Supply Shocks Affect Sales of Heat Management Products during COVID-19 Pandemic

Automotive sales have taken a hit during the coronavirus (COVID-19) pandemic. The automotive industry is undergoing supply shocks, since OEMs have temporarily shut down their production activities. This has directly affected business practices in the automotive heat shield market, as the demand for vehicles is experiencing a downtrend. However, automotive sales are anticipated to rise by the end of 2024 as COVID-19 subsides in almost all countries. Heat shield manufacturers are adopting robust contingency plans and taking a comprehensive approach to tackle the global economic crisis.

Heat shield manufacturers are developing innovative sales strategies by predicting various future scenarios. Companies plan to revive their operations in European countries, China, Europe, and Japan where the pandemic has almost reached its end. They are focusing on various strategies related to employee engagement, operational continuity, and cash & liquidity management. These factors are expected to drive the automotive heat shield market during the forecast period.

Request a sample to get extensive insights into the Automotive Heat Shield Market https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=16529

Lightweight Fiber Materials in Shields Improve Performance of Automotive Components

Automotive heat shields are being routinely used in passenger cars and light trucks to deploy flame resistance from components that release excess heat. Companies in the automotive heat shield market are now increasing their focus in professional racecars to broaden their revenue streams. For instance, leading provider of industrial chemicals, synthetic fibers DuPont, is increasing its marketing potentials to bring DuPont™ Nomex® into visibility as a highly durable automotive heat shield. Innovative products are bolstering revenue growth for the market, which is estimated to surpass the revenue of US$ 10.3 Bn by the end of 2030.

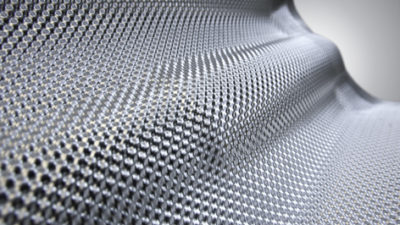

Improving safety and performance of automotive components has become very important for manufacturers in the automotive heat shield market. Hence, manufacturers are increasing their R&D muscle in developing lightweight fiber materials that offer protection against heat and flames. High-temperature automotive applications are fueling the demand for automotive heat shields.

Self-adhesive Automotive Heat Shields Resist Harsh Environments in Vehicles

Self-adhesive heat shields are a novel introduction in the automotive heat shield market. These sheets are being extensively used to protect components from heat sources in vehicles. Innovative self-adhesive heat shields are laminated with pressure-sensitive adhesives (PSA) to improve the performance of automotive components. Multinational manufacturer and distributor of pressure-sensitive adhesive materials Avery Dennison has acquired proficiency in manufacturing self-adhesive automotive heat shields with PSAs that can be mechanically fastened to avoid extra tooling.

Companies in the automotive heat shield market are increasing their production to accommodate slimmer designs spaces in products that reduce rattle and eliminate the need for extra tooling. They are increasing their research expenditure to develop automotive heat shields that adhere to a variety of difficult to bond to substrates. Automotive manufacturers are preferring automotive heat shields that qualify in withstanding harsh environments.

Stuck in a neck-to-neck competition with other brands? Request a custom report on Automotive Heat Shield Market

Nanometric Coating-induced Heat Shields Deploy High Infrared Reflectivity and Corrosion Resistance

Manufacturers in the automotive heat shield market are experimenting with nanometric coatings of aluminum in stainless steel heat shields to increase their thermal efficacy. BS Stainless – a metal fabricator in Walton Summit Centre, England, has introduced its product ShieldMet, which combines the strength and corrosion resistant properties of stainless steel with high reflectivity of aluminum in heat shield applications. Nanometric coatings made from aluminum are being highly publicized to preserve the aesthetical aspect of stainless steel automotive heat shields even under high temperatures.

The high infrared reflectivity of nanometric coatings is being preferred in automotive heat shields. Companies in the automotive heat shield market are increasing their production capacities to develop plasma vacuum coated shields made from stainless steel. Excellent corrosion resistance and formability of nanometric coating-induced heat shields is attracting the attention of vehicle manufacturers.

Ceramic Coatings Enhance Aesthetic Appeal of Automotive Heat Shields

Companies in the automotive heat shield market are increasing efforts to improve the aesthetic appeal of heat shields. For instance, Cerakote – a global manufacturer of thin-film ceramic coatings is tapping incremental opportunities via online sales for its Black Velvet and Burnt Bronze automotive heat shields that can also be used in motorcycle pipes. Manufacturers are establishing their company-owned websites that provide extensive safety data, tech data, and application guidelines to customers buying their products online.

Metallic and velvety finish in automotive heat shields is highly preferred by automobile manufacturers. Companies in the automotive heat shield market are developing products that eliminate the need for catalysts. They are using ceramic coatings that can resist hundreds of Fahrenheit temperature. High temperature coatings are setting the benchmark for innovations in automotive heat shields. Coating manufacturers are increasing the availability of air cured and ready-to-spray coatings that offer cost and time efficiency to automakers.

Manufacturers Educate Automakers about Different Heat Levels to Avoid Degradation of Components

The automotive heat shield market is predicted to advance at a sluggish CAGR of ~4% during the forecast period, as automotive heat shields are associated with several myths regarding their intermittent temperatures and materials. The U.S.-based provider of reflective and insulative solutions Heatshield Products has taken the effort to debunk several myths regarding automotive heat shields by claiming that not all heat shields are the same.

Since different vehicles release different heat levels, companies in the automotive heat shield market are innovating in new materials that qualify to resist high heat levels of vehicles. They are educating technicians and automakers about the difference between excessive conductive, convective, and radiant heat levels. In this way, automakers can choose appropriate heat management products to avoid degradation of automotive components. Heat shield manufacturers are also educating automakers about intermittent temperatures and service temperatures.