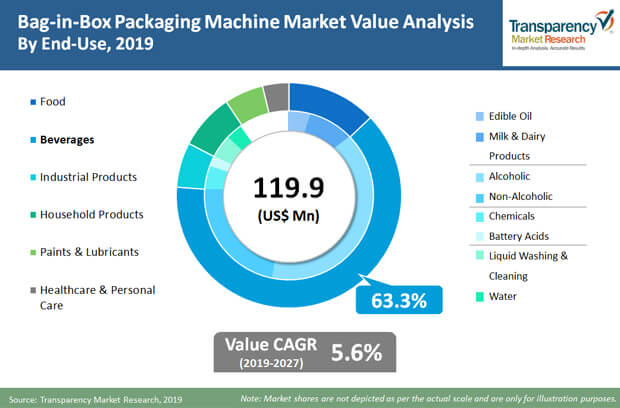

Transparency Market Research provides key insights on the bag-in-box packaging machine market in the report, titled “Global Bag-in-box Packaging Machine Market: Industry Analysis and Opportunity Assessment, 2019–2027.” In terms of value, the global bag-in-box packaging machine market is estimated to register a CAGR of 5.6% during 2019-2027, owing to various factors. In this report TMR delivers detailed insights.

The report includes a market research study on the global bag-in-box packaging machine market, which includes trend analysis and market assessment of filling technologies such as aseptic and non-aseptic.

Want to know the obstructions to your company’s growth in future? Request a brochure @ https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=66326

Automatic bag-in-box packaging machines are linked together with control systems to form a complete line with automation to manufacture bag-in-box containers at a faster rate. Semi-automatic bag-in-box packaging machines are preferred by many bag-in-box manufacturers as they are best suitable for limited production. Bag making machine, bag filler, cartoner, and bag inserters are available in semi-automatic mode.

By machine type, the bag-in-box packaging machine market is segmented as standalone and integrated. Standalone bag-in-box packaging machines account for the highest share. Standalone are either automatic or semi-automatic machines, which form a bag-in-box packaging machine line without depending on other machinery. An integrated bag-in-box packaging machine consists of a single packaging line, where all operations are linked with simulation software or control systems. The integrated bag-in-box packaging machine system performs all operations such as the forming of the bag, filling, cartoning, case erectors, and bag inserters & sealers.

Europe has the highest wine-drinking population and most of the wine manufacturers are packaging their wines in bag-in-box formats. Bag-in-box packaging formats provide for more diverse choices in terms of price, convenience, and quality than the traditional bottles. The automated bag-in-box packaging machine market in developed in countries such as the US, Germany, France, the UK, and Italy is matured, and is expected to witness low to moderate growth during the forecast period. Automated bag-in-box packaging machines are mostly used for higher production and efficiency. End-uses of bag-in-box packaging machine solutions include food, beverages, industrial products, household products, paints & lubricants, and healthcare & personal care. The semi-automated bag-in-box packaging machine segment is estimated to have accounted for the highest market share in terms of both value and volume in 2018.

The Europe bag-in-box packaging machine market is estimated to register a CAGR of 5.1% during the forecast period. There has been a high demand for automation in bag-in-box packaging machines in order to achieve greater level of functionality, safer handling, and productivity. Machine manufacturers in Europe are focusing on aseptic filling technology in the bag-in-box packaging machine to aid end users with increased shelf life of the product.

Most of the local beverage manufacturers in the parts of Europe use a semi-automatic bag-in-box packaging machine for limited production. The move from semi-automatic bag-in-box packaging machines to fully-automated bag-in-box packaging machine solutions means increased levels of automation such as machine vision, safety control, and even remote monitoring. All these factors are expected to influence the demand for bag-in-box packaging machines in the European region. Pattyn Packaging, a Belgian bag-in-box packaging machine manufacturer balances its performance and cost on the basis of PC control technology. The company manufactures fully automatic bag-in-box packaging machines for the packaging of products including food, oil, grease, and liquid sugar which are packed hygienically using bag-in-box packaging.

The Asia Pacific bag-in-box packaging machine market signifies the highest CAGR in terms of value. The Asia Pacific bag-in-box packaging machine market is estimated to register a CAGR of 7.0% over the forecast period. The packaging machinery industry in Asia has been rapidly upgrading due to industrialization and urbanization. This has attracted many manufacturers and brand owners to establish their market in the merging countries of Asia such as China, India, and Malaysia. The India bag-in-box packaging machine market is expected to witness the highest growth during the forecast period, owing to the increasing demand for quality products.

Purchase Premium Research Report @ https://www.transparencymarketresearch.com/checkout.php?rep_id=66326<ype=S

The aseptic bag-in-box technology in Asia was developed more than 25 years ago to cater to the needs of the food and beverage industry to provide extended shelf life. Aseptic filling technology secures the transfer of processed ingredients, especially sensitive products with neutral PH areas such as milk. The aseptic packaging business in Asia has increased from 19% to 27% in the past five years. Bag-in-box applications are increasingly including foodservices, restaurants, catering, and coffee dispensing machines. B2B use such as beverage and fruit processing, is the largest segment in the aseptic bag-in-box market.

Key companies functioning in the global bag-in-box packaging machine market are Smurfit Kappa Group, DS Smith Packaging Ltd., Bosch Packaging Technology GmbH, Triangle Package Machinery Co., ABCO Automation, Inc, Rovema GmbH, IC Filling Systems, Sacmi Imola S.C, Voran Maschinen GmbH, TORR Industries, Kreuzmayr Maschinenbau GmbH, Flexifill Ltd, Terlet BV, and Gossamer Packaging Machinery.

Read Our Trending Press Release Below: https://www.prnewswire.com/news-releases/development-of-solutions-in-telecom-api-market-to-act-as-enabler-for-integration-of-services-with-mobile-internet-and-cloud-leading-the-way-tmr-301180473.html