The automotive wheel market in Asia Pacific is projected to grow at a fast rate during the forecast period. However, the auto industry in India is growing at a sluggish pace due to the ongoing COVID-19 (coronavirus) pandemic. As such, car manufacturing is slowly picking pace whilst manufacturers are making efforts to inhibit the spread of coronavirus. Facility shutdowns and delayed shipments of raw materials have been common restraining factors for automobile manufacturers. Manufacturing in the Indian auto industry is gaining momentum, as companies are strictly abiding by government guidelines to ensure the safety of their workers and employees. These factors are projected to drive the automotive wheel market during the forecast period.

Request a sample to get extensive insights into the Automotive Wheel Market

Manufacturers Invest in State-of-the-art SAE- and TUV-approved Facilities

Companies in the automotive wheel market are pushing their boundaries to deploy technological innovations in components. Vossen Wheels-a manufacturer of luxury and performance forged wheels, has gained efficacy in the development of custom finish automotive wheels that are SAE- (Society of Automotive Engineers) and TUV- (Tough Utility Vehicle) approved. Companies in the automotive wheel market are increasing their production capabilities to manufacture high-end, deep-dish wheels that are joining the bandwagon of premier products.

Manufacturers are directing their investments in state-of-the-art TUV-approved facilities in order to gain global recognition in the market landscape. They are investing in brand-new machineries that offer tinted gloss black and other finishes to automotive wheels. The concept of Fine Element Analysis (FEA) is growing popular among automotive wheel manufacturers who aim to gain a competitive edge over other market players.

Development of Lightweight Automotive Wheels In Line with Fuel Emission Regulations

The decline of car weight has been an issue of central focus for automakers. Hence, companies in the automotive wheel market are increasing their research spending to innovate in alloy wheels. For instance, Rio Tinto-an Anglo-Australian multinational metal corporation, joined forces with researchers at the Arvida Research and Development Centre (ARDC), Canada, to introduce Revolution-Al™, a new high strength aluminum alloy developed to make lightweight car wheels. There is a growing need to develop stronger alloys for die cast car wheels that help reduce fuel consumption.

To understand how our report can bring difference to your business strategy, Ask for a brochure

Lightweight car wheels are in high demand to improve the safety and handling of vehicles. With the help of improved automotive wheels, manufacturers are able to meet strict industry standards of governments, pertaining to fuel emission regulations. Car manufacturers in the automotive wheel market are working closely with their customers to gain data about their experience through various trails and tests.

Automatic Alloy Wheel Surface Treatment Becomes Mainstream with Industry 4.0 Revolution

Pre-polishing and finishing of automotive alloy wheels play an instrumental role in car manufacturing. Hence, stakeholders in the automotive wheel market are extending their fine polishing services to car manufacturers. For instance, Fintek – a provider of surface finishing and superfinishing solutions, is capitalizing opportunities in the booming Industry 4.0 revolution, which is bringing a significant change in fine polishing for alloy wheels. As such, alloy wheels are estimated to dictate the highest revenue share among all wheel types in the automotive wheel market.

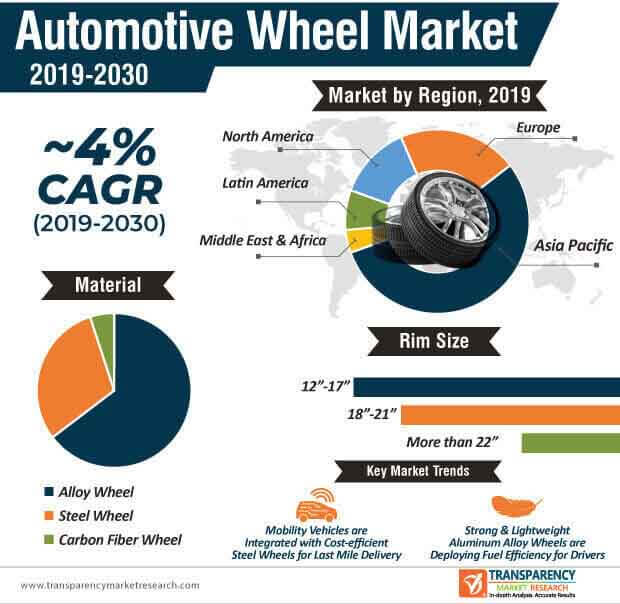

Lucrative opportunities in Industry 4.0 are creating value-grab opportunities for automotive wheel manufacturers. As such, the market is estimated to register a modest CAGR of ~4% during the forecast period. Automatic surface treatment, deburring, and polishing of wheels hold promising potentials for car manufacturers amidst the Industry 4.0 revolution.

Advanced Simulation Techniques Help Develop New Steel Grades

New materials and manufacturing technologies are delivering innovations in steel wheels. Companies in the automotive wheel market are adopting new design tools and materials such as high strength steels to innovate wheels. They are conducting static and dynamic structural analysis to develop high performance steel automotive wheels. Other manufacturing rituals include process stamping simulation and finishing practices to develop high-strength automotive wheels.

Restrictive requirements from OEMs (Original Equipment Manufacturers) and aftermarkets have compelled manufacturers to adopt a broad array of product and process simulations. For instance, Meritor Inc.- a U.S. automobile component manufacturer in Michigan, is applying its improved simulation capabilities to transform ordinary steel wheel development procedures. With the help of new manufacturing techniques, manufacturers in the automotive wheel market are able to introduce new steel grades in the market. Wheel stiffness simulation and torque simulation techniques are increasingly replacing traditional design simulation tools such as cornering fatigue test simulation.

Cost-effective and Validated Steel Wheels Create Incremental Opportunities for Manufacturers

Flow-formed rims are being highly publicized to reduce the weight of automotive wheels. Environment-friendly flow-formed rims are being used to obtain variable thickness in steel wheels. Apart from passenger vehicles, companies in the automotive wheel market are tapping into incremental opportunities in commercial vehicles that ensure last mile delivery. Maxion Wheels – a manufacturer of steel and aluminum wheels, has identified challenging requirements for new mobility applications in commercial vehicles. Manufacturers are strategizing to maximize their business for light- and medium-duty vehicles that serve last mile deliveries.

Moreover, companies in the automotive wheel market are innovating in steel wheels that are repurposed for vehicles that run on electric powertrains. Cutting-edge steel automotive wheels are meeting end user requirements for mobility in urban transport vehicles. Manufacturers are increasing their R&D muscle to develop cost-effective and validated steel wheels for mobility vehicles.

Read Our Latest Press Release: