Screen Printing Inks Market: Snapshot

The global screen printing inks market is likely to experience exceptional demand opportunities in the forthcoming years. This growth is attributed to growing use of screen printing in a wide range of end-use industries including automotive, textile, and food and beverages. In addition to this, screen printing is also employed for container printing, toy printing, optical disk printing, and touch panel printing.

Screen printing refers to a printing technique that utilizes a mesh for the transfer of ink onto a substrate. The technique uses various inks including water-based, UV-cured, plastisol, solvent-based, and discharge. In recent few years, there is remarkable growth in preference toward utilizing screen printing over traditional printing techniques as it proffers extended shelf life. This scenario has created prodigious sales opportunities in the global screen printing inks market.

Request Brochure @

https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=60651

Apart from garment printing, screen printing technology is gaining traction across various industries such as packaging. The enterprises from different industrial sectors are growing focus toward making the packing of their products more attractive. As a result, they are utilizing the screen printing technique to achieve attractive product packaging. This strategy is helping enterprises to gain the attention of their customers. Thus, growing use of screen printing in packaging industry is expected to drive prodigious demand opportunities for vendors working in the global screen printing inks market in the years to come.

REQUEST FOR COVID19 IMPACT ANALYSIS –

https://www.transparencymarketresearch.com/sample/sample.php?flag=covid19&rep_id=60651

Screen printing is widely utilized in food and beverages industry. The government bodies of many countries across the globe are imposing stringent regulations and encouraging the screen printing inks manufacturers to develop eco-friendly products. As a result, many companies working in the global screen printing inks market are growing focus toward research and development activities. This factor is likely to drive expansion of the global market for screen printing inks in the forthcoming years.

Screen Printing Inks Market – Snapshot

Various types of inks are used for offset printing, gravure printing, flexography printing, screen printing, and digital printing in the printing industry. Screen printing requires inks such as UV-cured, water-based, solvent-based, plastisol, and discharge. Screen printing is employed for garment printing and other applications in industries such as automotive, textile, and food & beverages. Other applications of screen printing include container printing, optical disk printing, touch panel printing, and toy printing. Screen printing is preferred over traditional printing, as it offers extended shelf life.

High demand for screen printing inks from the packaging industry is anticipated to boost the global screen printing inks market. Macroeconomic factors such as increase in disposable income of the middle class and environmental impact and rise in consumer awareness regarding wellness are some recent trends influencing the global packaging industry. These trends are projected to fuel the screen printing inks market in the near future. Moreover, rise in preference for online reading and growth of the e-commerce industry are likely to boost the demand for screen printing inks market during the forecast period. Factors driving the demand for e-books include mass access, cost advantages over printed books and availability of low-cost reading devices. This is restraining the demand for printed books and boosting the demand for water-borne screen printing inks However, high VOC emissions associated with solvent-based inks is likely to hamper the market. Increase in the number of safety regulations to avoid adverse health consequences resulting from intake of toxic substances is likely to hamper the global screen printing inks market in the next few years. Demand for eco-friendly screen printing inks is creating opportunities in the screen printing inks market.

Buy Now :

http://transparencymarketresearch.com/checkout.php?rep_id=60651<ype=S

The screen printing inks market has been segmented in terms of type, application, and region. Based on type, the market has been segregated into solvent-based, water-based, UV-cured, and others. In terms of volume & value, the UV-cured segment is estimated to expand at a rapid pace, as these inks usually emit less volatile organic compounds (VOCs) and hazardous air pollutants (HAPs). Based on application, the screen printing inks market has been divided into label & packaging, commercial printing, publications, and others. The commercial printing segment is projected to expand at a substantial pace owing to the rise in preference of screen printing inks in commercial printing such as architectural designs, desktop publishing, advertising, fine arts, and textiles.

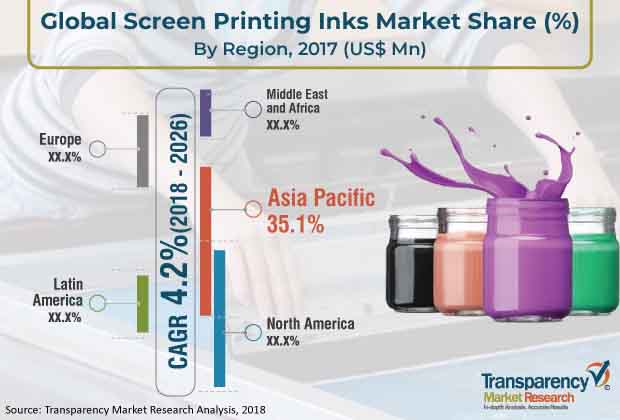

In terms of region, the global screen printing inks market has been split into North America, Europe, Asia Pacific, Latin America, and Middle East & Africa. Asia Pacific accounted for dominant share of the global screen printing inks market in 2017, followed by North America, and Europe. The market in Asia Pacific is anticipated to expand during the forecast period owing to the increase in demand from end-use industries, such as textile, packaging, and automotive, in emerging countries, such as India, Vietnam, Singapore, and Malaysia. North America is anticipated to constitute a significant share of the market during the forecast period. Demand for screen printing inks in North America is expected to increase at a significant pace during the forecast period due to high consumption of UV-cured inks in textile printing, advertising, and automotive component printing applications. The market in the region is dominated by large players and is moderately consolidated. Key players account for a major share of the market. Prominent players profiled in the report include Marabu GmbH & Co. KG, Flint Group, Huber Group, Sun chemicals, Fujifilm Specialty Ink Systems Ltd., Toyo Ink Co., Ltd., Siegwerk Druckfarben AG & Co. KGaA, Kolorcure, Grafco, and Nazdar Ink Technologies.