Rubber Transmission Belts Market – Snapshot

Power transmission belts are made from low-modulus materials. These materials include leather, rubber, fiber/cotton, and balata. Rubber transmission belts are attached in the form of a loop, which mechanically connects two shafts for transmitting power smoothly. These belts generate power for various applications such as farming, mills, machinery, and automotive. Currently, with the advent of industrial revolution, machines are becoming more complex and sophisticated. There has always been a need to efficiently transmit mechanical power between different parts of machines.

Request A Sample – https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=16850

Key factors driving the demand for rubber transmission belts across the globe are availability of raw materials in abundance, replacement of chain drives with belt drives, and rise in the demand from the automotive industry. Rubber products have been in use since ancient times across the world. Rubber is employed in transmission belts for transmitting power and facilitating the motion between two pulleys or wheels. The consumption of rubber transmission belts is increasing extensively due to rise in the demand for these belts from the manufacturing industry. Moreover, rubber transmission belts are safer than chains. When a chain breaks, wheels get locked, while, in belt drives, the wheel becomes freewheel, which is less risky. High demand for rubber transmission belts in the automotive industry is also driving the market. Different types of belts used in vehicles are timing belts, multi-V-belts, and V-belts. Automotive power transmission is impossible without power transmission belts. The automotive segment of the rubber transmission belts market is expanding, due to high demand for these belts led by their smooth and noiseless operation and cost-effectiveness.

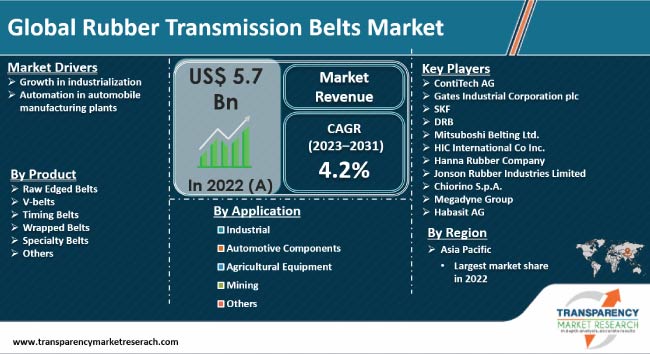

The global rubber transmission belts market has been segmented based on product, application, and geography. Based on product, the market has been classified into raw edged belts, V-belts, timing belts, wrapped belts, specialty belts, and others. The V-belts segment accounts for a major share of the rubber transmission belts market. V-belts include traditional classic belts, narrow-profile belts, and double V-belts. However, all V-belts do not perform the same function. These belts are employed depending on application and objective. Wrapped belts are V-belts wrapped by cotton or polyester. Timing belts are mostly employed to internal combustion engines. Raw edged belts are produced by slicing individual belts from rubber sleeves. Specialty belts are often designed for use in particular applications and thus, they are customized belts.

Based on application, the rubber transmission belts market has been segregated into industrial, automotive components, agricultural equipment, mining, and others. Rubber transmission belts are extensively used in industrial machineries. They are also employed in automotive components and agricultural equipment; however, in quantities lower than industrial machineries. Rubber transmission belts offer various advantages. Hence, it is a highly preferred material in sectors such as industrial, automotive components, agricultural equipment, and mining. In terms of region, the global rubber transmission belts market has been segmented into North America, Europe, Asia Pacific, Middle East & Africa, and Latin America.

Asia Pacific held more than 50% share of the global rubber transmission belts market in 2017. The rubber transmission belts market in North America is anticipated to expand at a CAGR of 1.77% from 2018 to 2026. Growth of the market in North America can be primarily attributed to growth of industries in the region. Growth of the automotive sector in Europe has positively influenced the market for rubber transmission belts in the region.

Leading players operating in the global rubber transmission belts market identified in the research study are ContiTech AG, Gates Industrial Corporation plc, SKF, DRB, Mitsuboshi Belting Ltd., HIC International Co Inc., Hanna Rubber Company, Jonson Rubber Industries Limited, Chiorino S.p.A., Megadyne Group, and Habasit AG.

More Trending Reports by Transparency Market Research – https://www.prnewswire.com/news-releases/global-polyurea-coatings-market-to-grow-at-10-3-cagr-and-attain-valuation-of-us1-82-bn-during-2018–2026-transparency-market-research-301002642.html

Increased Demand from Diverse End-Use Industries Fuels Expansion Opportunities for Rubber Transmission Belts Manufacturers

Rubber transmission belts are gaining traction owing to their ability to generate power for a wide range of end-uses. Thus, there is extensive growth in the use of rubber transmission belts in mills, farming, automotive, and machinery. This factor suggests that the vendors operating in the global rubber transmission belts market will gather promising sales opportunities in the forthcoming years.

Rubber transmission belts are connected in the form of a loop, which is attached to two shafts for the smooth power transmission. With the emergence of industrial revolution, the structure of various types of machines has become sophisticated as well as more complex. This scenario has resulted into increased need for efficient mechanical power transmission between various machines parts. This scenario has created promising demand opportunities for rubber transmission belts market.

Rubber transmission belts are widely used in automotive sector. One of the key elements for this increased demand is the ability of rubber transmission belts to provide noiseless and smooth operation. Apart from this, the cost-efficiency is additional factor stimulating demand for these products. Owing to all these factors, the vendors from global rubber transmission belts market are experiencing lucrative avenues from this industry.

The recent COVID-19 pandemic has shown negative impact on almost every industrial sector including the global rubber transmission belts market. The vendors working in the global market for rubber transmission belts are experiencing many issues related to demand and production activities. As a result, there is notable disruption in the supply chains. All these factors have shown negative impact on the overall revenues of many players working in the global rubber transmission belts market. To lessen the impact of COVID-19 pandemic, many companies across the globe have started their production activities partially. Thus, growing efforts of enterprises to regain their regular activities will help in improving the current business conditions in the global rubber transmission belts market in the upcoming years.

Request for covid19 Impact Analysis – https://www.transparencymarketresearch.com/sample/sample.php?flag=covid19&rep_id=16850