutical. In recent years, stakeholders in the reciprocating compressor market are expected to focus on improving the machine’s durability, assisting in rotation, narrowing gas flow, and managing heat efficiently. Some of the major components of a reciprocating compressor include pistons, piston rings, frames, cylinders, crossheads, and valves. Key manufacturers of reciprocating compressors are aiming at improving the quality of these components to optimize the performance of their products.

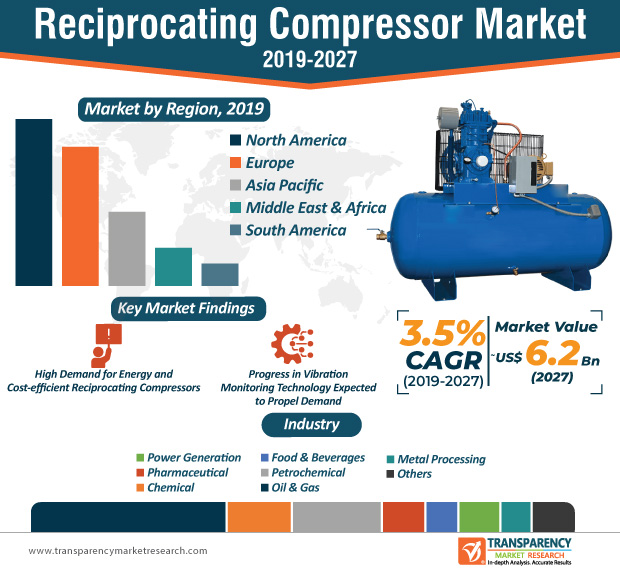

Improving the compressor efficiency is a major area of focus for the players operating in the current reciprocating compressor market landscape. In the past couple of decades, manufacturers have launched reciprocating compressors that are specifically designed to function in a duty cycle rather than operating continuously. Despite the entry of other variants of compressors such as screw compressors, the demand for reciprocating compressors is relatively higher, owing to a range of factors, including cost-efficiency, less maintenance, and exceptional capabilities of operating in hostile working environments. Due to these factors coupled with fast-paced technological advancements, the global reciprocating compressor market is expected to reach a value of ~US$ 6.2 Bn by the end of 2027.

Request a sample to get extensive insights into the Reciprocating Compressor Market

Progress in Vibration Monitoring to Boost Demand

Vibration monitoring has remained a key aspect within the reciprocating compressor market for several decades. The last 20 years witnessed significant development in vibration monitoring, which has progressed from RMS vibration transmitters to the currently deployed first-generation shock monitoring technology. Multiple manufacturers of reciprocating compressors are focusing on improving the overall thermodynamic efficiency and monitor pressure pulsation, wherein piping vibration is a critical parameter. The demand for reciprocating compressors is expected to grow at a steady pace, owing to their usefulness in compressing industrial and medical gases such as hydrogen, oxygen, helium, etc. However, undetected and unresolved faults could cause immense damage to reciprocating compressors due to which vibration monitoring is critical.

To understand how our report can bring difference to your business strategy, Ask for a brochure

Moreover, as these faults can develop at a rapid pace, vibration monitoring has gained significant importance in recent years. End users of reciprocating compressors are highly inclined toward round-the-clock process monitoring, as information can be continually recorded and analyzed with the help of a range of monitoring systems, including distributed control systems (DCS), a programmable logic controller (PLC) and supervisory control and data acquisition (SCADA) system. The advent of first-generation shock monitoring technology has played an important role in improving vibration monitoring, thereby minimizing the damage to reciprocating compressors in the long run. Although the first generation shock monitoring technology provided considerable improvements as far as vibration monitoring is concerned, stakeholders in the reciprocating compressor market were seeking solutions for a range of issues. These unaddressed issues left a door open for the development of second-generation shock and vibration technology – providing significant improvements in vibration monitoring and fault detection.

Replacement Demand and Innovations in Technology to Propel Market Growth

Some of the leading factors that are expected to fuel the growth of the global reciprocating compressor market include technological innovations, industrialization, investments, and replacement demand. As stakeholders continue to introduce advanced and improved variants of reciprocating compressors, the demand from end-use industries such as petrochemical, chemical, and power generation, among others, is expected to move in an upward trajectory during the forecast period. While there are significant improvements in the supply side, consumer appetite for improved and advanced machinery will continue to influence the demand for reciprocating compressors in the coming years. New technologies have paved the way for efficient and cost-effective reciprocator compressors due to which, consumers are increasingly opting to replace their machines on a regular basis.

While these factors will continue to trigger the demand for reciprocating compressors, industrialization in developing regions of the world such as Asia Pacific, Latin America, and Africa will provide plentiful opportunities for stakeholders in the reciprocating compressor market during the forecast period.

Stuck in a neck-to-neck competition with other brands? Request a custom report on Reciprocating Compressor Market

Reciprocating Compressor Market: Overview

- The global reciprocating compressor market, in terms of value, is expected to expand at a CAGR of 3.5% between 2019 and 2027. The reciprocating compressor market is projected to be driven by growing adoption of reciprocating compressors in iron and steel production processes. Reciprocating compressor manufacturers are adopting advanced technology to increase business agility and flexibility. For instance, in April 2019, Burckhardt Compression AG, a manufacturer of reciprocating compressors, introduced Laby compressors for LNG carriers with X-DF propulsion system. This is expected to boost the reciprocating compressor market in the near future.

- The global reciprocating compressor market is expected to reach ~US$ 6.2 Bn by 2027 from ~US$ 4.8 Bn in 2019. Technological innovation continues to drive the demand for reciprocating compressors among industries, thereby continuously pushing the demand for reciprocating compressors.

- The reciprocating compressor market in North America is anticipated to expand at a rapid pace during the forecast period, followed by Europe

- North America remains the leading market for reciprocating compressor, with revenues in 2019 estimated at US$ 1,792.6 Mn. Demand for reciprocating compressors is increasing in North America due to increasing demand for natural gas as the preferred fuel option, owing to its low-cost and low emission properties.

- Asia Pacific is projected to lead the global reciprocating compressor market during the forecast period. This is primarily due to the rising demand for petrochemical products such as ethylene derivatives, propylene derivatives, and aromatic products in the region. According to Hydrocarbon Processing’s Construction Boxscore Database, more than 280 new petrochemical projects were announced from 2016–2018. Asia Pacific has been the leader in new petrochemical projects accounting for nearly 34% (158 projects) new petrochemical projects.

- Additionally, increasing environmental consciousness and initiatives of the Chinese government has led to stricter regulations to improve air quality, which is expected to create significant demand for reciprocating compressors over the forecast period

Reciprocating Compressor Market: Definition

- The reciprocating compressor market report provides analysis of the global reciprocating compressor market for the period 2017 – 2027, wherein 2018 is the base year and 2019 to 2027 is the forecast period. Data for 2017 has been included as historical information

- In this report, we analyze the challenges industries face in acquiring the right reciprocating compressor that can cope with the rapidly changing world. The report also highlights the total revenue generated through the sale of reciprocating compressors and provides detailed insights about volume of different types of reciprocating compressors across various key regions worldwide.

North America Reciprocating Compressor Market: Snapshot

- North America is seen as the growth hub for new technology driven enterprise business models. North America is experiencing large-scale infrastructure investment and economic development which is expected to boost the demand for reciprocating compressors.

- The U.S. has largest oil production capacity in North America. Growth in the number of industrial infrastructure projects, and increasing investment across all process industries such as petrochemicals, oil & gas, and pharmaceuticals is expected to propel growth of the reciprocating compressor market across numerous industry verticals in the region.

Key Growth Drivers of Reciprocating Compressor Market

- Rising adoption of reciprocating compressors in iron and steel production processes – The steel industry has been witnessing significant increase in production capacity over the last decade due to a rise in the demand for steel from developing countries across the globe. In the iron and steel industry, reciprocating compressors are utilized to deliver gases, such as oxygen and hydrogen, at high pressure.

