Wafer inspection systems are required for timely detection of physical and technological defects present within wafers. Currently, both e-beam and optical technologies are used in the detection of defects in wafers. With the application of e-beams manufacturers of compact devices are able to timely detect faults in wafers, thus saving the additional expenditure, which otherwise they would incur on re-inspection. The technology therefore ensures long-term usage of wafers across various industrial verticals. This has emerged as a key reason, positively impacting the overall trajectory of the global e-beam wafer inspection system market.

Increasing applications of thin wafers in manufacturing small or miniaturized devices used in micro-electro mechanical systems, laptops, and smartphones among others have bolstered the demand for e-beam wafer inspection system. Also the market is forecast to gain from the persistently rising activities in the semiconductor industry. These industrial activities will continue rising over the forecast period, delivering the e-beam wafer inspection system market with ample opportunities to gain from.

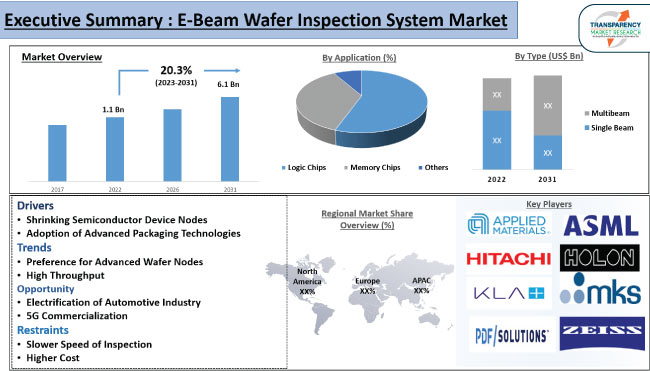

Spurred by the aforementioned factors, the global e-beam wafer inspection system market is forecast to exhibit a CAGR of 17.5% between 2015 and 2025. Rising at this rate, the market will reach US$1.06 bn by the end of 2025, from US$248.3 million in 2016.

Request for a sample:

https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=15884

Detection Imaging to Remain Dominant Segment Based on Application

Based on type, the global e-beam wafer inspection system market is segmented into less than 1 nm, 1 to 10 nm and more than 10 nm inspection resolution system. In 2016, e-beam wafer inspection system market was dominated by more than 10 nm wafer inspection systems, followed by the other two segments. However, during the forecast period the less than 1 nm segment will showcase a higher CAGR.

On the basis of application, the global e-beam wafer inspection system market has been segmented into defect imaging, lithographic qualification, bare wafer OQC/IQC, wafer dispositioning, reticle quality inspection, and inspector recipe optimization. Of these, defect imaging formed the largest application segment with a share of 38.5% in the market in 2016. It is expected to remain dominant through the course of the forecast period. Besides this, inspector recipe optimization followed by bare wafer OQC/IQC have emerged as the application segments exhibiting strong prospects for the market.

Asia Pacific Exhibits Most Lucrative Opportunities

Regionally, Asia Pacific, Europe, North America, Latin America, and the Middle East and Africa constitute the key segments in the global e-beam wafer inspection system market. Among these nations, Asia Pacific emerged dominant holding a little short of 60% share in the global market in 2016. In addition, North America and Europe have been demonstrating lucrative market opportunities over the last few years. These regions boast high investment in the research and development, which has led to extensive application of high quality wafers across diverse industries. With this, the use of e-beam wafer inspection system has also risen to detect any faults, thus giving significant impetus to the market.

Since Asia Pacific has showcased tremendous growth in the last few years, it offers lucrative opportunities for the market. Especially in emerging economies, the pace of industrialization is considerably bolstered. This has created attractive opportunities for the e-beam wafer inspection system market, as rising industrialization will mean increasing investment in miniaturization thereby boosting the scope of application for e-beam wafer inspection systems.

Some of the leading players in the global e-beam wafer inspection system market are Hitachi Ltd. (Japan), ASML Holding N.V. (Netherlands), KLA Tencor Corporation (The U.S.), Taiwan Semiconductor Manufacturing Co. Ltd. (Taiwan), NXP Semiconductors N.V. (Netherlands), Lam Research Corporation (The U.S.), Renesas Electronics Corporation (Japan), Integrated Device Technology Inc. (The U.S.), Applied Materials Inc. (The U.S.), and Synopsys Inc. (The U.S.) among others.

Ask for brochure:

https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=15884

E-Beam Wafer Inspection System Market to Observe Growth in Expansion of Semiconductor Industry

Due to the growing adoption of these inspection systems by semiconductor manufacturers for high-quality inspection, the global E-beam wafer inspection system market is likely to observe enormous growth potential. Since the semiconductor industry is rapidly expanding and pushing its development boundaries, there will be a huge demand for more wafer inspection systems during the assessment timeframe. The said market, however, is technically sophisticated and is particularly capital intensive. Hermes Microvision is regarded as one of the leading players in the global E-beam wafer inspection system market and is likely to take over the major portion of the market. The demand for wafer inspection systems is expected to rise during the prediction timeframe, as the semiconductor industry develops and expands. This growing prominence of wafer inspection systems is likely to open up new business opportunities for manufacturers, attracting new vendors and thus intensifying competition.

Market to Benefit from Increasing Demand for Consumer Electronics Sector

Steadily increasing demand for high-quality semiconductors has stemmed from augmented growth in the consumer electronics business, which includes products like LEDs, LCDS, wearables, gadgets, and smartphones. The inspection method is utilized in these systems to detect defects or faults in compact devices, which is estimated to support growth of the global E-beam wafer inspection system market in near future. Furthermore, manufacturers’ increasing investments in innovation to provide high-precision semiconductor tools at lower costs is likely to support demand from the industry. The demand for e-beam wafer inspection systems is being boosted by ongoing technological developments that are enabling semiconductor makers to use EUV lithography in their fabrication processes.

Lithography equipment is widely utilized in the processes of wafer fabrication in IC production technology and semiconductor manufacturing, which necessitates the detection of defects on the mask and wafer, resulting in a rise in the use of e-beam inspection in wafer fabrication. Manufacturers are concentrating their efforts on developing multiple e-beam inspection systems with throughput and high sensitivity by incorporating sophisticated technology like computation to cater to the high demand for EUV lithography.

Read Our Latest Press Release: