The advent of 3D printing is arguably one of the most disruptive innovations that have emerged over past two decades. Evolving from an optimistic attempt made by Professor Behrokh Khoshnevis, University of South Carolina, to create a 3D printed wall, the inclusion of 3D printing in construction has witnessed immense growth. Moreover, 3D printing is extensively used in various industries, including healthcare, aviation, and engineering. For several decades, the construction sector has remained dormant in terms of technological advancements. However, the introduction of 3D printing in construction has gained tremendous popularity, as more number of stakeholders are recognizing the true potential of this technology. This has considerably driven the 3D printing in construction market over the years.

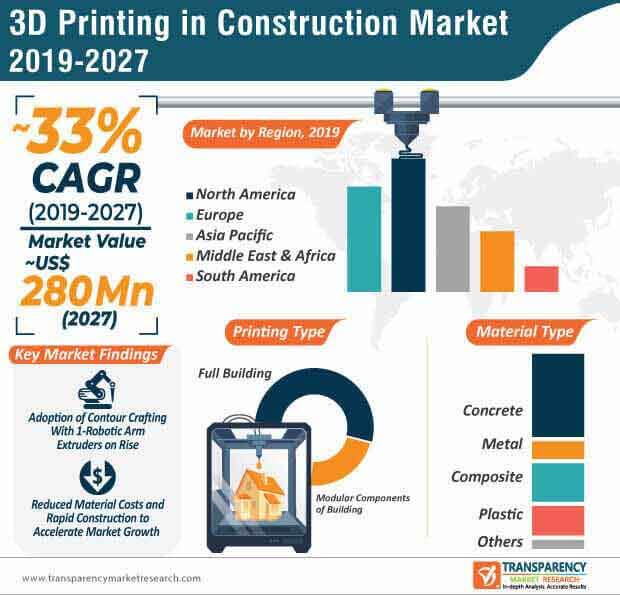

Significant advancements in 3D printing have led to opportunities for the players in the 3D printing in construction market, as 3D printed materials are increasingly being used to build houses. The 3D printing in construction market is expected to gain traction in the coming years, owing to a range of benefits, including reduced material costs, faster construction, significantly lower injuries, and improvements in forms. Due to these benefits, 3D printing in construction market is expected to witness a ten-fold growth during the forecast period and reach a value of ~US$ 280 Mn by 2027 from a modest market value of ~US$ 29 Mn in 2019.

Request a sample to get extensive insights into the 3D Printing in Construction Market

3D Printing to Replace Conventional Construction Techniques

The advent of 3D printing in the construction market has come at a time when the construction sector is aggressively seeking solutions to address a host of problems. According to estimates, the construction sector accounted for nearly 40% of the total waste generated worldwide. Furthermore, civil engineers and architects are largely engaged in negotiating the geometric limitations put forward by the casting process. Drawbacks of manufacturing formworks on job sites, mounting work safety issues, and hurdles in transporting various materials from one location to the other are some of the major issues that 3D printing in construction market could potentially provide answers for.

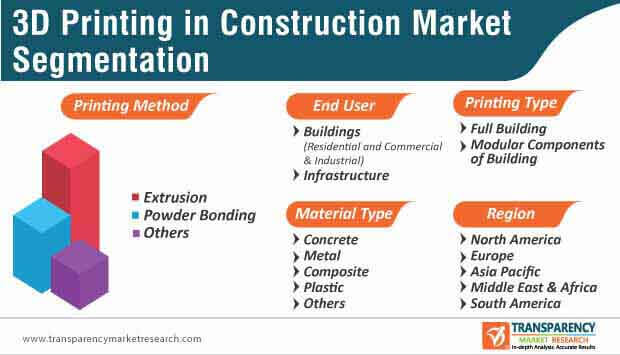

At present, two 3D printing techniques are increasingly being used across the construction industry – power binding and extrusion gantry system printing. Out of these printing techniques, extrusion 3D printing has gained significant acceptance in the construction sector. Thus, in terms of printing method, the extrusion segment is expected to dominate the 3D printing in construction market with an impressive market share of over 70% during the forecast period (2019-2027). Despite the growing adoption of power binding in 3D printing in construction market, stakeholders are likely to adopt the extrusion printing method, which is expected to grow at a CAGR of ~33% during the forecast period.

To understand how our report can bring difference to your business strategy, Ask for a brochure

A recent advancement in the 3D printing in construction market is the entry of robotic arm extruder – a technology that is popularly referred to as contour crafting. This technology is extensively used to develop extra-large structures within the construction sector.

Construction Industry Enters New Era with 3D Printed Houses and Buildings

The entry of 3D printing in construction market is tipped to transform this sector, as more number of stakeholders are vouching for this novel technology. 3D printing in the construction sector offers several benefits, including reduced material waste, cost-effectiveness as it significantly lowers supply costs of traditional raw materials, platform for innovation, and faster production cycles.

At present, 3D printing in the construction sector is being used to develop buildings and other types of infrastructure. Based on end user, the building segment is expected to account for a share of ~73% of the 3D printing in construction market, in terms of value, and is likely to reach a value of ~US$ 205 Mn by 2027. The 3D printing technique is increasingly being used to build residential, commercial, and industrial buildings. For instance, in 2015, Winsun Decoration Design Engineering, a company based in Shanghai, built around 10 residential houses in 24 hours and the company revealed that the cost of building each house was ~US$ 5,000. The roadmap for using 3D printing in construction is being laid down in Dubai wherein the Prime Minister of the United Arab Emirates announced that around 25% of the city’s new buildings would be built using 3D printers by the end of 2025.

Read TMR Research Methodology at: https://www.transparencymarketresearch.com/methodology.html

Read Our Latest Press Release:

- https://www.prnewswire.com/news-releases/affordability-and-beneficial-properties-to-serve-as-vital-growth-factors-for-construction-tape-market-during-forecast-period-of-2020-2030-tmr-301221294.html

- https://www.prnewswire.com/news-releases/global-higher-education-solutions-market-to-thrive-on-growing-popularity-of-cloud-computing-and-high-consumption-of-digital-content-tmr-301219732.html