Outstanding De-foaming Performance of Anti-wear Phosphate-esters Drive Market Demand

Eco-friendly anti-wear lubricant additives are gaining the attention of manufacturers in the North America acid phosphates market. Hence, manufacturers are increasing their production capacities to develop sustainable phosphate-esters with excellent de-foaming attributes. For instance, global leader in advanced materials and specialty chemicals Solvay, has a rich product portfolio in acid phosphates such as their product Lubrhophos® LF800 that offers anti-wear performance and staining inhibition in metalworking formulations. As such, the revenue of lubricant additive application segment is projected to experience an uptick and the North America acid phosphates market is expected to be valued at ~US$ 256 Mn by the end of 2027.

In order to bolster their credibility in the global landscape, manufacturers are developing non eco-toxic and readily biodegradable phosphate-esters with anti-corrosion attributes. These novel esters are pervasively replacing cetyl oleyl phosphate esters, owing to their outstanding emulsion stability and limited soap formation in hard water. Thus, good anti-wear and de-foaming performance have become the key focus points for companies in the market landscape.

To gauge the scope of customization in our reports Ask for a Sample

Prioritizing Investments in R&D Activities Leads to Sustainable Innovations in Lubricants

Since the revenue of lubricant additives is anticipated for exponential growth, companies in the North America acid phosphates market are increasing their R&D capabilities to introduce new ways of sustainable chemistry. For instance, the specialist in performance additives for lubricants, Italmatch Chemicals, is increasing its research activities in specialty chemicals to develop sustainable lubricants. Manufacturers are prioritizing their investment in R&D capabilities that cover all aspects of organic and inorganic synthesis. They are focusing on performance testing of new as well as existing lubricant products that are suitable for final applications.

A global and flexible manufacturing footprint has become one of the key success factors for companies in the North America acid phosphates market. Apart from Europe and Asia Pacific, companies are increasing efforts to produce diversified batch chemistries at different plants in the U.S. This explains why the revenue in terms of application is higher in the U.S. as compared to Canada in the market landscape.

Zinc Phosphating Overcomes Corrosion-related Issues in Mg Alloys in Automotive Applications

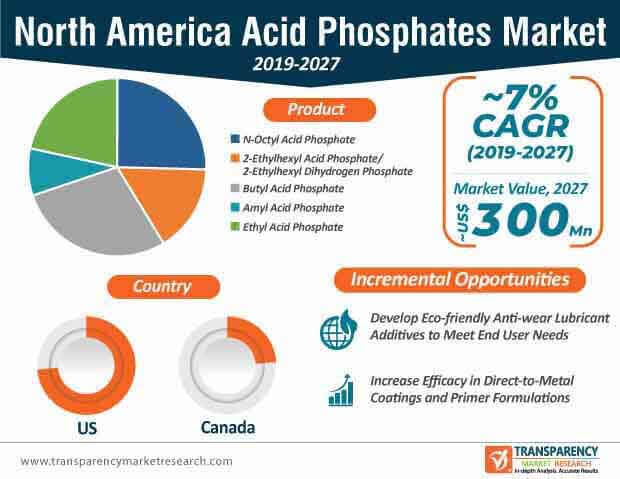

The North America acid phosphates market is expected to witness a robust growth of ~7% during the forecast period. Moreover, the paints & coatings application segment is expected to grow aggressively in the coming years. Hence, companies are tapping into value-grab opportunities in automotive applications.

Get an idea about the offerings of our report from Report Brochure

The ever-evolving automotive industry has raised a demand for high-performance coatings for the surface protection of magnesium (Mg) alloys in automotive components. However, corrosion-related issues pose a challenge for manufacturers and the market. Hence, manufacturers in the North America acid phosphates market are innovating in non-chromate chemical conversion coatings such as phosphate and stannate coatings to achieve high levels of corrosion protection.

One of the widely used methods for pretreatment in automotive industries is zinc (Zn) phosphating, as this solution is acidic in nature, which helps to dissolve Mg parts on entering pretreatment baths. This novel solution is increasingly replacing chromium-based conversion coatings.

Innovations in Adhesion Promoters Lead to Development of Direct-to-Metal Coatings

Apart from lubricant additives and coatings, manufacturers in the North America acid phosphates market are exploring incrementing opportunities with drilling muds, since their revenue is anticipated to exponentially during the forecast period. As such, the market is estimated to reach an output of ~33,200 tons by the end of 2027. On the other hand, manufacturers in the North America acid phosphates market are increasing their production capacities to develop phosphate esters, as novel esters are also being used as adhesion promoters. For instance, Lubrizol— a key supplier of specialty chemicals for industrial and consumer markets, is involved with the development of phosphate esters used as adhesion promoters for water-borne and solvent-borne coatings to ferrous metal, zinc alloys, and aluminum substrates.

Companies in the North America acid phosphates market are directing their investments toward corrosion inhibitor technologies that deploy corrosion protection to metal and zinc alloys. This has led to increased availability of direct-to-metal coatings and high-performance primer formulations.

Looking for Regional Analysis or Competitive Landscape in North America Acid Phosphates Market , ask for a customized report

Analysts’ Viewpoint

The North America acid phosphates market is competitive and largely consolidated with tier 1 companies comprising major players dictating ~30%-45% of the market share. Prioritizing investment in R&D activities is one of the key takeaways, which will be an important deciding factor of a company’s success in the next decade.

The demand for acid phosphates is increasing due to the rising demand for high-performance coatings for Mg alloys. However, corrosion-related issues pose a restraint for market growth. Hence, manufacturers should increase the availability of zinc phosphating formulations that are useful in pretreatment baths in order to achieve corrosion protection for automotive components.

