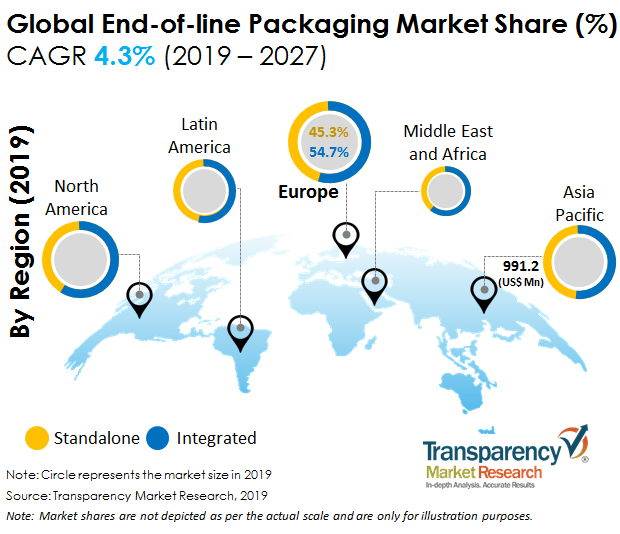

The global end-of-line packaging market was valued at US$ 4,376.3 million in 2018. The market is forecast to expand at a CAGR of 4.3% during the forecast period, 2019-2027.

An end-of-line packaging solution for an industrial unit helps to automate the entire manufacturing and packaging process. Automation of processes in machines helps increase the production quantity for any industry and aid the escalating demand. Several companies competing in the global market want to upgrade their businesses by transforming their manufacturing services for increased productivity in the long run. Industries in developing countries such as India, China, Malaysia, and Korea are implementing automated manufacturing procedures to overcome the difficulties such as shortage of labor and cost optimization. End-of-line packaging eradicates the requirement of training workers. This allows companies to engross the available labor in other valuable tasks.

Get Sample Copy:

https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=9278

Introduction of robot hands in packaging processes is rapidly becoming prevalent to surge manufacturing efficiency. Robotic systems in end-of-line packaging improve the overall production efficiency. Robotic systems in end-of-line packaging also diminish physical tasks including packaging, palletizing, and picking. A robotic arm enables augmented production efficiency that results into high investment returns and low operational costs. Robotic arms in end-of-line packaging are especially used to handle lightweight packaging as it decreases the risk of damage. The benefits of incorporating robotic arm automation in end-of-line packaging are influencing key manufacturers in various industries to install these systems.

The Automatic Technology Segment to Gain Popularity

The end-of-line packaging market is segmented on the basis of technology and the automatic segment is expected to account for the highest share during the forecast period 2019-2027. The semi-automatic segment is expected to drop its share in the overall market by the end of 2027. Automation in manufacturing facilities is gaining traction within companies to overcome the scarcity of skilled workforce, specifically in developing countries. Increased implementation of automatic production processes in production lines is expected to drive the end-of-line packaging market.

Request For Customization:

https://www.transparencymarketresearch.com/sample/sample.php?flag=CR&rep_id=9278

The Food Industry to Witness Higher Growth during the Forecast Period

On the basis of received order type, the customized order segment is expected to witness lucrative growth and is to be valued at US$ 2,907.3 Mn by 2018. End-use industries are progressively opting for customized end-of-line packaging solutions. Therefore, the share of customized order segment is expected to rise through 2027. As industries opt for standardized solutions for improved efficiency in end-of-line packaging, it is expected that the received order type segment will witness an increased demand during the forecast period.

The food & beverages end-use segment is expected to be the most attractive segment during 2019-2027. Rapid industrialization is the key factor influencing the growth of the end-of-line packaging market. The demand for end-of-line packaging machineries is increasing in food and beverage end-use industries as it reduces the manual handling of products, which reduces the risk of contamination. Electronics & semiconductor, pharmaceuticals, and automotive are some of the key segments in the global end-of-line packaging market.

Grab an exclusive PDF Brochure of this report:

https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=9278

High production costs translate to lower profits. Today, enterprises with profitable businesses are planning to reduce costs to achieve better efficiency. Although capital costs are a major influence in the decision to adopt automation techniques such as end-of-line packaging, in reality, these solutions are proving to be instrumental in decreasing costs along with providing significant increment in production capabilities through increased speed, reduction of bottle necks, and capability to run 24/7. Food packaging industries adopt for automated packaging techniques that enable the staff to avoid performing dangerous and physically demanding tasks, in turn, reducing costly OHS (Occupational Health and Safety) issues.

On the basis of geography, China is expected to be the most attractive market followed by the US and Germany in the end-of-line packaging market. The US and Germany end-of-line packaging market being a comparatively mature market is expected to show slow growth. Key companies functioning in the global end-of-line packaging market are, Bosch Packaging Technology Krones AG, Optima Packaging Group GmbH, Pro Mach Inc., Gebo Cermex, IMA S.p.A., Festo Corporation, Combi Packaging Systems LLC, DS Smith plc, and Schneider Packaging Equipment.