- In the iron & steel industry, a large amount of oxygen is required for blast furnace operations or for electric arc furnaces. Hydrogen is also important in steel manufacturing, as it is used in surface processing. Therefore, demand for reciprocating compressors is expected to increase during the forecast period in order to cater to the demand for gases in the iron & steel industry, thus propelling the overall sales of the reciprocating compressor market across the globe.

- Increase in demand from refinery and LNG & CNG transport & storage plants – Demand for environment-friendly natural gas as a fossil fuel is rising consistently, as it reduces global carbon dioxide emissions by about 30%. Therefore, a rise in demand to transport LNG and CNG to onshore and off-shore (marine) is expected to boost the reciprocating compressor market.

Key Challenges for Reciprocating Compressor Market Players

- Cost of installation of reciprocating compressors is significantly high. Moreover, the cost continues to rise owing to the maintenance of hardware components such as crankshaft, connecting rod, crosshead, piston rod, piston and their rings, packing rings or seal rings, check valves, suction unloader, and clearance pocket. This factor is likely to hamper the global reciprocating compressor market during the forecast period.

- The global reciprocating compressor market is influenced by large size of the reciprocating compressor compared to other compressors such as centrifugal and screw compressors. Hence, majority of small-scale industries and lower-end applications such as food & beverages and textiles prefer other cost-effective compressors due to the size factor.

Reciprocating Compressor Market: Competition Landscape

- In April 2019, Kobe Steel, Ltd. established a 40 MW test facility for large-capacity nonstandard compressors in western Japan

- In March 2019, Atlas Copco AB acquired Quincy Compressor LLC from EnPro Industries, a U.S.-based air compressor manufacturer, to develop the Quincy brand independently and establish a brand portfolio strategy

Reciprocating Compressor Market: Company Profiles

- Kobe Steel, Ltd.: Incorporated in 1905, Kobe Steel, Ltd. is based in Tokyo, Japan. The company manufactures iron & steel and also supplies copper and aluminum products across the globe. It has its operating offices in the U.S, Europe, and Asia. In 1914, Kobe Steel developed its first air compressor. The company provides oil-free compressors with highest specs, compressors for LNG-fuelled ships, and HVAC compressors for hydrogen refueling stations.

- Hitachi Ltd.: Hitachi Ltd. is a diversified company with many business segments which include construction machinery, social infrastructure & industrial systems, automotive system, electronic systems & equipment, information & telecommunication systems, high functional materials & components, smart life & ecofriendly systems, and others. The company is engaged in offering a complete line of reciprocating compressors across the globe.

- Other major players operating in the global reciprocating compressor market and profiled in the report include

- Atlas Copco

- Burckhardt Compression AG

- Siemens AG

- GE Company

- IHI Corporation, Ltd.

- Mitsui E&S Holdings Co., Ltd.

- The Japan Steel Works, LTD.

- Kaeser Kompressoren Co., Ltd.

- Mayekawa Mfg. Co., LTD

- Mikuni Kikai Kogyo Co., LTD.

- Gardner Denver Holdings Inc.

- Howden Group Ltd.

- Ariel Corporation.

- Companies are shifting toward advanced equipment, integrating new technology to enhance reciprocating compressor life time, and reduce size and maintenance cost to gain a competitive advantage in the reciprocating compressor market apart from maintaining their position in the market.

Read Our Latest Press Release:

About Us

Transparency Market Research is a next-generation market intelligence provider, offering fact-based solutions to business leaders, consultants, and strategy professionals.

Our reports are single-point solutions for businesses to grow, evolve, and mature. Our real-time data collection methods along with ability to track more than one million high growth niche products are aligned with your aims. The detailed and proprietary statistical models used by our analysts offer insights for making right decision in the shortest span of time. For organizations that require specific but comprehensive information we offer customized solutions through ad-hoc reports. These requests are delivered with the perfect combination of right sense of fact-oriented problem solving methodologies and leveraging existing data repositories.

Contact

Transparency Market Research State Tower,

90 State Street,

Suite 700,

Albany NY – 12207

United States

USA – Canada Toll Free: 866-552-3453

Email: [email protected]