North America Acid Phosphates Market: Overview

- In terms of value, the acid phosphates market in North America is expected to reach ~US$ 256 Mn by 2027

- Acid phosphates are organic compounds that when mixed with carefully selected additives form a group of synthetic fluids, which can be used as flame retardants. N-Butyl acid phosphate has several industrial uses. It can be used as an esterification catalyst and catalyst in coatings, textile lubricants, polymerizing agents, and corrosion inhibitors. Amyl acid phosphate can be used as an antistatic agent in textile production and as an acid catalyst in coatings.

- Oil and gas exploration and drilling activities in North America are growing at a rapid pace. According to BP Statistical Review, the region was the second-largest producer of oil and the largest producer of gas in the world in 2018.

North America Acid Phosphates Market: Key Drivers and Restraints

- According to the World Oil, in the U.S., around 27,000 wells were drilled in 2018, while around 24,000 wells were drilled in 2017. However, the number of wells drilled in Canada declined slightly in 2018 over that in 2017. In Canada, around 7,200 wells were drilled in 2017, while around 7,000 wells were drilled in 2018.

- Thus, rise in oil and gas exploration and drilling activities in North America is anticipated to drive the demand for drilling mud in the near future. This, in turn, is expected to boost the acid phosphates market in the region during the forecast period.

- All engine oils and lubricants need to deliver high performance throughout the operating life of an engine or machine. Hence, manufacturers of engine oils and lubricants use lubricating additives to attain anti-wear and anti-corrosive properties.

- Thus, increasing demand for lubricants is projected to drive the North America acid phosphates market during the forecast period

More Trending Reports by Transparency Market Research –https://www.prnewswire.com/news-releases/wire–cable-plastics-market-insulates-growth-with-5-cagr-to-reach-a-valuation-of-us-15-bn-by-2027-transparency-market-research-301015184.html

North America Acid Phosphates Market: Key Product Segments

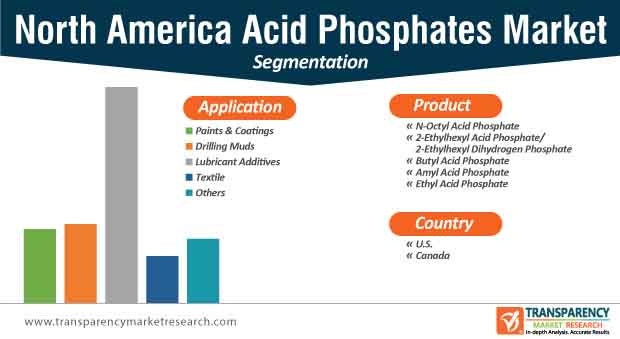

- Based on product, the acid phosphates market in North America has been segregated into N-octyl acid phosphate, 2-ethylhexyl acid phosphate/2-ethylhexyl dihydrogen phosphate, butyl acid phosphate, amyl acid phosphate, and ethyl acid phosphate

- In terms of volume, the butyl acid phosphate segment held a major share of the North America acid phosphates market in 2018. Butyl acid phosphate is an odorless solvent and, generally, it is used as a component of aircraft hydraulics and brake fluids. Since it is an odorless solvent, it can be used as an anti-foaming agent in detergents, paints, and adhesives. Commercial uses of butyl acid phosphate include adhesives and sealants, inks, toners, and colorant products.

- N-octyl acid phosphate is a colorless, transparent, and oily liquid, which is widely used as a processing solvent. It possesses low volatility and a good extraction distribution coefficient. It can function as a catalyst and an additive also. It is employed as a curing agent in paints and coatings.

North America Acid Phosphates Market: Key Applications

- Based on application, the acid phosphates market in North America has been divided into paints & coatings, drilling muds, lubricant additives, textile, and others

- Demand for amyl acid phosphate and N-octyl acid phosphate for use in lubricants in North America is expected to rise in the near future, owing to corrosion and wear resistance properties of these phosphates. Wear is the most common cause of material replacement. In order to deal with this issue, acid phosphates are added, as they can act as corrosion inhibitors.

- Rise in the demand for fire safety in commercial products is expected to fuel the demand for acid phosphates for use in drilling and lubricating additives in the near future

- In aviation hydraulic systems, acid phosphates are employed in lubricants used in aircraft in order to maintain the system temperature constant

Request for covid19 Impact Analysis – https://www.transparencymarketresearch.com/sample/sample.php?flag=covid19&rep_id=76731

U.S. to be a Highly Lucrative Region of North America Acid Phosphates Market

- Recovering prices, high demand from the aerospace industry, and advancements in activities for oil and gas exploration and production are boosting the demand for lubricant additives in the U.S. This, in turn, is fueling the acid phosphates market in the U.S., as butyl and ethyl acid phosphates are largely used in lubricant additives.

- Acid phosphates present a major class of commercial additives used as flame retardants, hydraulic fluids, plasticizers, solvents, extraction agents, adhesives, antifoaming agents, and coatings. Growth of various end-use industries in Canada is expected to drive the demand acid phosphates for use in several applications in the country in the near future.

North America Acid Phosphates Market: Competition Landscape

- Major manufacturers of acid phosphates include

- Solvay

- Kao Corporation

- Lanxess, and Lubrizol Corporation

- Alfa Aesar,

- IsleChem, LLC.

- These companies have considerable presence across the globe.

- Major players focus on developing commercially viable processes for the manufacture of products, which comply with the regulations