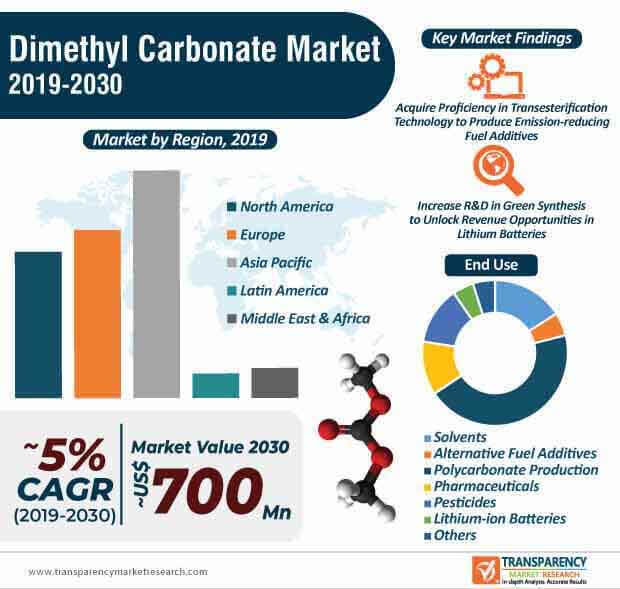

Transesterification Technology Instrumental in Production of Emission-reducing Fuel Additives

Organic carbonates are gaining increased applicability in various chemical and biotechnical processes, owing to their advantageous attributes. Likewise, dimethyl carbonate is being highly publicized for its versatile chemical reactivity in the production of alternate fuel additives and cleaning agents. Manufacturers in the dimethyl carbonate market are grabbing incremental opportunities by increasing the applicability of DMC as a solvent in the synthesis of polymers, flavoring agents, and pesticides, among others. Moreover, DMC is being used as an electrolyte in lithium-ion batteries, owing to its low toxicity and efficient dissolving abilities.

Companies in the dimethyl carbonate market are increasing their research efforts to innovate in new synthesis technologies. As such, the transesterification of propylene carbonate and methanol to produce dimethyl carbonate is emerging as a mature technology. This technique is playing an instrumental role in the production of fuel additives that help to reduce vehicle emissions, thus preventing the risks of health issues among individuals.

High Demand for DMC in China for Polycarbonate Production Boosts Dimethyl Carbonate Market Growth

Dimethyl carbonate is becoming an important chemical raw material, owing to its good biodegradability, polarity, and reactivity, which is being channelized in the production of polycarbonates, fuel additives, and cleaning solvents. New synthesis technologies such as the synthesis of dimethyl carbonate from urea and methanol is becoming popular recently. Companies in the dimethyl carbonate market are unlocking revenue opportunities with rapid advancements in polycarbonate production and lithium batteries in China. The high demand for DMC in polycarbonate production and lithium batteries is expected to bolster growth of the global dimethyl carbonate market.

More Trending Reports by TMR:

The synthesis of DMC via transesterification of propylene carbonate and methanol holds promising potentials for the production of paints and coatings, owing to its advantages of less waste generation and less equipment corrosion. As such, manufacturers are increasing efforts to develop highly efficient solid catalysts and are increasing focus in new three-phase catalytic distillation technologies. They are innovating in new methods for DMC separation from DMC-methanol azeotrope with low energy consumption.

Buy Now:

https://www.transparencymarketresearch.com/checkout.php?rep_id=8245<ype=S

Green Synthesis of Dimethyl Carbonate Gains Popularity as Cost-efficient Method

Carbon is an abundant element and is one of the key elements in fuels and polymers. This has encouraged companies in the dimethyl carbonate market to convert carbon dioxide (CO2) into useful chemicals such as dimethyl carbonate (DMC), owing to the non-toxic attributes of carbon. This trend is anticipated to grow, since traditional processes such as phosgenation involve drawbacks such as the use of highly toxic and corrosive phosgene gas and the formation of large amounts of inorganic salts. Hence, companies in the dimethyl carbonate market are increasing their R&D efforts to gain efficacy in the green synthesis of DMC.

Manufacturers are adopting methods that involve direct synthesis of dimethyl carbonate from CO2 and methanol in order to gain efficacy in green chemistry. As such, green synthesis of DMC is growing popular as a cost efficient method, since methanol is a less expensive raw material. As such, DMC is being used as a precursor for polycarbonate synthesis.

Request Brochure:

Request Brochure: