Engineering Plastic Compounds Market – Snapshot

Engineering plastics are a subset of thermoplastics that are used in high-performance applications. They have the ability to outperform commercial materials, such as wood, metal, or thermoplastics, in one or more areas of application. Engineering plastics are blended with additives and fillers such as antioxidants, antistatic agents, blowing agents, colorants, coupling agents, curing agents, heat stabilizers, UV stabilizers, flame retardants, or nucleating agents to produce engineering plastic compounds. These engineering plastic compounds offer superior physical properties that augment their performance for various automotive, electronics, industrial, medical, and consumer goods applications. Engineering plastic compounds exhibit exceptional properties such as heat resistance, chemical resistance, impact, flame retardancy, and mechanical strength. The global engineering plastic compounds market is expected to expand at a significant pace during the forecast period, driven by increase in production of automotive components and electronic devices. The engineering plastic compounds market was valued at around US$ 190.0 Bn in 2017 and is projected to expand at a CAGR of around 8.0% during the forecast period.

Engineering plastic compounds provide attributes such as self-lubrication, transparency, and cost-effectiveness in the fabrication process. Polyamide (PA) and Polyacetal/Polyoxymethylene (POM) compounds show self-lubricating properties that are favorable for automotive applications. Polyamide (PA) compounds are widely used in oil skimmers, cross gear rails, air inlet manifolds, impact-sensitive engine covers, automotive door closures, under bonnet mechanical parts, connecting rods, hoses for automotive use, fan blades, etc. Polyacetal/Polyoxymethylene (POM) compounds have their applications in fuel storage modules, gearwheels, speaker grills, gears, bearing boxes and bushes, blower fans, ventilation fans and pump parts, etc. Acrylonitrile Butadiene Styrene (ABS) and Polycarbonate (PC) compounds display high rigidity and dimensional stability with outstanding processability in electronic applications. Acrylonitrile Butadiene Styrene (ABS) and Polycarbonate (PC) compounds are used in switch frames, instrument holders, housing, casings, etc. Advancements in material properties of engineering plastic compounds in order to make them multifunctional are expected to drive the global engineering plastic compounds market during the forecast period.

More Trending Reports by TMR:

Reduction in the weight of automobiles results in lower carbon emissions and increase in fuel efficiency and performance of vehicles. Automotive manufacturers are compelled to reduce the weight of their vehicles due to stringent regulations against carbon emissions. Automotive manufacturers are also engaging themselves in the manufacture of electric vehicles, owing to norms imposed against fuel consumption. Engineering plastic compounds are light in weight and are replacing metal components in automotive and industrial applications. Increase in the production of light weight vehicles and rise in awareness regarding electric cars are projected to boost demand for engineering plastic compounds.

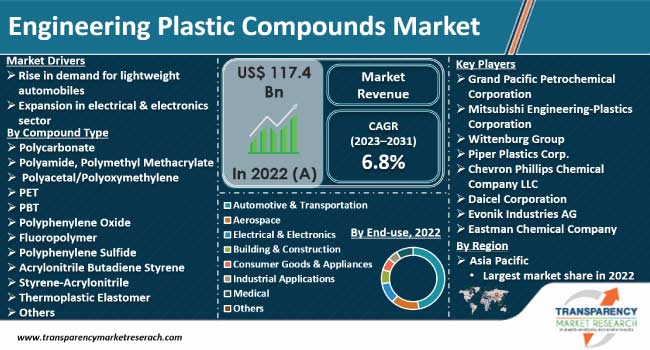

Asia Pacific is a significant region of the engineering plastic compounds market, accounting for a substantial market share. China is a major producer and consumer of engineering plastic compounds. Presence of large OEMs for automotive and electronics industries and existence of a number of small domestic plastic compound manufacturers in the region are expected to drive the engineering plastic compounds market in Asia Pacific. Relocation of manufacturing capacities of automotive components and electronic devices from the western hemisphere to East Asia is anticipated to boost demand for engineering plastic compounds. Rapid industrialization and expansion of automotive and electronics manufacturing plants in India, South Korea, Thailand, and Vietnam are projected to provide an impetus to the global engineering plastic compounds market. The engineering plastic compounds market in North America and Europe is projected to expand at a moderate pace during the forecast period.

Major players operating in the engineering plastic compounds market are Asahi Kasei Corporation, BASF SE, Celanese Corporation, Covestro AG, and RTP, These players are focusing on integrating their suppliers in order to cut down transportation costs and enhance production output. Other prominent players include AKRO-PLASTIC GmbH, Daicel Polymer Ltd., Eurostar Engineering Plastics, Formulated Polymers Limited, Ginar Technology Co. Ltd., HDC HYUNDAI EP COMPANY, KAWASAKI SANKO KASEI Co., Ltd., Ngai Hing Hong Company Limited, Piper Plastics, Inc., Polymer-Group, Polyplastics Co., Ltd., Ravago Americas, Teknor Apex, Trinseo LLC, and WITTENBURG GROUP.

Buy Now:

https://www.transparencymarketresearch.com/checkout.php?rep_id=1388<ype=S

Market Players Gain Promising Demand Opportunities Due to Many Advantages of Engineering Plastic Compounds

Engineering plastics refer to a thermoplastics subset that finds application in various high-performance applications. These products are gaining traction across various end-use industries owing to their ability to offer better results than commercial materials, including metal, thermoplastics, and wood. These engineering plastics are mixed with a wide range of fillers as well as additives in order to manufacture engineering plastic compounds. Antistatic agents, antioxidants, colorants, blowing agents, curing agents, coupling agents, UV stabilizers, heat stabilizers, nucleating agents, or flame retardants are some of the key additives and filled used for the production of engineering plastic compounds.

Engineering plastic compounds can deliver advanced physical properties that boost their performance for numerous electronics, automotive, medical, consumer goods, and industrial applications. Engineering plastic compounds are gathering impetus in various end-use industries such as aerospace, automotive and transportation, building and construction, electrical and electronics, industrial applications, medical, and consumer goods and appliances industry. This growth is on the back of numerous outstanding properties including chemical resistance, heat resistance, flame retardancy, impact, and mechanical strength of engineering plastic compounds. Owing to all these advantages, the vendors in the global engineering plastic compounds market are projected to gather prodigious sales opportunities in the years to come.