The automotive industry has evolved at a rapid pace over the past four to five decades, owing to advancements in technology, developments in the regulatory landscape, and fluctuating consumer demands. The evolution in the automotive sector also been influenced by significant developments and advancements made in production and design aspects of different automotive components. Prior to the COVID-19 pandemic, the automotive sector around the world was witnessing a steady growth, particularly from the Asia Pacific region. At present, the evolving regulatory landscape, which predominantly focuses on introducing environment-friendly automotive technologies, has played a vital role in the development of the global automotive drive shaft market.

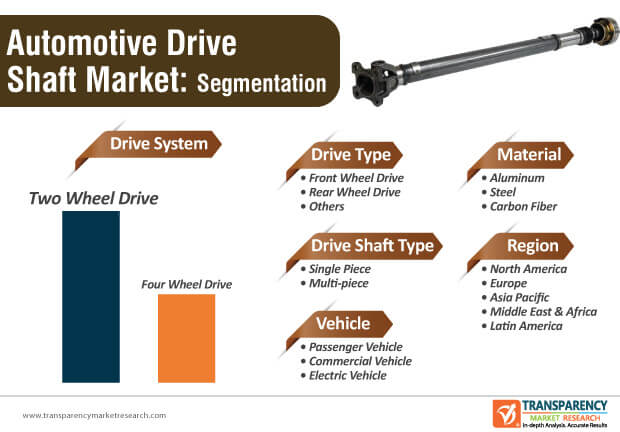

Due to the cutthroat competition across the global automotive sector, market players are increasingly focusing on rolling out energy-efficient vehicles that are adhere to the guidelines laid down to increase their share in the current market landscape. Due to increasing emphasis on energy efficiency and environment protection over the past decade, automotive manufacturers are exploring the possibilities of using automotive drive shafts made from alternative materials than steel to attain these objectives. Several lightweight materials such as aluminum and carbon fiber are increasingly being used to manufacture automotive drive shafts and the trend is likely to continue during the forecast period.

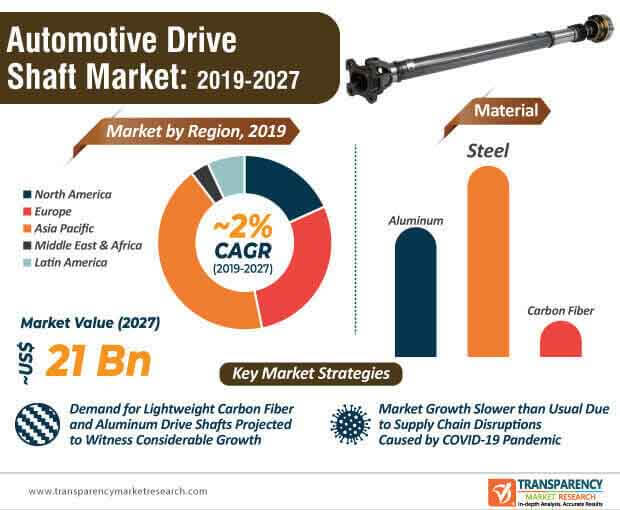

The significant rise in the sales of utility vehicles around the world is another major factor that is likely to influence the overall growth of the automotive drive shaft market in the upcoming years. At the back of these factors coupled with improvements in design and advancements in material science, the global automotive drive shaft market is expected to reach a market value of ~US$ 21 Bn by the end of 2027.

Request a sample to get extensive insights into the Automotive Drive Shaft Market

Market Players Incline toward Lightweight Carbon Fiber and Aluminum

Over the past few decades, automotive drive shafts were largely made from steel due to the exceptional durability and noise dampening properties of the material. In addition, as steel is also relatively cost-effective than other alternative materials, even in the automotive drive shaft market landscape, it continues to remain one of the most extensively used materials to produce automotive drive shafts. However, recent calls to enhance the performance and energy efficiency of automotive vehicles has compelled companies in the automotive drive shaft market to explore the possibilities of using other materials such as aluminum and carbon fiber to design and manufacture automotive drive shafts.

To understand how our report can bring difference to your business strategy, Ask for a brochure

Although steel is likely to remain the most popular material type, aluminum and carbon fiber are gaining immense popularity. Steel is tipped to remain the top choice to produce stock drive trains, as minimum maintenance is required. In recent years, the market share of aluminum automotive drive shafts has increased at a higher rate than that of steel drive shafts, and the trend is anticipated to continue in the upcoming decade. The growing popularity of aluminum automotive drive shafts can be largely attributed to the low weight of the material due to which, automotive manufacturers can optimize the efficiency and performance of their vehicles. Although the demand for aluminum automotive drive shafts is on the rise and projected to witness steady year-on-year growth, carbon fiber is likely to come out as a winner in terms of the most adopted material to produce drive shafts. Carbon fiber has emerged as one of the ideal weight-saving materials that is increasingly being used to develop automotive drive shafts. Moreover, carbon fiber is also high in durability and effective in vibration control. At present, the high cost of carbon fiber automotive drive shafts is a leading factor that is likely to hinder the demand, particularly in developing regions. However, as the cost of carbon fiber is likely to reduce as the technology matures, carbon fiber is projected to gain considerable popularity during the forecast period.

COVID-19 Pandemic Exposes Several Market Challenges, Growth Likely to Remain Sluggish in 2024

The onset of the novel COVID-19 pandemic has played a huge role in hampering the growth of the global automotive sector in 2020. As governments across the world are compelled to enforce lockdowns and an array of restrictions on trade and transportation, its effects are being felt across the global automotive drive shaft market. China is one of the most essential nations in the automotive industry and is directly or indirectly linked to ~80% of the supply chain. In the first quarter of 2020, as the core industries in China, including the automotive sector were compelled to shut down, the car sales witnessed a staggering decline.

In addition, the production of automotive vehicles has taken a major hit across the world due to lack of raw materials and large holes in the supply chain caused by the COVID-19 event. The lockdown in Hubei, which nests more than 100 automotive suppliers and other automotive hubs in the country, is another factor that is expected to play a key role in creating bottlenecks across the supply chain in the global automotive drive shaft market. While the market in China is showing signs of recovery as the majority of the automotive industry is now up and running, the global market is expected to tread through a period of uncertainty at least until the last quarter of 2020.

TMR’s Latest News Publication –