The antimicrobial laminating film is becoming a rage in the packaging industry amid the coronavirus pandemic. Taghleef Industries (Ti), one of the largest manufacturers of BoPP, CPP, and BoPLA films in the world, is gaining recognition for its Derprosa Antimicrobial laminating film, which has the potential to be effective against coronavirus SARS-CoV-2. Competitor companies in the lamination films market are taking cues from such innovations to increase testing of potential laminating film materials.

Manufacturers in the lamination films market are competing to increase the availability of protective laminated films to stave off viruses, bacteria, and germs. On the other hand, the pandemic has led to business loss for digital printers and advertising technology companies, since events and trade fairs were practically banned or have been rescheduled. Manufacturers are seen diversifying their production and business activities in essential applications such as food & beverage (F&B), pharmaceuticals, and fertilizers, among others, to sustain income sources.

While studying the flexible packaging market before the COVID-19 pandemic, it was found that there was an extensive and consistent demand for the flexible packaging compared to the rigid packaging in terms of product packaging owing to ease & convenience in handling. Moreover, other factors such as cost-effectiveness and low energy requirements while manufacturing flexible packaging films are boosting the demand for flexible packaging.

In addition, majority of the manufacturers is consistently carrying out R&D for innovative solutions in the lamination films market in terms of recyclability and reusability.

Request a sample to get extensive insights into the Lamination Films Market

Meeting Regulatory Requirements, Technical Specifications Important for Market Growth

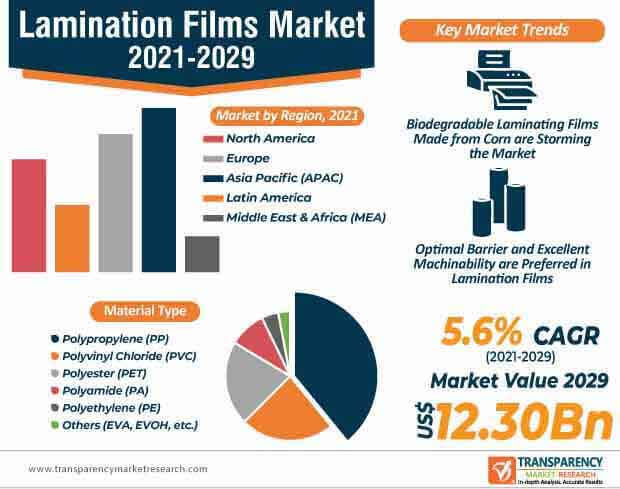

The global lamination films market is projected to reach US$ 12.3 Bn by the end of 2029. However, manufacturers are striving to meet challenging specifications of customers, taking efforts to prevent wastage by protecting customers’ products, and gaining proficiency to meet regulatory requirements. Manufacturers are boosting their production capabilities to meet peel or low seal temperature requirements and other specific film performances.

Manufacturers are working closely with packaging technical specialists, buyers, product managers, and operational managers to continuously renovate and improve their product portfolio. Plastic film packaging company Copol International is meeting regulatory requirements by helping customers lower their environmental footprint with cast polypropylene-based lamination film grades.

To understand how our report can bring difference to your business strategy, Ask for a brochure

Use of Biaxially Oriented Polymer Threads to Produce Quality Biodegradable Laminating Films

Biodegradable and fully compostable laminating films are being developed by companies in the lamination films market. LAM’ON LTD – a start-up in the printing & packaging industry, is being publicized for its 100% biodegradable & fully compostable laminating film and a packaging foil made of corn. Other startups are increasing efforts to draw similar innovations by increasing research in compostable laminating films that prevent VOC (Volatile Organic Compounds) emissions for people producing them, thus promoting a healthy work environment.

Manufacturers are targeting printers and publishers to boost sales of compostable laminating films. Innovative antimicrobial additives based on metallic silver particles are being incorporated in biodegradable lamination films. Manufacturers are offering better quality biodegradable lamination films with the help of biaxially oriented polymer threads, which make films strong, durable, and less prone to tearing.

Robust PE Films Correspond with Strict Requirements of Food Industry

Companies in the lamination films market are increasing their output capacities in polyethylene (PE) lamination films. Coveris – a European packaging company and manufacturer of paper & plastic-based flexible packaging solutions, is building its portfolio in PE lamination films that are being increasingly used as inside and external layer applications. PE lamination films help function as seals or can be used for surface protection. Dairy, pet food, dried food & snacks, and personal care products, among others, are triggering the demand for PE lamination films.

TMR’s Latest News Publication –