Glass Flake Coatings Market – Snapshot

Glass flake coatings possess superior properties such as high tensile strength, high temperature resistance, and excellent moisture resistance. These coatings are commonly employed in critical and complex applications. Glass flake coatings are primarily used in end-use industries such as shipbuilding, oil & gas, power generation, and wastewater treatment. Rise in usage of glass flake coatings in complex and critical applications in industries such as marine, oil & gas, and power generation is propelling the global demand for these coatings. Glass flake coatings possess excellent barrier properties. They also provide reinforcement to substrates from mechanical, thermal, and chemical abrasion. These coatings are also employed in thermal power stations, pharmaceuticals, food and beverages, dyes, wastewater treatment plants, heavy chemicals, and external and internal tanks used in the marine industry.

Request Brochure:

https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=50211

Based on resin type, the global glass flake coatings market has been segmented into epoxy, polyester, and vinyl ester. Epoxy is a widely used type of glass flake coatings. The epoxy segment is expected to dominate the global glass flake coatings market during the forecast period due to the high temperature resistance of epoxy glass flake coatings and their compatibility with different substrates that are used in a wide range of end-use industries.

More Trending Reports by TMR:

In terms of substrate, the global glass flake coatings market has been bifurcated into metal and concrete. The metal segment accounts for major share of the market. Metal substrates are increasingly used in various end-use industries such as petrochemicals, wastewater treatment, and marine. The usage of metal substrates in shipbuilding, offshore & onshore platforms, pipelines, and storage tanks has been rising. This, in turn, is boosting the demand for glass flake coatings in the marine industry. Glass flake coatings minimize the impact of abrasive & corrosive environments over steel substrates. This increases the lifespan of metal substrates. On the other hand, concrete substrate is used widely in the oil & gas industry.

Based on end-user, the global glass flake coatings market has been divided into oil & gas, marine, power generation, industrial, wastewater treatment, and others (paper & pulp, infrastructure, and transportation). Demand for glass flake coatings in the marine industry is rising at a rapid pace, owing to their resistance to high temperature and water; and high tensile strength. Expansion in the shipbuilding industry is also fueling the demand for glass flake coatings. Demand for high-performance coating solutions has increased significantly in shipbuilding projects. These coating solutions are used to protect marine vessels and structures from erosion, fouling, abrasion, saltwater, air, and UV degradation. End-user industries such as oil & gas, power generation, and wastewater treatment are also projected to expand at a rapid pace during the forecast period. Glass flake coatings offer excellent physical and mechanical properties. Therefore, these coatings are suitable for usage in high-end applications in oil & gas and power generation. Power generation is estimated to be a rapidly growing segment of the glass flake coatings market during the forecast period.

REQUEST FOR COVID19 IMPACT ANALYSIS:

https://www.transparencymarketresearch.com/sample/sample.php?flag=covid19&rep_id=50211

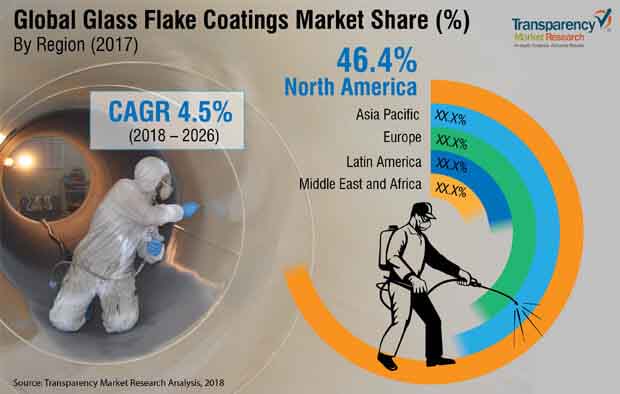

In terms of region, the global glass flake coatings market has been classified into North America, Europe, Asia Pacific, Middle East & Africa, and Latin America. In terms of revenue, Asia Pacific dominated the global glass flake coatings market in 2017. The region is likely to continue its dominance throughout the forecast period. This can be ascribed to the expansion in the shipbuilding industry in developing economies such as China, India, and Singapore. Additionally, growth in the chemical industry is augmenting the glass flake coatings market in Asia Pacific. It is anticipated to be a rapidly expanding region of the market during the forecast period. North America also holds key share of the global glass flake coatings market. The glass flake coatings market in the region is expected to expand at a sluggish pace vis-à-vis that in other regions. Europe constituted significant share of the global glass flake coatings market in 2017. The market in the region is projected to expand at a moderate pace during the forecast period. The glass flake coatings market in Latin America and Middle East & Africa is anticipated to expand at a rapid pace during the forecast period owing to the expansion in the oil & gas industry in these regions.

High degree of competition exists among players operating in the global glass flake coatings market. The market is dominated by large players that are technologically sound. These account for prominent share of the market. The glass flake coatings market is capital and technology intensive. Glass flake coatings are used in high-end applications; therefore, brand image plays a vital role in the market.

Key players operating in the global glass flake coatings market include Akzo Nobel N.V., PPG Industries, Sherwin-Williams, Jotun, and Hempel A/S.

Diverse Properties of Glass Flake Coatings Attract End-Use Industries, Market Likely to Gain Promising Demand Opportunities

Glass flake coatings are gaining traction across various end-use industries owing to a wide range of properties they possess. High temperature resistance, excellent moisture resistance, and high tensile strength are some of the key properties of glass coating flakes. Owing to all these properties, the global glass flake coatings market is experiencing promising demand avenues.

Generally, glass flake coatings are used in complex and critical applications. Oil and gas, shipbuilding, wastewater treatment, and power generation are some of the key end-use industries of glass flake coatings. Thus, increased demand from all these end-use industries is projected to generate promising sales opportunities for vendors working in the global glass flake coatings market in the forthcoming years.

Glass flake coatings are known for their outstanding barrier properties. Apart from this, they offer reinforcement to substrates from thermal, chemical, and mechanical abrasion. As a result, these coatings are in highly preferred in the pharmaceuticals, food and beverages, thermal power stations, dyes, heavy chemicals, external and internal tanks used in the marine industry, and wastewater treatment plants. These strong applications show that the global glass flake coatings market will experience lucrative avenues in the years ahead.

Owing to the recent COVID-19 pandemic, many industrial sectors are experiencing slack in their businesses. As a result, there is remarkable decline in the demand for glass flake coatings from its various end-use industries from all across the world. This scenario has directly impacted the revenues of companies engaged in the global glass flake coatings market. Industry leaders are focused on making key decisions to come out of this critical situation. Many enterprises are continuing their production activities with skeleton staff while following all safety guidelines by regional governments. As a result, glass flake coatings market is likely to recover from this critical period and shortly gather considerable revenues in the years ahead.