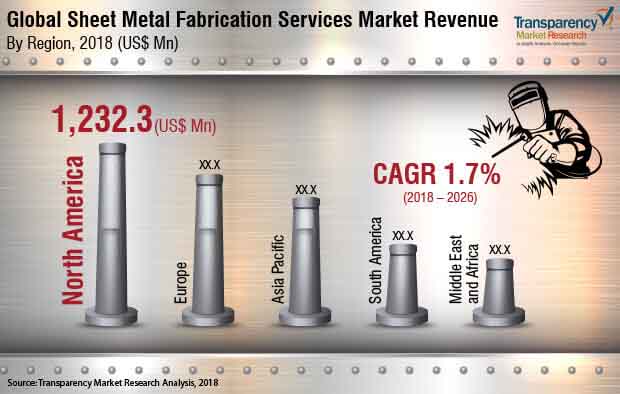

According to a new market report published by Transparency Market Research titled “Sheet Metal Fabrication Services Market – Global Industry Analysis, Size, Share, Growth, Trends, and Forecast, 2018 – 2026,” the global sheet metal fabrication services market is expected to reach US$ 4.4 Bn by 2026, expanding at a CAGR of 1.7% from 2018 to 2026. North America held the highest market share in the sheet metal fabrication services market in 2017.

The sheet metal fabrication services market is witnessing steady growth due to the increased demand from aerospace and aviation industries. Growth in the commercial airlines and defense aircrafts market will drive the sheet metal fabrication services market in the coming years. Demand for advanced technologies in the defense industry will create a favorable environment for the growth of this market in the near future.

Request a Sample – https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=29378

The low-interest rates and low fuel prices were identified as key factors that are responsible for the growth of the automotive market. The outlook for the automotive industry seems promising, with sales growing substantially, without any signs of slowing down. The number of leading automotive and manufacturing industries that employ sheet metal fabrication is growing year on year. Rising demand for iron and steel in the automobile industry has led to the growing significance of sheet metal fabricators. Sheet metal fabrication for the automotive industry typically involves superheating metals and quenching it inside the die itself, resulting in a high-strength metal part with various desirable properties. Advanced laser technology can enable the necessary cutting and trimming of these parts, which may be a big contributor to why this method is gaining popularity.

The sheet metal fabrication services industry is growing. The market is witnessing rise in deployment of CNC machine tools as one of the primary tools to undertake several applications such as shaping and molding. Advancements such as motion control software functions, high-speed smooth tool center point, jerk control, and AI contour control have greatly reduced the cycle time, along with cost reduction per part with augmented ergonomics, thereby increasing the demand for sheet metal fabricated products.

The sheet metal fabrication services market is growing and is highly competitive. Manufacturing, electronics, automobiles, and telecommunication are some of the major industries contributing to the growth of the market. Bending and punching of sheet metal is a common and vital process and has numerous applications which includes machine components, ductwork and industrial systems, architectural and structural components such as filters, panels, downspouts, and tank bodies.