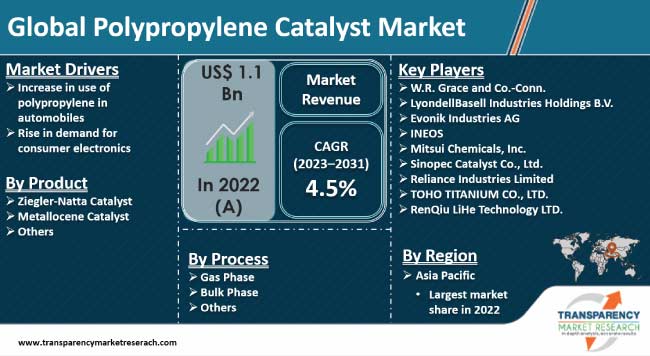

The global polypropylene catalyst market was valued at around US$ 1 Bn in 2017 and is anticipated to expand at a CAGR of more than 4% from 2018 to 2026, according to a new report by Transparency Market Research (TMR) titled ‘Polypropylene Catalyst Market: Global Industry Analysis, Size, Share, Growth, Trends, and Forecast, 2018–2026.’

Request Brochure:

https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=38747

Rise in Requirement for Specialty Grades of Polypropylene

Polypropylene catalyst has the ability to help in obtaining different configurations of polypropylene. Various important parameters controlled by polypropylene catalyst include c-monomer distribution, stereo-specificity, degree of linearity, etc. Leading companies operating in end-user industries of the polypropylene catalyst market value chain depend on specialty grades which are sometimes further enhanced to suit their requirements. High-grade polypropylene is required in polypropylene thermoplastic composites which are used in automotive interior parts including trim, main, and auxiliary instrument panels and door panels and columns. The requirement for high-grade polypropylene provides immense opportunities to manufacturers of polypropylene catalysts to supply a product that provides polypropylene with improved toughness, thickness, and other essential characteristics.

Enquiry Before Buying:

https://www.transparencymarketresearch.com/sample/sample.php?flag=EB&rep_id=38747

Difficulties faced by Polypropylene Producers in adopting the New Catalyst anticipated to hinder Market

Polypropylene catalyst plays a key role in defining properties of produced polypropylene. The requirement for polypropylene properties changes in accordance with the end-use. The series of developments observed in the polypropylene catalyst market is very interesting from the research perspective; however, from the cost perspective, these developments have made it difficult for commercial producers of polypropylene to change their catalyst. Though polypropylene producers are not required to make changes in their automation, machines need to be cleaned and reconfigured every time when a new type of catalyst comes in picture. This may take several days. The downtime may cause loss of productivity and increase in the cost of reconfiguration. The new catalyst has to be tested by the polypropylene producer for cost calculation and needs to be checked for properties defined by the consumer for the specific polypropylene required.

Buy Now:

https://www.transparencymarketresearch.com/checkout.php?rep_id=38747<ype=S

Ziegler–Natta Catalyst anticipated to be a Dominant Segment of the Global Polypropylene Catalyst Market

Ziegler–Natta catalyst is the most widely used polypropylene catalyst, which polymerizes propylene into polypropylene in a fluidized bed reactor. The demand for Ziegler–Natta catalyst is expected to increase during the forecast period, due to its lower cost compared to metallocene catalyst. Manufacturers such as Clariant have developed Ziegler–Natta catalysts that demonstrate improved technical and commercial features.

Gas Phase expected to be a Leading Process Segment of the Global Polypropylene Catalyst Market

Dominance of the gas phase process segment in the global polypropylene catalyst market can be ascribed to effectiveness of the gas phase process in terms of supply of monomers and removal of reaction heat. Also, the gas phase process eliminates the need to remove or replace the catalyst after every reaction. However, use of the bulk phase process yields the catalyst in high amounts.

Injection-molded Products held a Major Share of the Global Polypropylene Catalyst Market

Among applications, the injection-molded products segment dominated the global polypropylene catalyst market and is expected to continue its dominance in the next few years. The rising consumption of injection-molded products is attributable to high demand from automotive and transportation industries. Also, the rising demand for composites, which significantly use polypropylene as a base material, is projected to boost the polypropylene catalyst market during the forecast period.

Asia Pacific held a Major Share in 2017

Asia Pacific dominated the global polypropylene catalyst market in 2017, owing to high demand for polypropylene catalyst in the region. This is because Asia Pacific is a major manufacturer of polypropylene across the globe. Major manufacturers of polypropylene catalyst such as LyondellBasell Industries Holdings B.V. and Mitsui Chemicals, Inc. operate their polypropylene catalyst manufacturing facilities in Asia Pacific. In countries such as South Korea, manufacturers of polypropylene catalyst are expanding their manufacturing facilities, due to increased demand for polypropylene from automobile and home appliance applications. The volatility in prices of crude oil has reflected in the production of polypropylene and polypropylene catalyst in the last few years. Furthermore, consumption of polypropylene catalyst in GCC is likely to increase in the near future, due to increase in the polypropylene production by three major companies in Middle East & Africa: Borouge, Sadara Chemical Company, and Oman Oil Refineries & Petroleum Industries Company (ORPIC).