Use of Texas Instruments DSP Control Units in Electronic Load Devices Helps Boost Credibility of Emerging Players

Companies are utilizing conventional MOSFET-based dissipative elements that allow electronic load devices to achieve a wide voltage-current operating range within a device’s maximum power rating. This is evident, since high voltage (0V – 1,200V) is expected to be a prominent maximum voltage range segment of the electronic load market. Hence, companies are focusing on heat management in electronic load devices to deploy high density programmable DC power supplies. For instance, Magna Power- an electronics manufacturer in the U.S., is increasing its efforts to boost the uptake of ALx Series MagnaLOAD devices with conservative cooling to ensure longer product life compared to conventional devices.

Manufacturers are increasing efforts to use Texas Instruments DSP control units across power processing stages in electronic load devices. Such technological improvements have catalyzed growth of the electronic load market, and help boost the credibility of emerging players in the global landscape. Unified digital control platforms and fully-digital control loops of these devices are catching the attention of end users.

Request a sample to get extensive insights into the Electronic Load Market https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=75905

Technological Advancements Enable End Users to Virtually Assess Activities of Electronic Loads

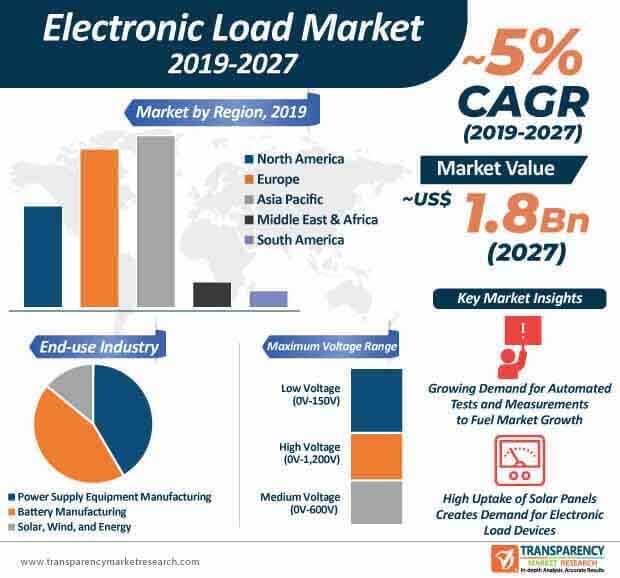

Next-gen software interface is one of the key drivers contributing to the growth of the electronic load market. Companies are introducing software interface that provide intuitive and user-friendly web-browser-based control over the activities of electronic load devices. Programming and measurement through software is gradually becoming mainstream in the electronic load market. This trend has focused on the convenience of end users in the battery manufacturing industry that can virtually control and monitor the software. As such, battery manufacturing end-use industry is anticipated to lead the electronic load market. The electronic load market is estimated to reach a value of ~US$ 1.8 Bn by the end of 2027.

Companies are adopting the server-client software model for access to electronic loads from any device or operating system. Technological advancements have helped companies to establish a network where end users can access the server from any electronic device such as desktops, tablets, and smartphones.

Stakeholders Comply with Safety Standards Using Programmable DC Electronic Loads

Manufacturers in the electronic load market are developing devices that offer versatile functionality in various end-use industries. They are increasing efforts to develop automated test equipment for power discharge testing. These automated equipment are witnessing high demand in power supply and energy industries. As such, power supply equipment manufacturing end-use industry is projected to witness considerable growth in the electronic load market.

The ever-growing energy industry including solar and wind energy, is creating a demand for electronic load devices to thoroughly test power sources of their products. Eco-friendly consumers are adopting home appliances that function on renewable energy such as solar panels and car batteries. Hence, companies in the market are developing programmable electronic loads that are increasingly replacing conventional resistors. Dynamic testing and rapid increasing and decreasing the load in repeatable fashion are some of the practices that stakeholders need to adopt in order to comply with quality and safety standards for their products.

Stuck in a neck-to-neck competition with other brands? Request a custom report on Electronic Load Market https://www.transparencymarketresearch.com/sample/sample.php?flag=CR&rep_id=75905

Companies Enhance Production Capabilities to Increase Availability of E-loads Suited for High Voltages

Several devices today operate at higher voltages such as electric vehicle batteries, silicon-carbide semiconductors, and the likes. These devices have created a demand for electric loads (e-loads) to load them down during testing. However, scarcity of e-loads rated for these high voltages poses as a challenge for companies in the electronic load market. Hence, companies are increasing their production capacities to increase the availability of e-loads that are suited for high voltages.

Companies in the electronic load market are exploring untapped opportunities in electrochemistry to help end users carry out research on batteries and fuel cells. They are increasing research to design e-loads with modular designs and several operating modes for automated test and measurement. Manufacturers are increasing their design efforts to incorporate buttons and knobs for interactive use. They are also introducing USB interface options to carry out automated test and measurement. Moreover, manufacturers are increasing their production capabilities to develop e-loads that can connect with multiple loads to enhance the overall system power capacity.