Global Form-fill-seal Machines Market – An Overview

On a steady growth curve over the period of 2019 to 2027, the Global Form-fill-seal Machines Market will see emergence of new and lucrative growth opportunities in its landscape. And, an active and aggressive vendor landscape would also contribute significantly to the growth projected for the market. Besides, the robust growth rate would also help the Global Form-fill-seal Machines Market reach a higher valuation.

Some of the notable trends, drivers and developments are detailed out below:

- Demand for packaged and processed food is seeing an upward curve owing to a number of factors such as hectic work schedules that drain the will for cooking and increase the need for products with longer shelf life, and growing demand for ready to eat foods. Besides, as more and more people eat out and look for convenient food packaging, demand for Global Form-fill-seal Machines will grow.

- Demand for consumer goods and pharmaceuticals is growing rapidly due to increase in disposable income and rapidly ageing population, respectively. This contributes massively to the growth of Global Form-fill-seal Machines Market over the forecast period. This is a major outcome for need of blisters being high in these industries for packaging purposes.

Planning to lay down future strategy? Perfect your plan with our report brochure here https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=22664

Shifting Consumer Preference Towards Flexible Packaging to Drive the Growth of the Vertical Form-Fill-Seal Machines Market Segment

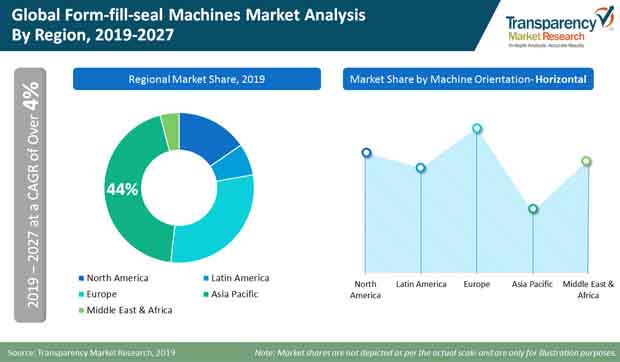

The global form-fill-seal machines market is estimated to be valued at approximately US$ 10,031 million in 2019. The market is projected to expand at a CAGR of more than 4% during the forecast period of 2019-2027.

Form-fill-seal machines for thermoformed rigid packaging products, also known as thermoform-fill-seal machines are used for the packaging of food and other consumer products across the globe. Cups and trays for packaging of food products are majorly produced with thermoform-fill-seal machines. Due to the relatively high price of thermoform-fill-seal machines as compared to form-fill-seal machines for flow wraps, small food processing firms are reluctant towards using thermoform-fill-seal machines. On the contrary, because they offer better aesthetics and high protection for semi-solid food items, thermoformed plastic cups have high adoption among large food and beverage companies.

Packaging formats suitable with thermoform-fill-seal machines include, not only cups and trays, but also blisters. The adoption of blister packaging solutions is not limited to the pharmaceutical industry, but also by various consumer goods and packaged food companies. The rising preference among consumers for unit dose packaging solutions has driven the adoption of blister packaging solutions for multiple consumer goods.

Bottles (including vials) and ampoules produced on blow-fill-seal machines are highly preferred in the pharmaceutical industry. The adoption of form-fill-seal machines for beverage packaging is rapidly growing. The average selling price of form-fill-seal machines for production of bottles and ampoules is very high as majority of these machines are produced considering the strict pharmaceutical industry regulations and standards. Thus, large number of beverage and pharmaceutical companies prefer premade bottles and vials for packaging over adoption of form-fill-seal machines.

Looking for exclusive market insights from business experts? Request a Custom Report here https://www.transparencymarketresearch.com/sample/sample.php?flag=CR&rep_id=22664

Blow-fill-seal and thermoform-fill-seal are two of the packaging machines falling under the family of form-fill-seal machines. Blow-fill-seal and thermoform-fill-seal machines are horizontal form-fill-seal machines and cost comparatively higher than vertical form-fill-seal machines. This has resulted into around 80% market share in terms of value of the horizontal form-fill-seal machines segment in 2019, which is projected to drop slightly by the end of 2027.

Consumers are readily advancing towards flexible packaging solutions, impacting the growth of segments such as bottles & ampoules, cups & trays, and blisters. On the other hand, the demand for vertical form-fill-seal machines is propelled by the consumer preference for flexible packaging solutions such as bags and pouches. Leading vertical form-fill-seal machine manufactures are making efforts for evolving the packaging design for flexible packaging formats using form-fill-seal machines. The cups & trays segment is expected to register the highest growth rate among all packaging type segments of form-fill-seal machines while the bags & pouches segment is projected to create the most lucrative potential for the form-fill-seal machines market across the globe.

Intolerance towards conventional plastic materials is one of the major factors impacting the global demand for form-fill-seal machines, as form-fill-seal machines are specifically suitable for the production of plastic packaging formats, rigid as well flexible. Vertical form-fill-seal machines require heat sealable plastic materials while blow-fill-seal and thermoform-fill-seal machines require heat moldable plastic materials. Thus, end-users are adopting alternate packaging materials such as paper, impacting the potential for form-fill-seal machines market globally.