Ironless Linear Motors Gain Prominence in Automation Engineering and Production Sectors

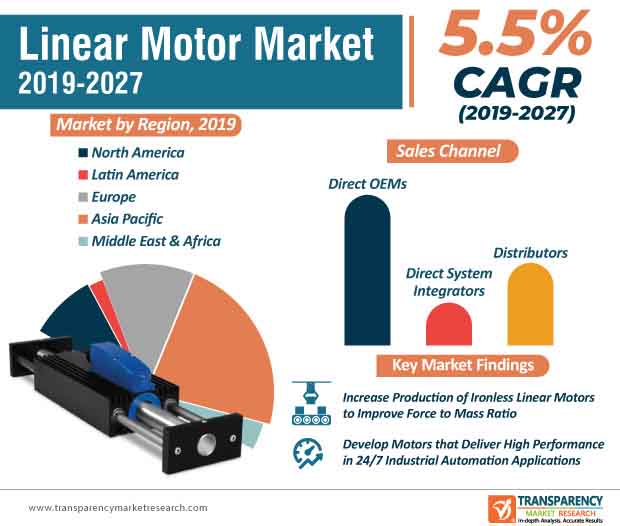

Ironless linear motors are being increasingly used to improve force to mass ratio in various end-case applications. Hence, manufacturers are increasing their research efforts to develop lightweight linear motors that enhance productivity in various applications. As such, the semiconductor application segment is estimated to lead the linear motor market, whereas the global market is expected to reach a value of ~US$ 2 Bn by the end of 2027. Hence, companies are increasing their production capacities to manufacture ironless linear motors that are more dynamic and support precise handling of small masses.

Manufacturers in the linear motor market are tapping into opportunities in sectors such as automation engineering and production to generate revenue streams. For instance, Schaeffler Group-a German manufacturer of rolling element bearings for automotive and industrial uses, announced the launch of their new UPLplus linear motor series, which are gaining popularity in automation engineering and production sectors. On the other hand, ironless motors are being used in innovative applications such as analytics in medical technology as well as in inspection machines in productronics.

Request a sample to get extensive insights into the Linear Motor Market

Cutting-edge Linear Motor Stages Support Long Travel in Terms of Nanometer Resolution

High accuracy, repeatability, and functionality are important attributes that are becoming increasingly commonplace in the linear motor market. Hence, manufacturers are increasing R&D to integrate absolute-measuring linear position encoders in motors that support long travel in terms of nanometer resolution. For instance, Physik Instrumente— a supplier of solutions in the fields of motion and positioning, has gained expertise in the development of high-accuracy linear motor stages that help end users achieve high velocities in direct drive ironless linear servo motors.

To understand how our report can bring difference to your business strategy, Ask for a brochure

There is a growing demand for high performance connectors that provide special protection from contamination in 24/7 industrial automation applications. Hence, companies in the linear motor market are bolstering their credibility by offering increased toughness and reliability in innovative linear motor stages. On the other hand, manufacturers are increasing their efficacy in the production of electrodynamic linear motors integrated with cutting-edge linear motor stages. These production practices support high load capacities whilst eliminating cage migration issues.

Awareness about Critical Rotation Speeds Helps Overcome Limitations in Motor Shafts

Manufacturers in the linear motor market are increasing efforts to gain competitive edge over the other by designing cost-effective machines or by increasing the availability of machines that generate higher output. However, limitations in motor shafts, stemming from windup twist under heavy load and acceleration pose as a restraint for manufacturers. This explains why the linear motor market is expected to expand at a modest CAGR of ~5.5% throughout the forecast period. Hence, manufacturers need to be more aware about critical rotation speeds and length limitations.

On the other hand, mechanical drive restrictions are being overcome by using linear motors. As such, linear motors are being highly publicized in machine tool applications. This is evident since machine tool applications involving metal forming and metal cutting are estimated to dominate the third-highest revenue in the market landscape. The electromagnetic force in linear motors eliminates the need for mechanical connection, thus eliminating any mechanical hysteresis or pitch-cycle error.

Companies Generate Incremental Opportunities with High Adoption of Direct Drive Motors

Linear motors play a pivotal role for engineers while developing new platforms for machine tools. Thus, direct drive motors involving torque and linear motors are increasingly being adopted in industry practice. As such, linear motors are being perceived as high-end alternatives to gearboxes and ball screws. New trends such as increasing force density in direct drive motors are some of the key drivers contributing to the growth of the linear motor market. This explains why the market is estimated for an output of ~1,800 units by the end of 2027.

Companies in the linear motor market are increasing their production capabilities to increase the availability of motors that accommodate in various size options in direct drive motors. Since direct drive tools are a key component in machine tools, manufacturers are focusing on performance and product quality to support the tool-turning power profile within a certain volume.