Graphite Electrodes Market – Snapshot

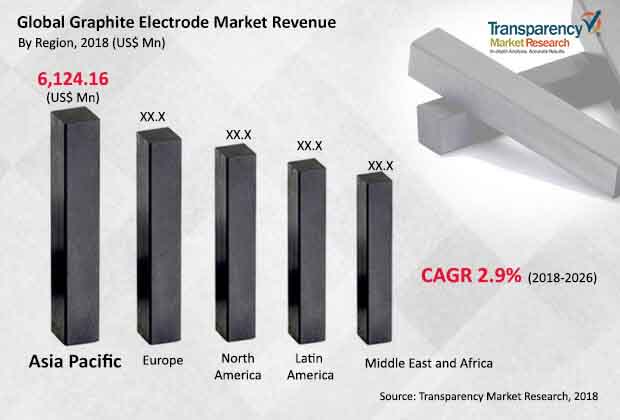

Graphite electrodes are large cylindrical structures made up of needle coke (petroleum coke).These electrodes are available in small or large diameters for high-temperature and high- intensity applications. Graphite electrodes are mainly used for steel manufacturing in electric arc furnaces. They are also used in steel refining and smelting processes. The key application of graphite electrodes is in production of steel and non-ferrous metals. Properties such as high heat resistance, low electrical conductivity, resistance to thermal shock, and low chemical reactivity are anticipated to boost the demand for graphite electrodes. The graphite electrode market was valued at about US$ 10 Bn in 2017 and is projected to expand at a CAGR of 3% during the forecast period.

Request PDF Brochure :https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=23711

Factors such as rise in demand for graphite electrodes in end-use industries, increase in utilization of steel scrap, and high demand from the steel industry are expected to drive demand for graphite electrodes. Graphite electrodes possess favorable electrical properties, high mechanical strength at high temperatures, high electrical and heat conductivity, low impurity content, chemical stability, and high vibrational resistance. Graphite electrodes used in Electric Arc Furnace (EAF) provide flexibility in varying its steel production unlike the blast furnace method of steel production. EAF units can be rapidly started and stopped, allowing the steel mill to vary production according to demand. Due to flexibility, quick turnaround time, and lower fixed costs of EAF, they have gained popularity among steel producers. However, low availability of raw material and fluctuating cost are restraining the graphite electrodes market.

Request For Discount :https://www.transparencymarketresearch.com/sample/sample.php?flag=D&rep_id=23711

Key players in the graphite electrode market need to focus on maintaining raw material supply as supply of needle coke, a key raw material, is fluctuating. Accurate forecast and production planning as per market dynamics are key to the survival in the graphite electrode manufacturing industry.

Major players in the graphite electrode market have adopted mergers and acquisitions as their key strategy to expand their network and share their investments. For instance, in 2017, Tokai Carbon Co., Ltd. acquired SGL GE’s U.S. business to set up a manufacturing base in North America, thereby increasing the company’s presence in a prominent region of the EAF market. The deal is expected to help Tokai build a solid business base as a global competitor, supported by a tri regional structure consisting of bases in Asia, Europe, and North America. When there was oversupply of graphite electrode in the market, Tokai Carbon cut production capacity by 40% to streamline the carbon ceramics segment. However, it hampered the company’s competitiveness in the graphite electrode market. Acquisition of SGL’s U.S. business helped the company increase presence and competitiveness.

Request For Custom Research

https://www.transparencymarketresearch.com/sample/sample.php?flag=CR&rep_id=23711

Approximately six months’ time is required for the production of graphite electrodes. Raw material prices are highly volatile. Hence, contracts with major steel producers with EAF steel manufacturing facilities reduces the risk posed by volatile and uncertain market conditions. Availability of raw material is the main concern for graphite electrode manufacturers. Companies are including the clause of needle coke price adjustment in the contracts for graphite electrode prices.

The graphite electrode market is cyclical in nature. From 2011 to 2016, the market was sluggish due to low demand and oversupply. Owing to these factors, major graphite electrode manufacturers decided to cut production capacity. Global graphite electrode production capacity shrunk. In 2017, prices of graphite electrode surged due to industry consolidation globally, capacity shutdown in China, and rise of EAF-based steel production globally.

The ultra-high power segment accounted for a major share of the graphite electrodes market in 2017. It is expected to remain the dominant segment during the forecast period. Steel & non-ferrous metal and fused materials were the key application segments of the graphite electrodes market in 2017 and are expected to dominate market during the forecast period.

About Us:

Transparency Market Research is a global market intelligence company, providing global business information reports and services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insight for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants, use proprietary data sources and various tools and techniques to gather, and analyze information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.